Simulator-based electric control hydraulic type automatic transmission control rule rapid prototyping test bench

A technology of automatic transmission and test bench, which is applied in the field of test bench, can solve the problems of large hardware investment capital, waste of time and material resources, manpower and material resources, etc., and achieve the goal of shortening the development cycle, saving development costs and shortening the development process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

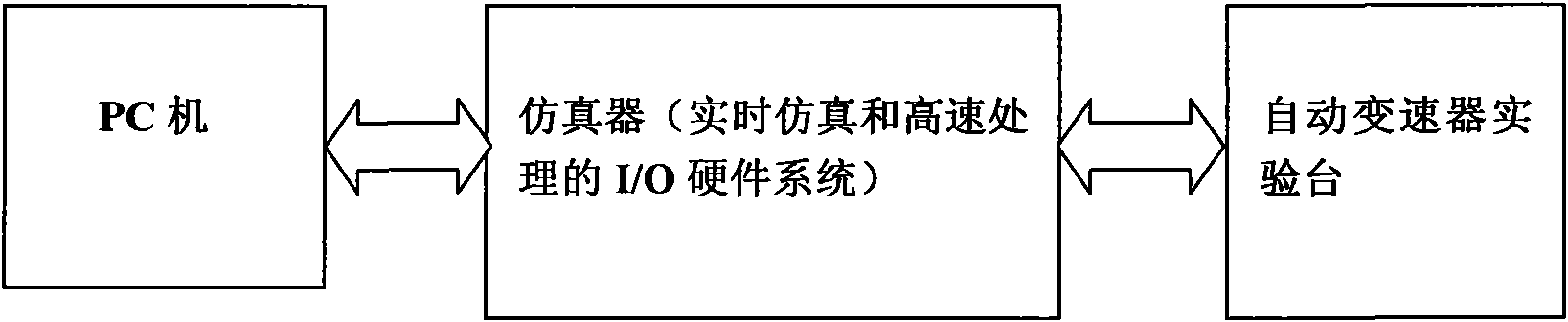

[0028] see figure 1 , the present embodiment is made up of PC, emulator and automatic transmission test bench; Wherein:

[0029] The PC is used for human-computer interaction. The data model of the simulated vehicle is compiled and stored in the simulator through the PC. The PC monitors and records the operation process and results of the entire experimental bench in real time. The PC and the simulator Real-time, two-way data exchange through the CAN data bus;

[0030] The dSPACE real-time simulator used is a set of MATLAB / Simulink-based control system development and testing work platform developed by dSPACE Company, which realizes a completely seamless connection with MATLAB / Simulink. The dSPACE real-time system has a hardware system with high-speed computing capabilities, including processors, I / O, etc., and also has a convenient and easy-to-use software environment for code generation / download and test / debugging. The dSPACE software system includes code generation and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com