Process for degrading cholesterol in yolk

A technology of cholesterol and cholesterol oxidase, which is applied in the field of cholesterol degradation technology in egg yolk, can solve the problem of high cost and achieve the effects of less equipment investment, strong selectivity, and convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After the egg yolk is ultrasonically treated, a certain amount of cholesterol oxidase is added and placed on a shaker for degradation. Ultrasonic-assisted enzymatic degradation of cholesterol in egg yolk, ultrasonic power: 200W, ultrasonic frequency: 50kHz; treatment method: treatment once every 2 minutes, single ultrasonic treatment time is 3 minutes, and the total treatment time is 15 minutes; treatment volume 30ml; cholesterol oxidase The dosage is 0.586U / g (enzyme amount / egg yolk); the degradation treatment time is 9h. Using the above process, the degradation rate of cholesterol in egg yolk is 76.13%.

Embodiment 2

[0033] The study found that the factors that determine the effect of ultrasonic treatment mainly include ultrasonic treatment time, ultrasonic treatment volume, ultrasonic treatment temperature, ultrasonic power and so on.

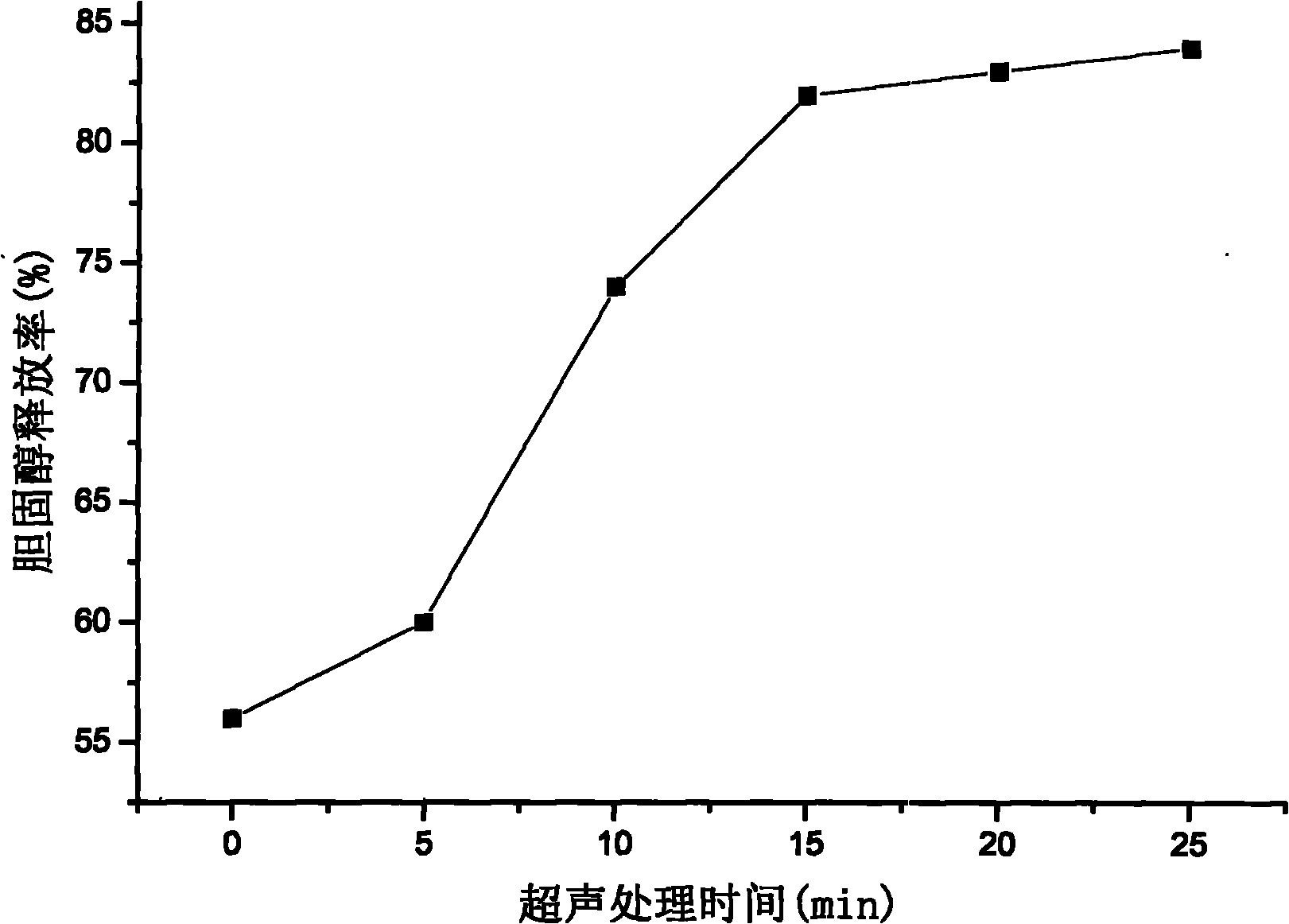

[0034] After the egg is smashed to remove the egg white, the egg yolk is packed into 6 beakers by a certain amount (30ml). Use a 200W, 50kHz ultrasonic instrument to crush for 0, 5, 10, 15, 20, and 25 minutes respectively, and determine the cholesterol content by HPLC. See the relationship between ultrasonic treatment time (minutes) and cholesterol release rate (%) figure 1 shown.

[0035] Depend on figure 1 According to the analysis, the separation of cholesterol and phospholipids in egg yolk is more complete with the prolongation of crushing treatment time. After 15 minutes of ultrasonication, the release rate of cholesterol increases slowly, which may be due to the complete separation of cholesterol and phospholipids. Appropriately prolonging the ult...

Embodiment 3

[0037] The degradation time of cholesterol in egg yolk is generally longer, about 13 hours, and the thermal stability of cholesterol oxidase is poor. When it is kept at 37°C for a long time, the enzyme activity will be greatly reduced. Therefore, shortening the reaction time can not only save costs, but also Enzymes can maintain high activity.

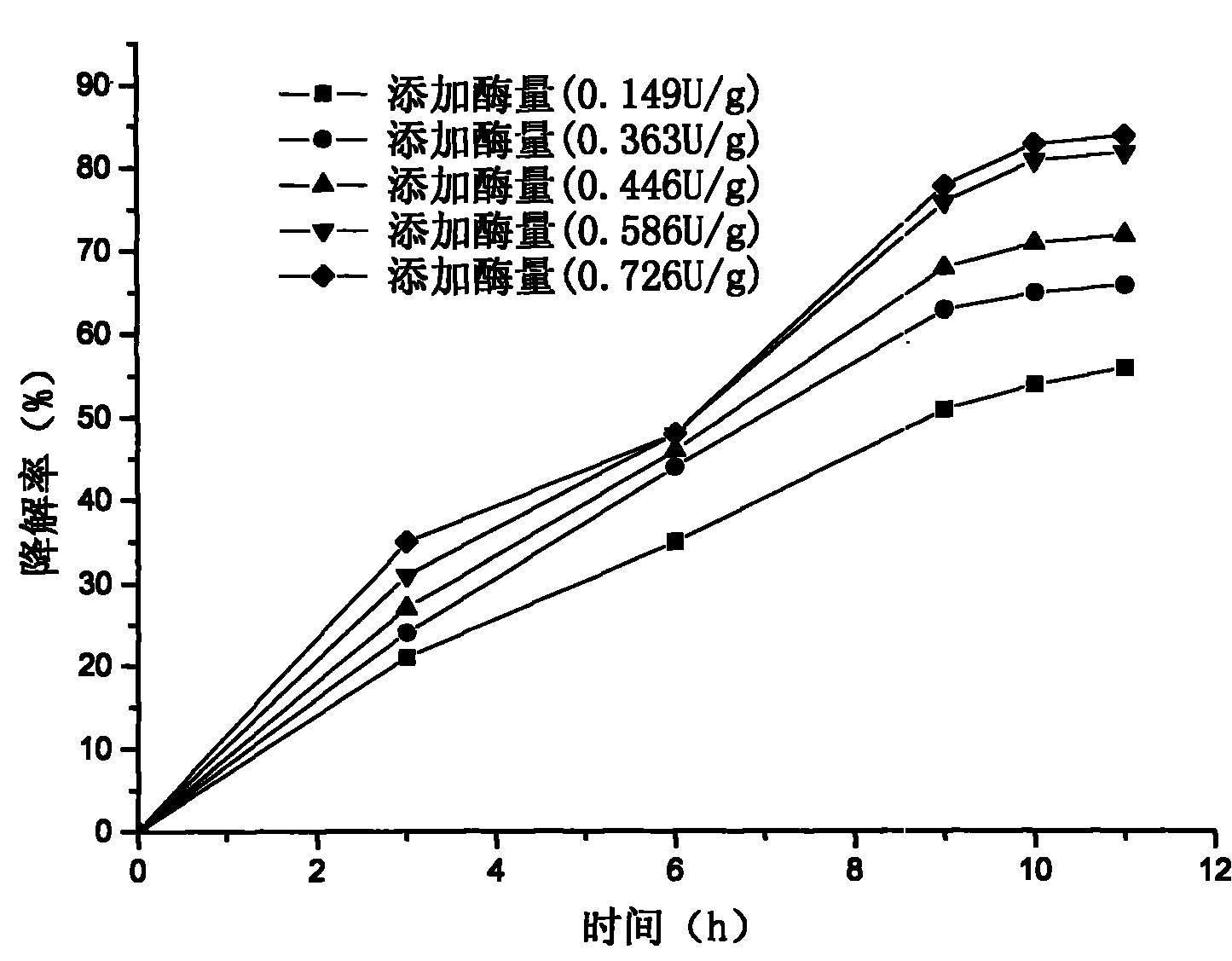

[0038] Get the egg yolks that have been processed according to the method of Example 1 and put them into 4 beakers in a certain amount, add 0.149U, 0.363U, 0.446U, 0.586U and 0.726U to each gram of egg yolks to add enzyme solution, take samples every 3h, measure The conversion rate of cholesterol was obtained, and the optimal enzyme amount and processing time were determined.

[0039] The relationship between the amount of enzyme added, the degradation time and the degradation rate is as follows: figure 2 shown. With the prolongation of enzymatic hydrolysis time, the degradation rate of cholesterol increased gradually, and when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com