Recycling method for treating sludge containing heavy metals

A technology for heavy metal sludge and treatment methods, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

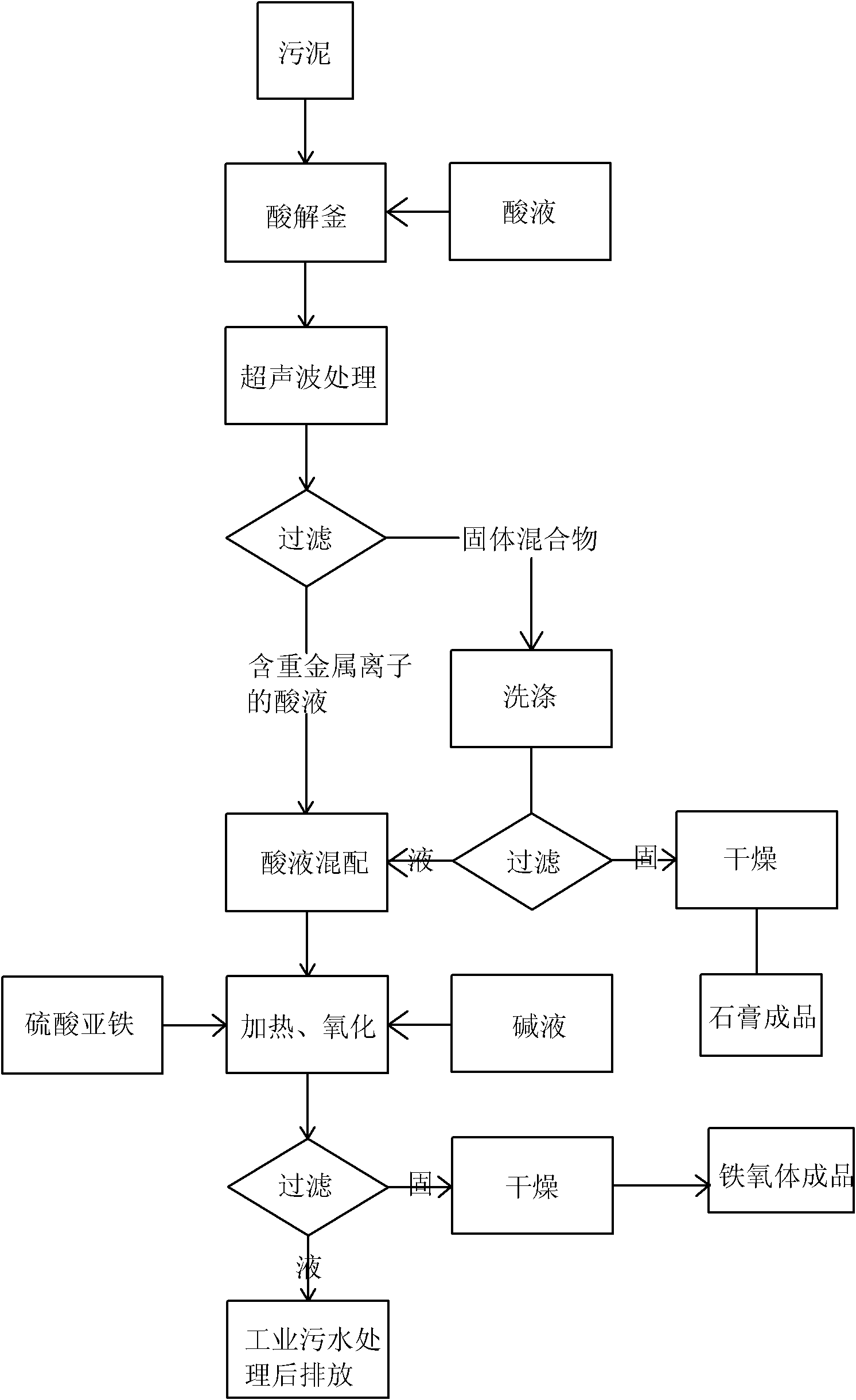

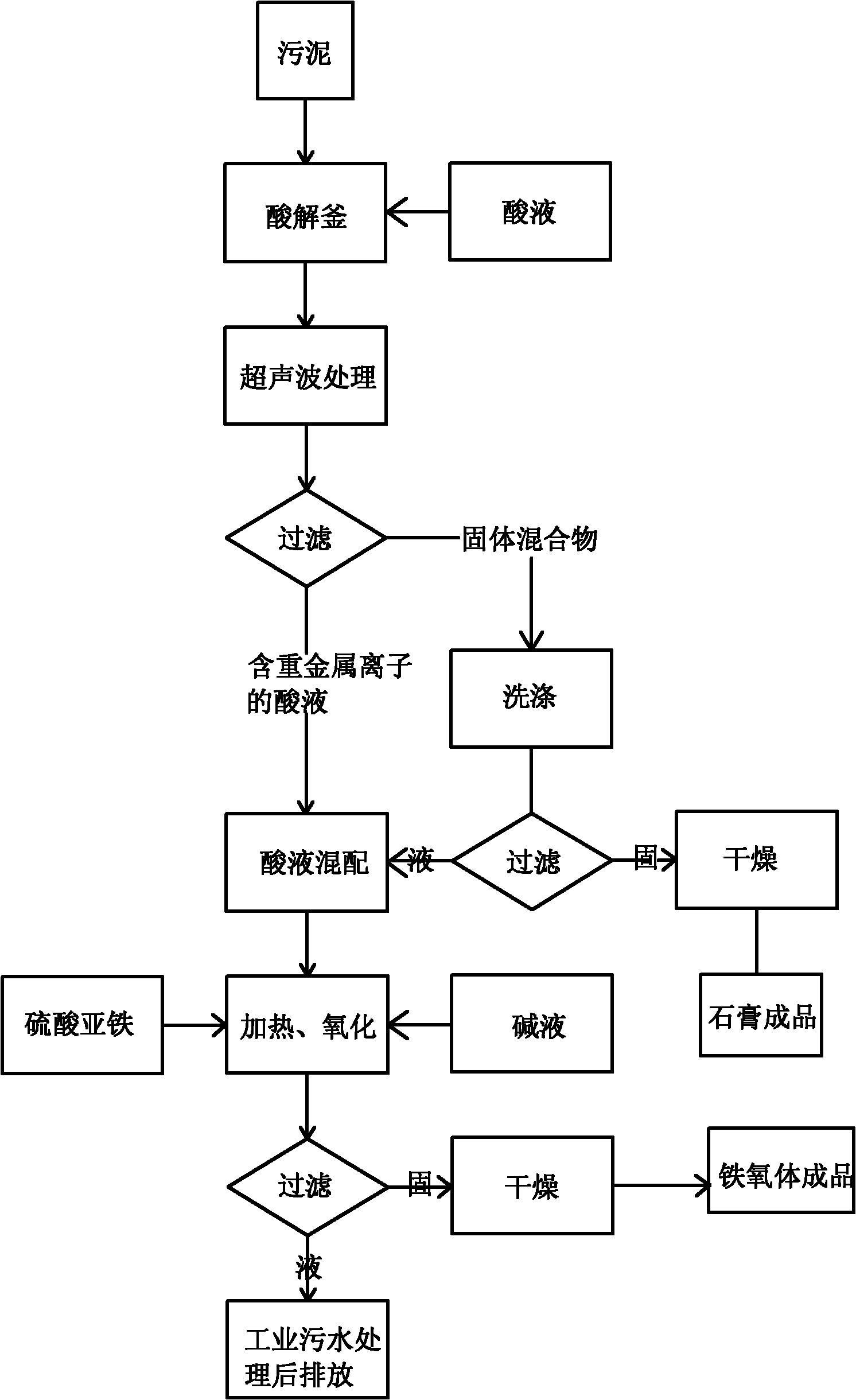

Method used

Image

Examples

Embodiment 1

[0029] A resourceful treatment method for sludge containing heavy metals, comprising the following steps:

[0030] 1. Use mechanical chopping to cut the large solids containing heavy metal sludge into small particles with a particle size of 5-10mm, so that the sulfuric acid in the subsequent treatment steps can fully acidify and leach heavy metals ion;

[0031] 2, according to the ratio of 1: 0.3 by volume ratio of heavy metal-containing sludge and sulfuric acid, adding weight percent concentration in the acidolysis kettle is 50wt% sulfuric acid, sulfuric acid can be industrial sulfuric acid or waste sulfuric acid, then the small particles prepared in step 1 containing The heavy metal sludge is continuously or batch-wise added to the acidolysis tank. During the feeding process, mechanical stirring from top to bottom and mechanical stirring along the circumference are always used; during the reaction process, the feeding speed is controlled to keep the reaction temperature in t...

Embodiment 2

[0040] A resourceful treatment method for sludge containing heavy metals, comprising the following steps:

[0041] 1. Use mechanical chopping to cut the large solids containing heavy metal sludge into small particles with a particle size of 5-10mm, so that the sulfuric acid in the subsequent treatment steps can fully acidify and leach heavy metals ion;

[0042] 2, according to the ratio of 1: 0.4 in the volume ratio of heavy metal-containing sludge and sulfuric acid, add weight percent concentration in the acidolysis kettle and be 40wt% sulfuric acid, sulfuric acid can be industrial sulfuric acid or waste sulfuric acid, then the small particles prepared in step 1 containing The heavy metal sludge is continuously or batch-wise added to the acidolysis tank. During the feeding process, mechanical stirring from top to bottom and mechanical stirring along the circumference are always used; during the reaction process, the feeding speed is controlled to keep the reaction temperature...

Embodiment 3

[0051] A resourceful treatment method for sludge containing heavy metals, comprising the following steps:

[0052] 1. Use mechanical chopping to cut the large solids containing heavy metal sludge into small particles with a particle size of 5-10mm, so that the sulfuric acid in the subsequent treatment steps can fully acidify and leach heavy metals ion;

[0053] 2, according to the ratio of 1: 0.5 in the volume ratio of heavy metal-containing sludge and sulfuric acid, it is 30wt% sulfuric acid to add weight percentage concentration in the acidolysis kettle, sulfuric acid can be industrial sulfuric acid or waste sulfuric acid, then the small particles prepared in step 1 containing The heavy metal sludge is continuously or batch-wise added to the acidolysis tank. During the feeding process, mechanical stirring from top to bottom and mechanical stirring along the circumference are always used; during the reaction process, the feeding speed is controlled to keep the reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com