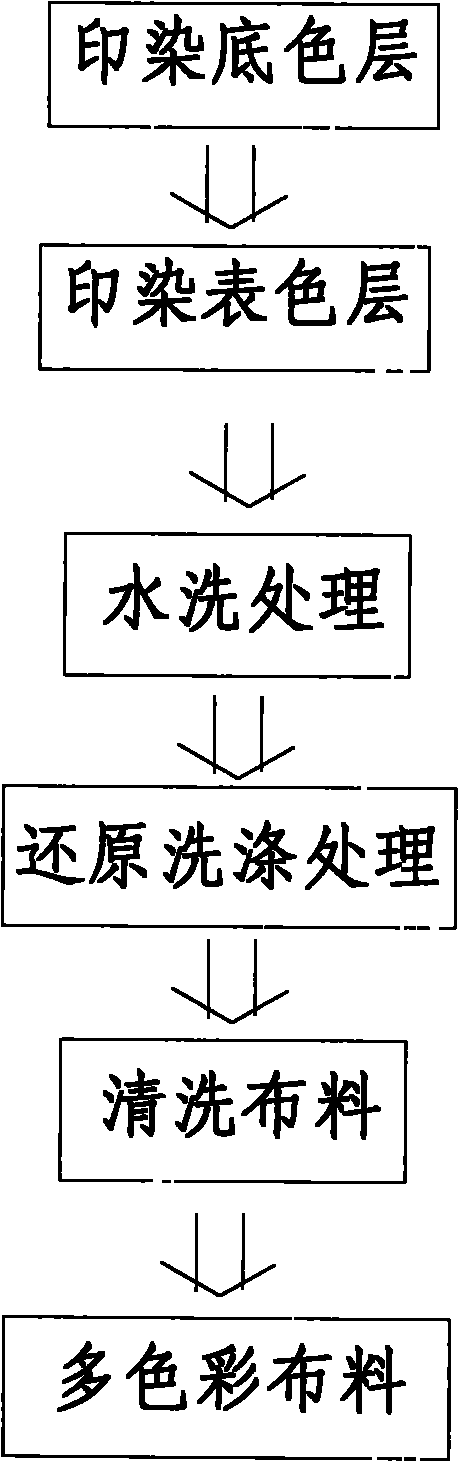

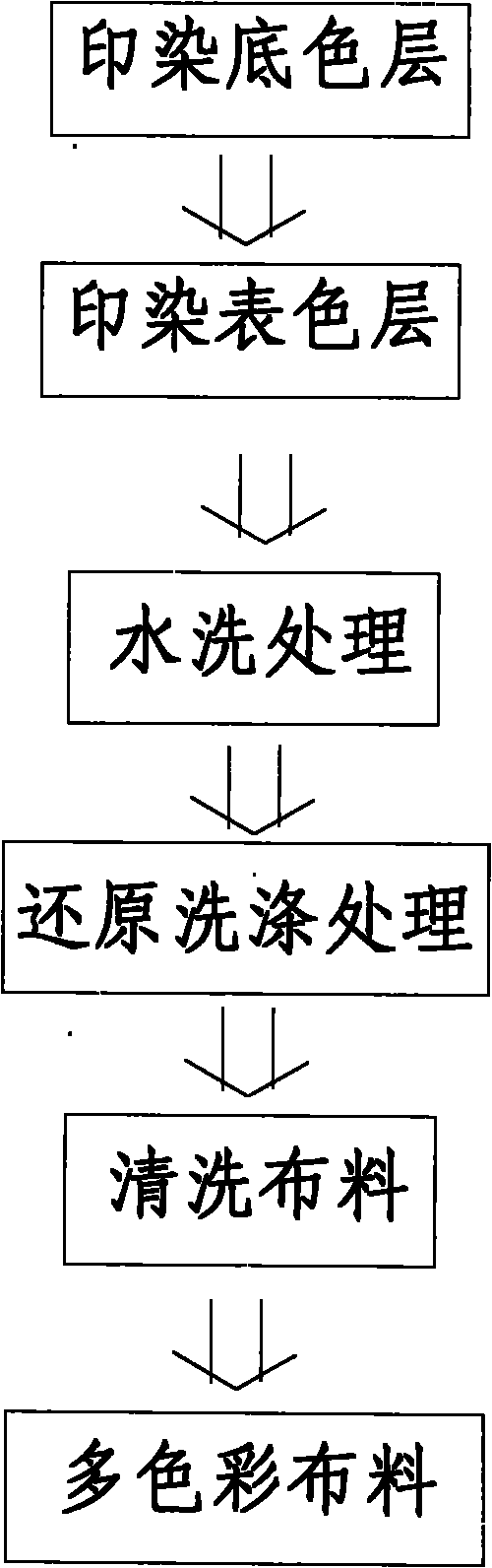

Printing and dyeing process of multi-color cloth

A printing and dyeing process and multi-color technology, applied in the field of printing and dyeing, can solve the problems of single dyeing effect and poor color layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] When the fiber body material is nylon, the base color layer adopts disperse dyes, and the surface layer adopts sulfur dyes. The steps of the printing and dyeing process are as follows:

[0022] a. Printing and dyeing base color layer, the base color layer adopts disperse dye disperse blue to cooperate with leveling agent, diffusing agent and acetic acid solution to improve printing and dyeing effect;

[0023] b. Printing and dyeing surface color layer, the surface color layer is dyed with sulfur dye sulfur red and sodium sulfide reducing agent;

[0024] c. Washing treatment, using fossil washing, snow washing or enzyme washing process, to make the surface color layer of the fabric produce irregular fading effect or make the surface of the fabric have a dilapidated effect or make the fabric produce a gentle fading effect, from the surface to the inner color is violet-purple-blue;

[0025] d. Reduction washing treatment, using 28% acetic acid and 27% hydrogen peroxide to...

Embodiment 2

[0028] When the fiber body material is acrylic fiber, cationic dyes are used for the base color layer, and sulfur dyes are used for the surface layer. The steps of the printing and dyeing process are as follows:

[0029] a. Printing and dyeing base color layer, the base color layer adopts cationic dye Cationic Bright Yellow 7GL combined with leveling agent, diffusing agent and anhydrous sodium sulfate to improve printing and dyeing effect;

[0030] b. Printing and dyeing surface color layer, the surface color layer is dyed with sulfur dye sulfur brown and sodium sulfide reducing agent;

[0031] c. Washing treatment, using snowflake washing, so that the surface color layer of the fabric will produce an irregular fading effect, and the color from the surface to the inside is light brown-brown yellow-yellow;

[0032] d. Reduction washing treatment, using 28% acetic acid and 27% hydrogen peroxide to wash and remove the residual oxidant on the surface of the cloth, wherein the redu...

Embodiment 3

[0035] When the fiber body material is viscose, vat dyes are used for the background layer, and sulfur dyes are used for the surface layer. The steps of the printing and dyeing process are as follows:

[0036] a. Printing and dyeing base color layer, the base color layer adopts vat dye vat blue HSM combined with leveling agent, diffusing agent and acetic acid solution to improve the printing and dyeing effect;

[0037] b. Printing and dyeing surface color layer, the surface color layer is dyed with sulfur dye sulfur black and sodium sulfide reducing agent;

[0038] c. Washing treatment, using fossil washing, so that the surface of the fabric has a dilapidated effect and a faded effect pattern, and the color from the surface to the inside is dark blue-blue-black-blue;

[0039] d. Reduction washing treatment, using 28% acetic acid and 27% hydrogen peroxide to wash and remove the residual oxidant on the surface of the cloth, wherein the reduction washing temperature is 40°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com