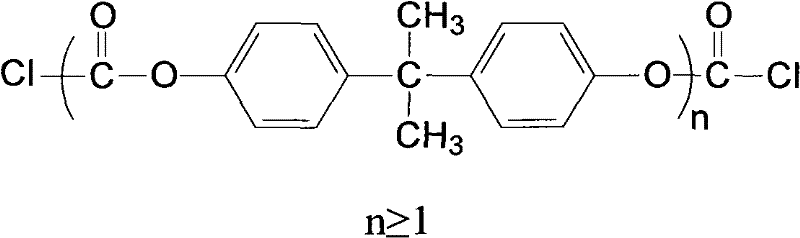

Method for preparing polycarbonate with continuous two-phase interface phosgene method

A polycarbonate and phase interface technology, which is applied in the field of continuous two-phase interface phosgene method to prepare polycarbonate, can solve the problems of complex process, increase the difficulty of the preparation process, large consumption of phosgene and lye, etc., and achieve simplified process control Steps, reducing phosgene alkali hydrolysis rate and lye supplementation, reducing the effect of unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In a mixing tank, 1801 g of bisphenol A, 9558 g of water and 660 g of sodium hydroxide were added to mix and dissolve to form a sodium phenolate brine phase; in another mixing tank, 850 g of liquid phosgene and 13203 g of methylene chloride were added to form an organic phase. The sodium phenolate brine phase and the organic phase, which account for 99% of the total bisphenol A sodium brine phase, are fed into the photochemical reactor composed of a static mixer at a flow rate of 397g / min and 468g / min respectively, and enter after staying for 1.5min. In a coupling reactor that is also composed of a static mixer, the remaining amount of sodium phenolate brine phase and a capping agent with a concentration of 5 wt% are injected into the reactor at the same time, and the capping agent is p-tert-butylphenol Dichloromethane solution, a catalyst with a concentration of 1.5wt%, the catalyst is a dichloromethane solution of triethylamine and a sodium hydroxide solution with a con...

Embodiment 2

[0051] In a mixing tank, 1802g of bisphenol A, 9560g of water and 660g of sodium hydroxide were added to mix and dissolve to form a sodium phenolate brine phase; in another mixing tank, 850g of liquid phosgene and 13205g of methylene chloride were added to form an organic phase. The sodium phenolate brine phase and the organic phase, which account for 99.5% of the total bisphenol A sodium brine phase, are fed into the photochemical reactor composed of static mixers at the flow rates of 399g / min and 468g / min respectively, and enter after staying for 1.5 minutes. In the coupling reactor, which is also composed of a static mixer, the remaining amount of sodium phenolate brine phase, 5% mass fraction of p-tert-butylphenol / dichloromethane solution, 1.5% mass fraction of the Fractions of catalyst triethylamine / dichloromethane solution and 30% mass fraction of sodium hydroxide solution, the flow rates of the four are respectively 2g / min, 12.8g / min, 7g / min, 11g / min, and the reaction is ...

Embodiment 3

[0053] In a mixing tank, 1802 g of bisphenol A, 9559 g of water and 660 g of sodium hydroxide were added to mix and dissolve to form a sodium phenolate brine phase; in another mixing tank, 849 g of liquid phosgene and 13202 g of methylene chloride were added to form an organic phase. The sodium phenolate brine phase and the organic phase, which account for 95% of the total bisphenol A sodium brine phase, are fed into the photochemical reactor composed of static mixer at flow rates of 381g / min and 468g / min respectively, and enter after staying for 1.5min. In the coupling reactor, which is also composed of a static mixer, the remaining amount of sodium phenolate brine phase, 5% mass fraction of p-tert-butylphenol / dichloromethane solution, 1.5% mass fraction of the Fractions of catalyst triethylamine / dichloromethane solution and 30% mass fraction of sodium hydroxide solution, the flow rates of the four are 20g / min, 12.8g / min, 7g / min, 11g / min, and the reaction is 15min. The reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com