Method for measuring deposition of scales at inner wall of Austenitic boiler tube based ultra-low-frequency vortex

An ultra-low frequency, austenitic technology, applied in the direction of material magnetic variables, can solve the problems of short time limit, interference, poor detection repeatability, etc., to achieve the effect of simple and intuitive operation, low scattering magnetic field, and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

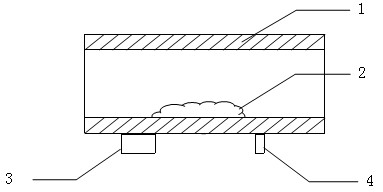

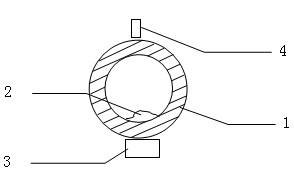

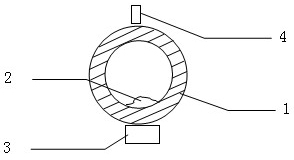

[0031] Such as figure 1 , 2 As shown, a method for measuring scale accumulation on the inner wall of austenitic boiler tube based on ultra-low frequency eddy current includes the following steps:

[0032]1) The excitation coil 3 of the sensor passes an ultra-low frequency current with a resolution of 0.1 Hz and a frequency range of 1 to 40 Hz, and generates an ultra-low frequency alternating magnetic field around the excitation coil 3;

[0033] 2) Attach the sensor to the outer wall of the austenitic boiler tube;

[0034] 3) The ultra-low frequency alternating magnetic field generates eddy currents on the wall of the stainless steel tube 1 of the austenitic boiler. Due to its extremely low frequency, it can be known from the standard penetration depth formula of the eddy currents that the eddy currents have a hindering effect on the alternating magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com