Fiber bragg grating (FBG) sensor based transformer fault gas monitoring system

A technology for fiber optic Bragg and transformer faults, applied to instruments, measuring electronics, and measuring devices, can solve problems such as low gas selectivity and monitoring sensitivity, carrier gas or consumable items in chromatographic columns, etc., and achieve long-term monitoring and resolution Oil and gas separation balance is slow and the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0019] 1. Metal coating on the surface of fiber Bragg grating

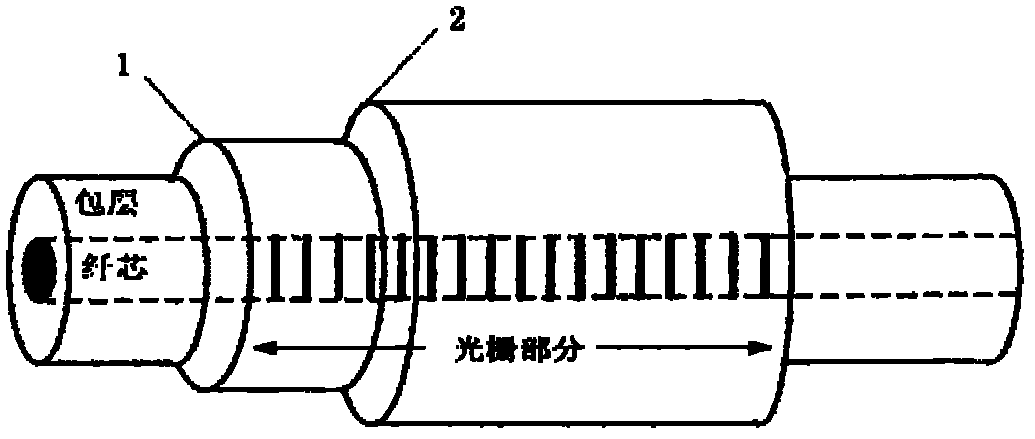

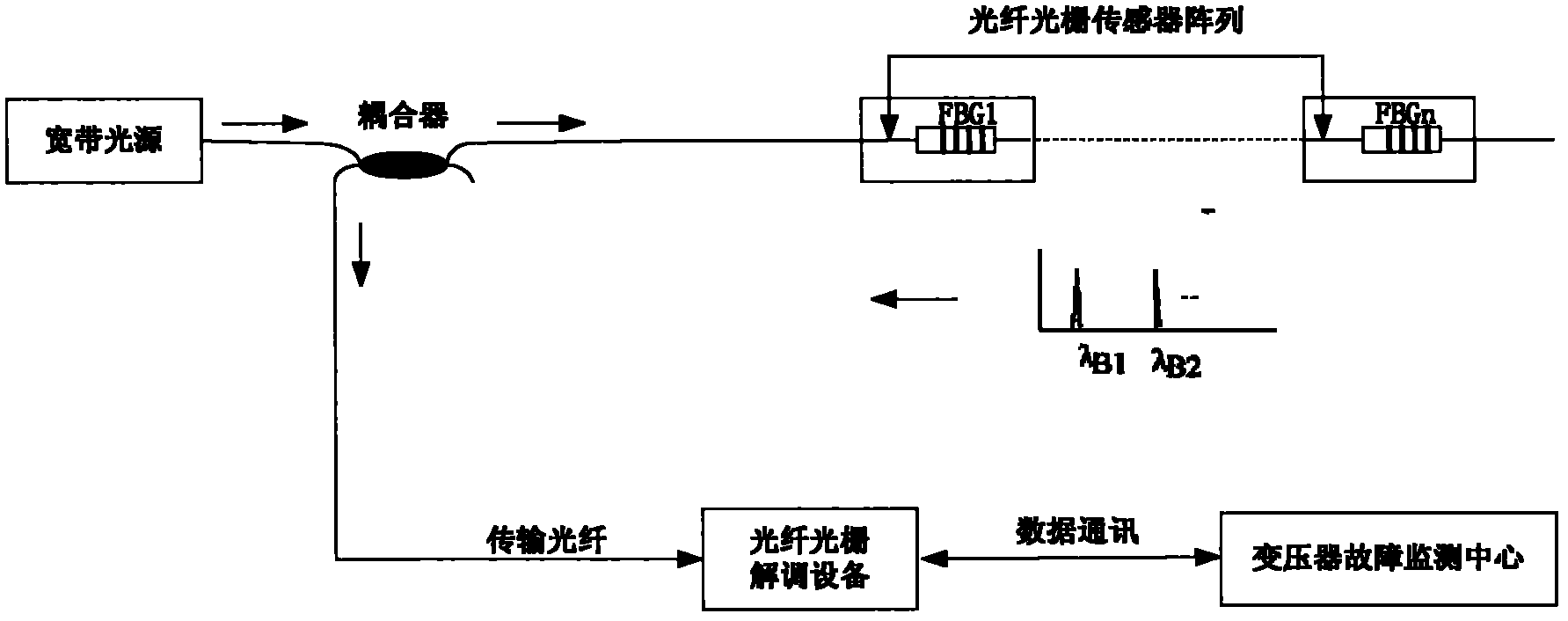

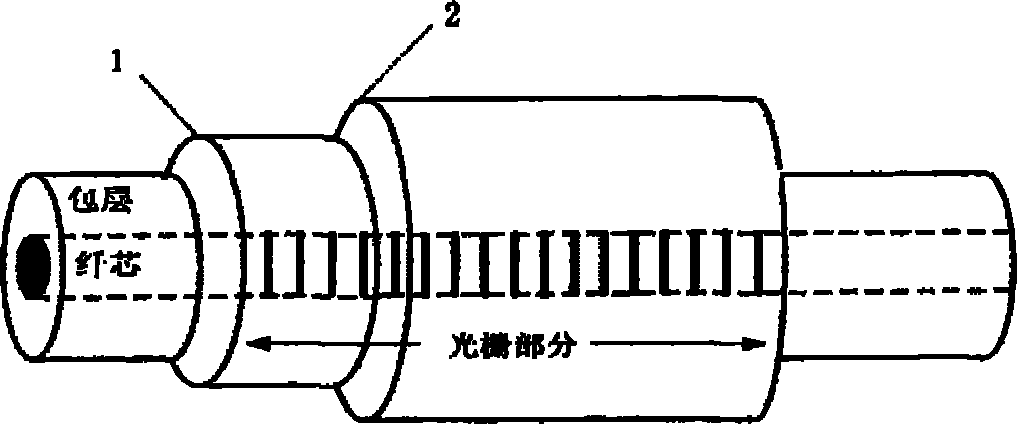

[0020] figure 1 In the above, since the types of metals that can be attached to the surface of the Fiber Bragg Grating are limited, a very thin layer of metal that can be attached to it is first coated on the surface of the Fiber Bragg Grating, and the metal is used to wrap the grating section. In this example, metal gold is used . figure 2 The middle FBG is a Fiber Bragg Grating (Fiber Bragg Grating); λ is the returned central wavelength spectrum.

[0021] 2. Sensor Metal Deposition

[0022] Deposit a layer of a second metal with a certain thickness, such as lanthanum pentanickelide (LaNi5), which is sensitive to special gases, on the gate section wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com