Method for preparing thick polyvinyl butyral (PVB) film by direct water cooling process

A polyvinyl butyral and film technology, applied in the field of plastic molding processing, can solve the problems of shortened service life, low cooling efficiency, and difficulty in producing film, so as to achieve shortened service life, avoid aging and yellowing, and high production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

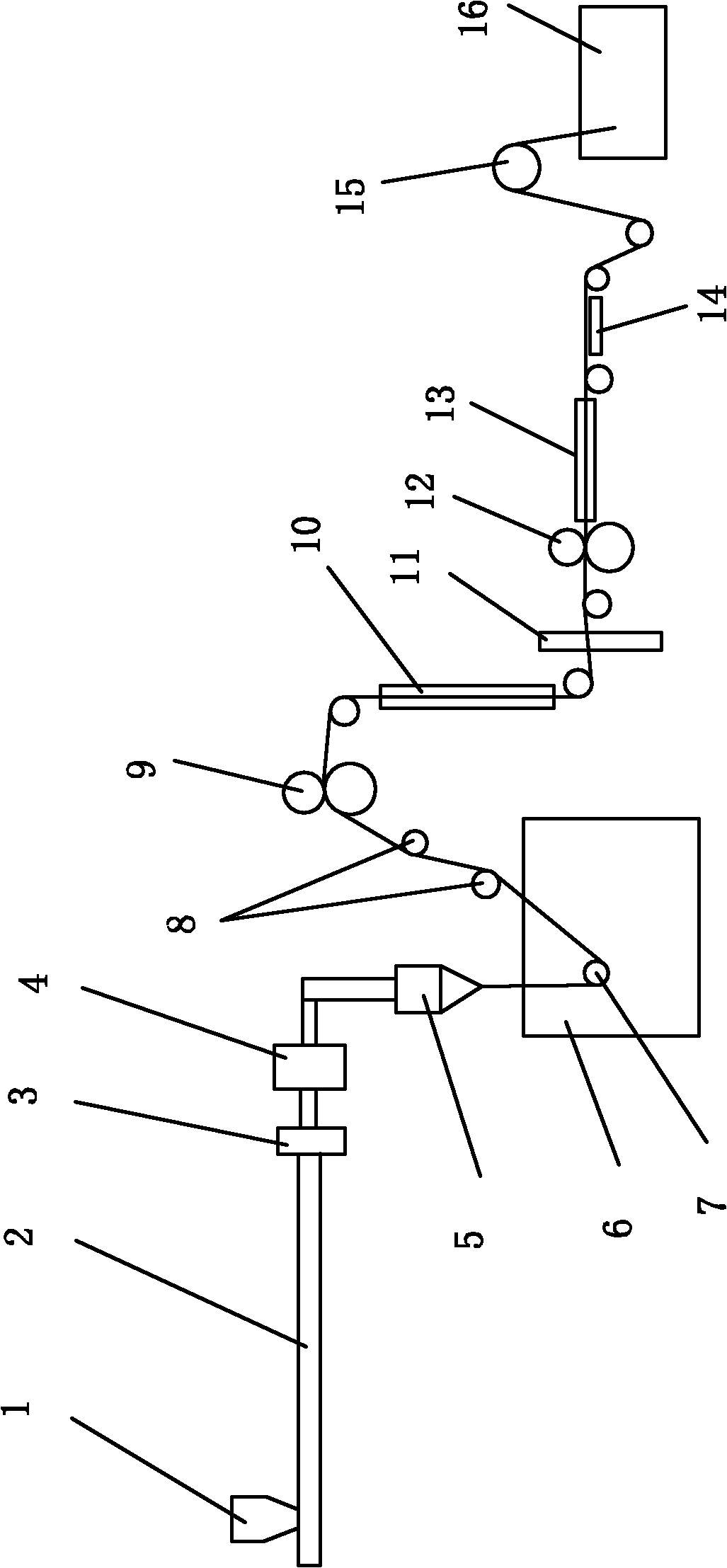

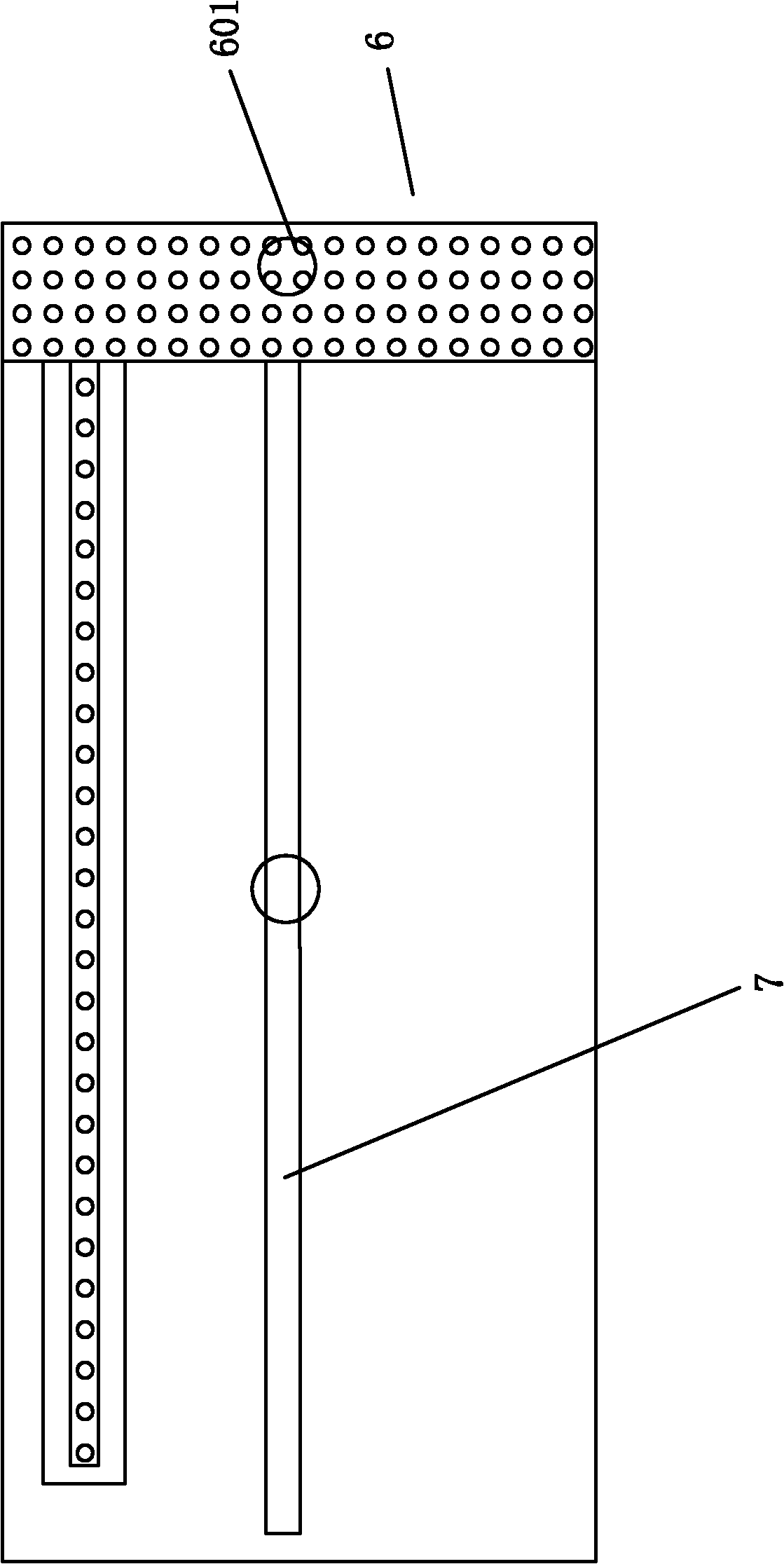

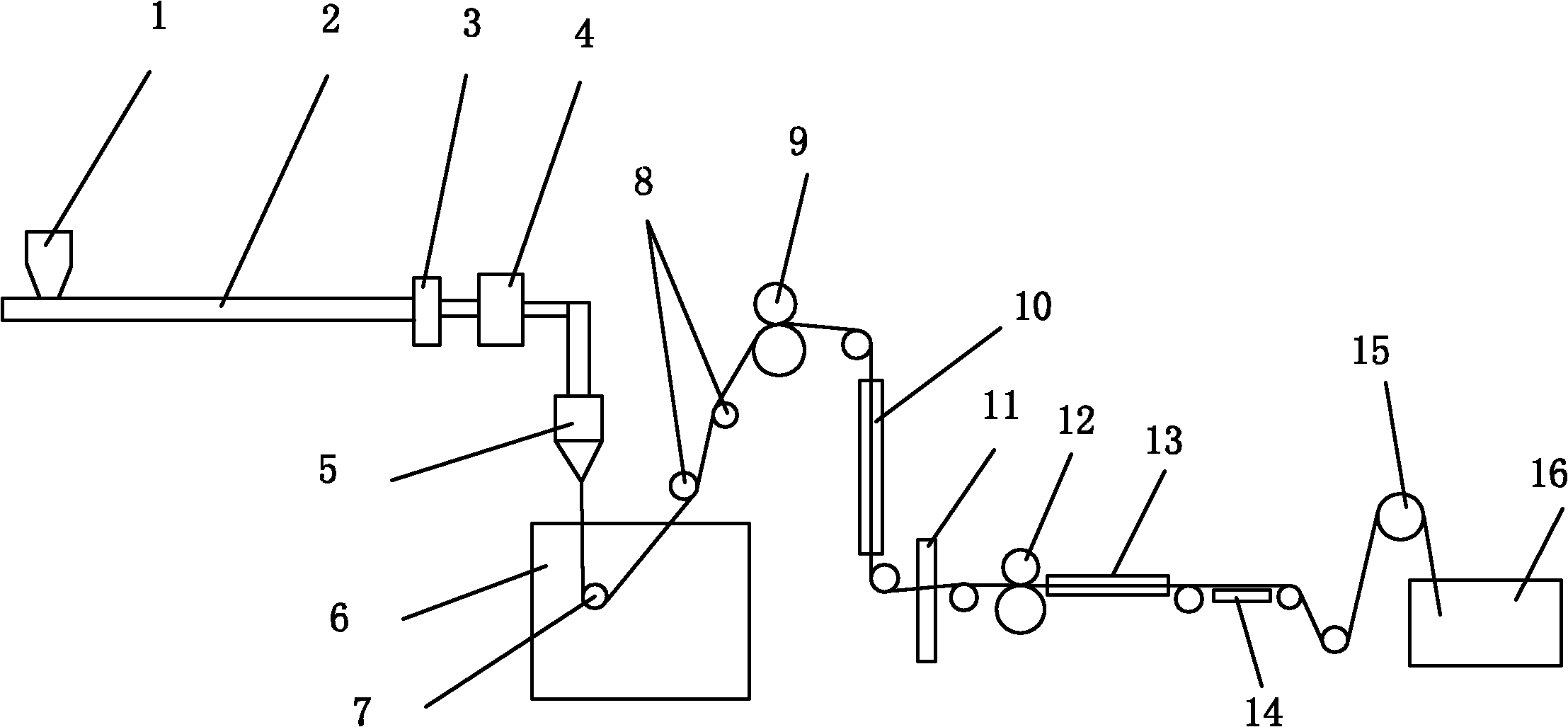

[0022] The present invention will be further described below with specific examples, see Figure 1-2 :

[0023] A method for preparing thick polyvinyl butyral film by direct cooling with water, the specific steps are as follows:

[0024] (1) Mixing: mix PVB resin powder with 17-23% residual hydroxyl content and diester plasticizers and additives on a high-speed mixer. The speed of the high-speed mixer is 400-800rpm, and the mixing time is 8 -12min, calculated on the basis of the dry weight of PVB resin powder in the mixture, containing 25-40% of plasticizer and 10-5000PPM of additives.

[0025] (2) Extrusion and plasticization: Pour the mixture obtained in step (1) into hopper 1, plasticize and extrude in an extruder 2 with an exhaust section, pass through a melt filter 3 to remove impurities, and pass through the melt The pump 4 stabilizes the pressure and extrudes from the T-die head 5. Among them, the screw speed is 20-50rpm, the metering pump speed is 20-40rpm, the feeding sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com