Detonation tube structure of multi-tube pulse detonation engine

A technology of pulse detonation and detonation tube, which is used in mechanical equipment, intermittent injection devices, etc., can solve the problems of high ignition energy and simple structure, and achieves the goal of weakening strength, maintaining synchronization, and reducing pressure back-propagation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

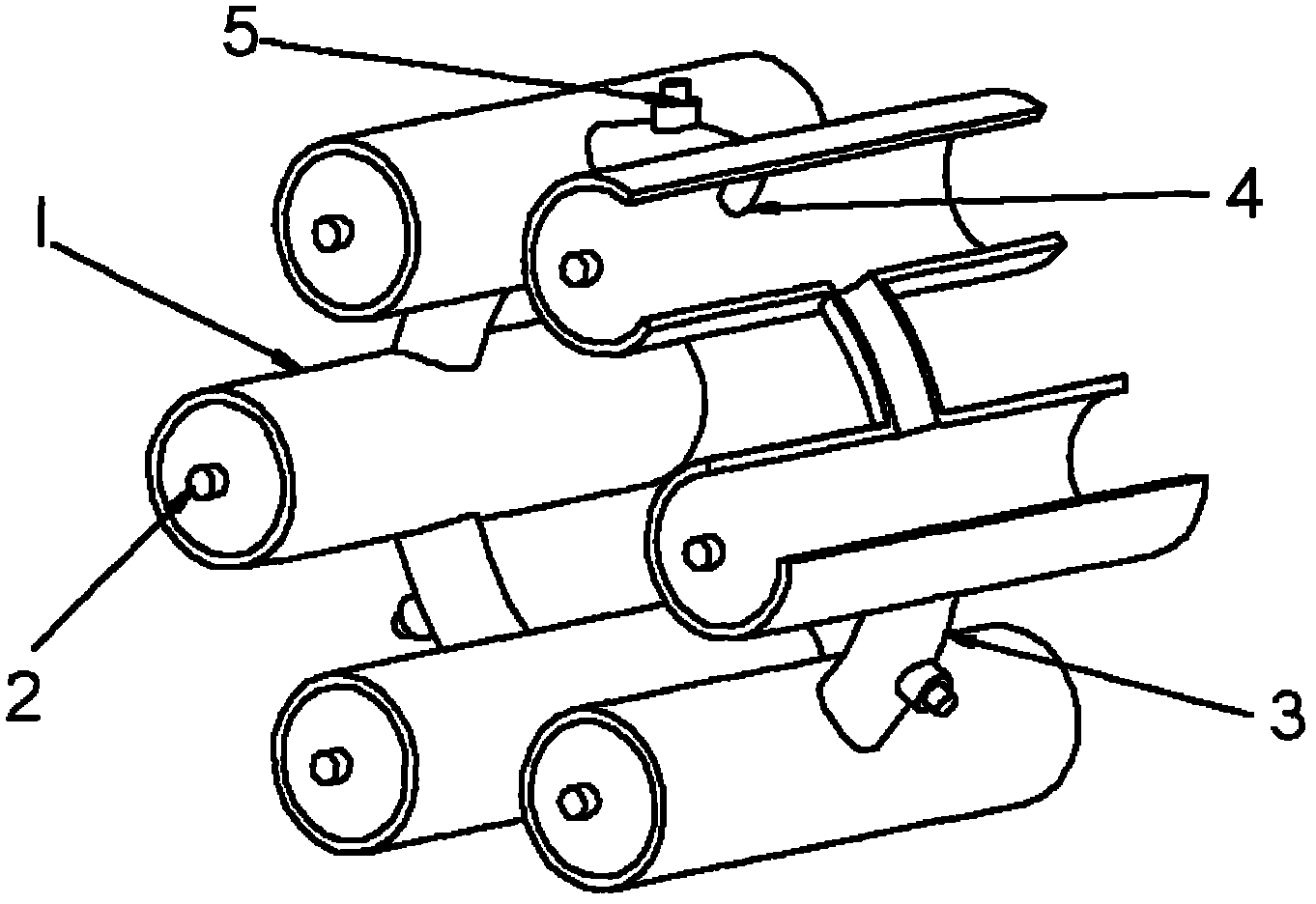

[0015] The detonation tube structure of the multi-tube pulse detonation engine in this embodiment includes 6 detonation tubes 1, the inner diameter of a single detonation tube is 50 mm, the wall thickness of the tube is 4 mm, and the total length of a single detonation tube is 1500 mm; The central axes of the shock tubes are evenly distributed along the circumferential direction, that is, the central axes of the six detonation tubes are on the same circumferential surface, the circumference diameter is 250mm, and the central angles of the central axes of the two adjacent detonation tubes are the same as 60° .

[0016] The two adjacent detonation tubes are connected through the cross-fire tube 3, each cross-fire tube 3 is arc-shaped, and the radius of the arc is the same as 125mm, and the central axis length of each cross-fire tube 3 is 72.8mm , which is 1.26 times the outer diameter of the detonation tube. The inner diameter of the cross-fire tube is 20mm, which is 0.4 times ...

Embodiment 2

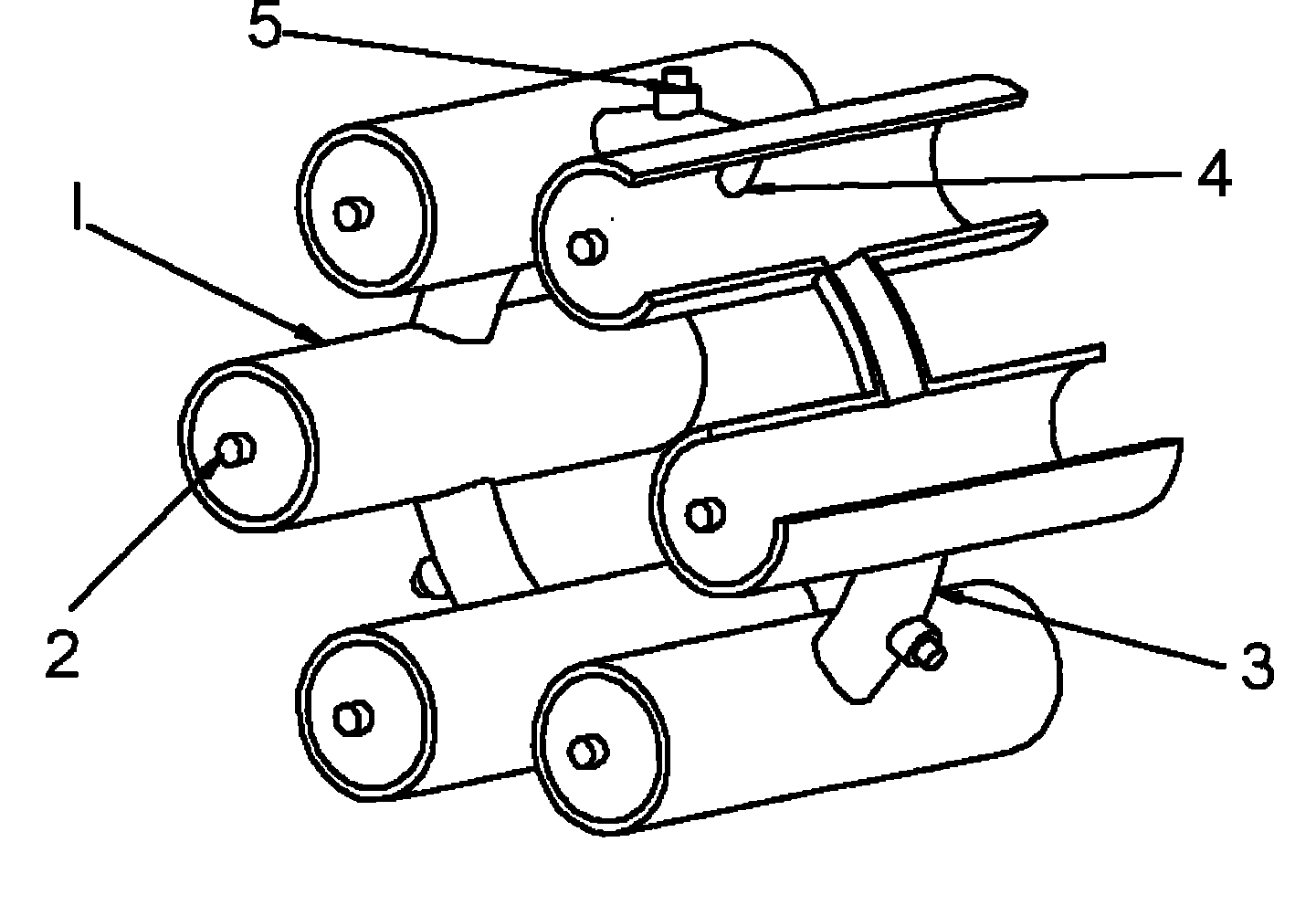

[0019] The detonation tube structure of the multi-tube pulse detonation engine in this embodiment includes 6 detonation tubes 1, the inner diameter of a single detonation tube is 40mm, the tube wall thickness is 4mm, and the total length of a single detonation tube is 1500mm; The central axes of the shock tubes are evenly distributed along the circumferential direction, that is, the central axes of the six detonation tubes are on the same circumferential surface, the circumference diameter is 250mm, and the central angles of the central axes of the two adjacent detonation tubes are the same as 60° .

[0020] The two adjacent detonation tubes are connected through the cross-fire tube 3, each cross-fire tube 3 is arc-shaped, and the arc radius is the same as 125mm, and the central axis length of each cross-fire tube 3 is 82.8mm , which is 1.73 times the outer diameter of the detonation tube. The inner diameter of the cross-fire tube is 40mm, which is 1 times the inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com