Dimeticone emulsion and preparation method thereof

A technology of simethicone emulsion and simethicone, which is applied in the direction of medical formula, emulsion delivery, and medical preparations of non-active ingredients, etc., which can solve the inconvenience of infants and young children, the inconvenience of the discharge of tiny bubbles in the gastrointestinal tract, and the restriction of gastric Relief of flatulence and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

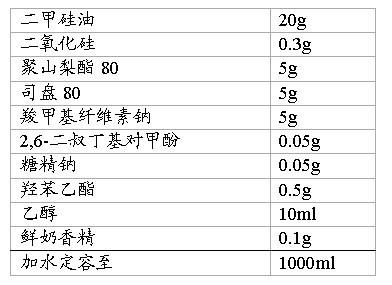

[0020] 1. Prescription:

[0021]

[0022] 2. Process steps:

[0023] (1) After mixing simethicone and silicon dioxide, place it in an oven at 170°C for 4 hours at a constant temperature, take it out and cool to room temperature to obtain a simethicone-silica compound for use;

[0024] (2) Sodium carboxymethyl cellulose is dispersed in 500ml of water to make a uniform solution for later use;

[0025] (3) Dissolve 2,6-di-tert-butyl-p-cresol in ethanol to make a uniform ethanol solution for later use;

[0026] (4) Mix polysorbate and Span evenly to make a mixed emulsifier, set aside;

[0027] (5) Sodium saccharin, fresh milk essence, and ethyl paraben are dissolved in 100ml of water to make a uniform solution for later use;

[0028] (6) Mix simethicone silica compound and mixed emulsifier at 75°C, add 200ml of 75°C water, homogenize in a homogenizer for 3 minutes, homogenize at a speed of 10000r / min, then stir, cool, and stir at a speed of 20r / min;

[0029] (7) In step 6...

Embodiment 2

[0032] 1. Prescription:

[0033]

[0034] 2. Process steps:

[0035] (1) After mixing simethicone and silicon dioxide, place it in an oven at 170°C for 6 hours at a constant temperature, take it out and cool to room temperature to obtain a simethicone-silica compound for use;

[0036] (2) Sodium carboxymethylcellulose is dispersed in 600ml of water to make a uniform solution for later use;

[0037] (3) Dissolve 2,6-di-tert-butyl-p-cresol in ethanol to make a uniform ethanol solution for later use;

[0038] (4) Mix polysorbate and Span evenly to make a mixed emulsifier, set aside;

[0039] (5) Sodium saccharin, fresh milk essence, and ethyl paraben are dissolved in 100ml of water to make a uniform solution for later use;

[0040] (6) Mix the simethicone silica compound and the mixed emulsifier at 80°C, add 150ml of 80°C water, homogenize in the homogenizer for 5 minutes, the homogenization speed is 7000r / min, then stir, cool, and the stirring speed is 30r / min;

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com