Ultrasonic reinforced hollow fiber membrane liquid-phase micro extraction technique and device

An extraction technology and extraction device technology, which are applied in the field of measuring liquid phase equilibrium parameters, can solve the problems of poor stability, high equipment requirements, complicated ultrasonic emulsification extraction operation process, etc., and achieve the effect of strong practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

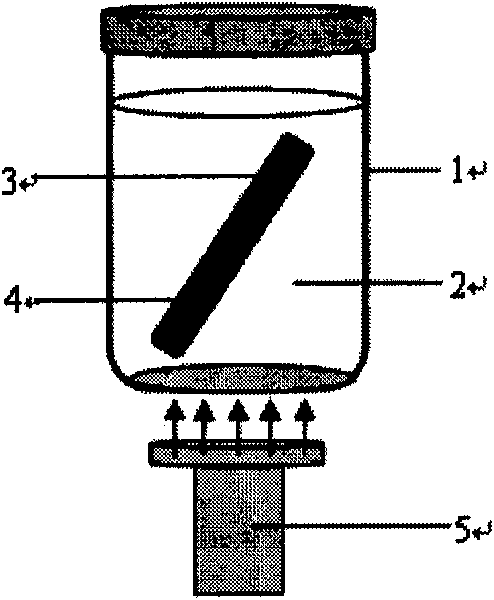

[0035] Example 1: Using nitrobenzene as a probe compound to test the impact of ultrasound on enrichment efficiency

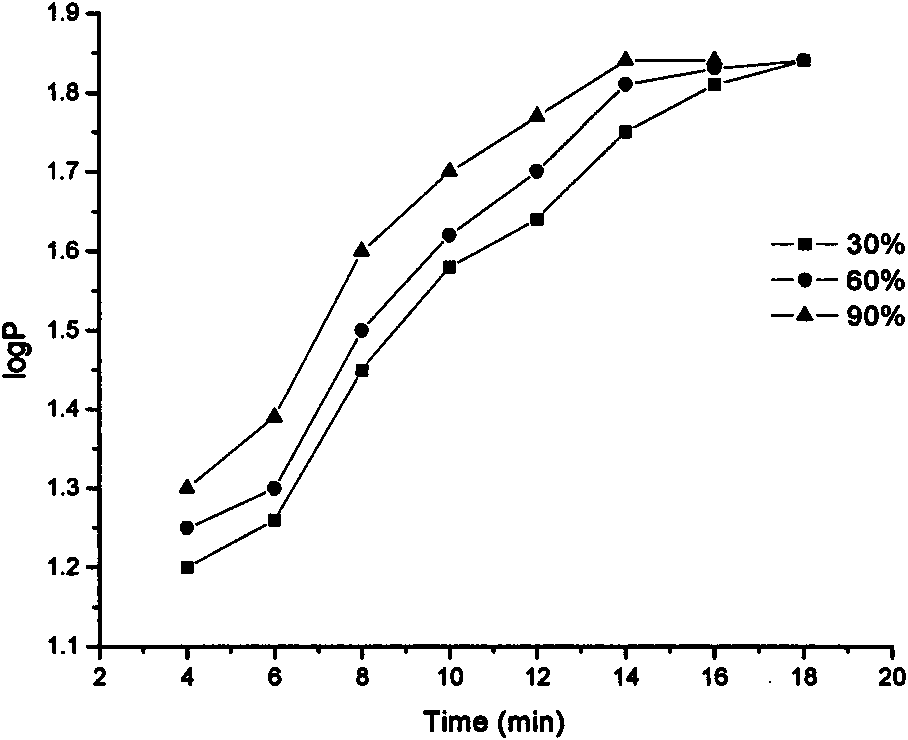

[0036] The membrane used is a hollow fiber membrane, the membrane pore size is 0.02 μm, the membrane porosity is 40%, and the inner diameter of the hollow membrane tube is 1 mm. Take n-octanol as the extraction phase, and nitrobenzene dilute aqueous solution as the sample solution. Take 50ml of sample solution in a small tubular container, place the hollow fiber membrane in n-octanol for a few seconds, add 25 μL of n-octanol to the membrane, seal both ends of the membrane and place it in a small tubular container, place the tubular A small container is placed directly above the sonicator probe. Turn on the power supply, complete the extraction under ultrasonic enhancement, take samples with a micro-injector, and measure the sample concentration of the extraction phase and the extraction residual phase in a gas chromatograph. figure 2 It is the influence of ul...

Embodiment 2

[0037] Example 2: Comparison of electric field enhanced mass transfer and extraction effect of traditional methods

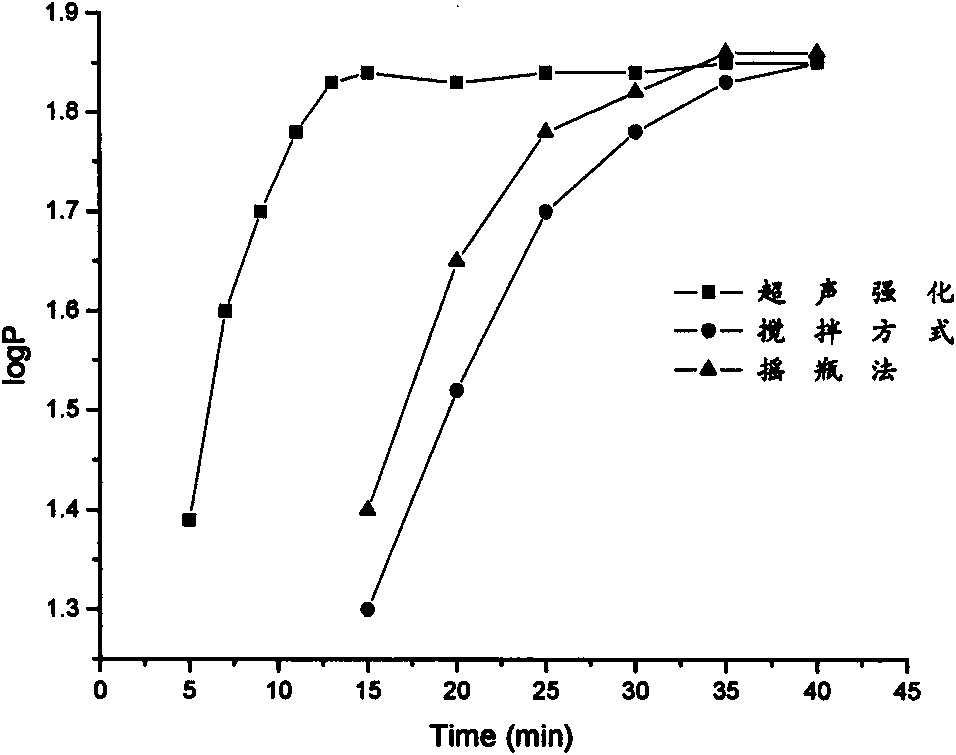

[0038]Using nitrobenzene as a probe compound to investigate the difference between the electric field enhanced mass transfer and the extraction effect of the traditional stirring method, the specific operation is the same as in Example 2, except that the first group of three groups of comparative experiments applies ultrasonic enhancement with a frequency of 40kHz and a power of 180W; The first group did not apply ultrasonic enhancement, but adopted the traditional shaking flask method; the third group did not apply ultrasonic enhancement, but instead applied magnetic stirring for strengthening. image 3 It is the effect of ultrasonic enhancement on the extraction effect. The experimental results show that the logP values measured by the three methods are the same, but the equilibrium time is 15min, 40min and 35min respectively. The fast and efficient characte...

Embodiment 3

[0039] Embodiment 3: Measure the logP of pure organic compound with this device

[0040] Aniline, nitrobenzene, and toluene were respectively taken as probe compounds, and the n-octanol-water partition coefficients of these pure substances were determined. The operation method is the same as in Example 1, the ultrasonic frequency is 40kHz, the power is 180W, and after extraction for 15min, the concentration of the analyte in the n-octanol phase and the water phase are measured respectively. The calculated n-octanol phase concentration / water phase concentration is the partition coefficient, and the logarithm of the partition coefficient is log P. Use this device to measure the log P of several compounds, see the table below:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com