Device and method for filling catalyst on line by pneumatic transmission

A pneumatic conveying and filling device technology, which is applied in the direction of conveying bulk materials, chemical instruments and methods, conveyors, etc., can solve the problems of large volume of flushing liquid, pipeline wear, and the inability to effectively control the solid content of conveying slurry, etc. , to achieve the effect of stable conveying and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

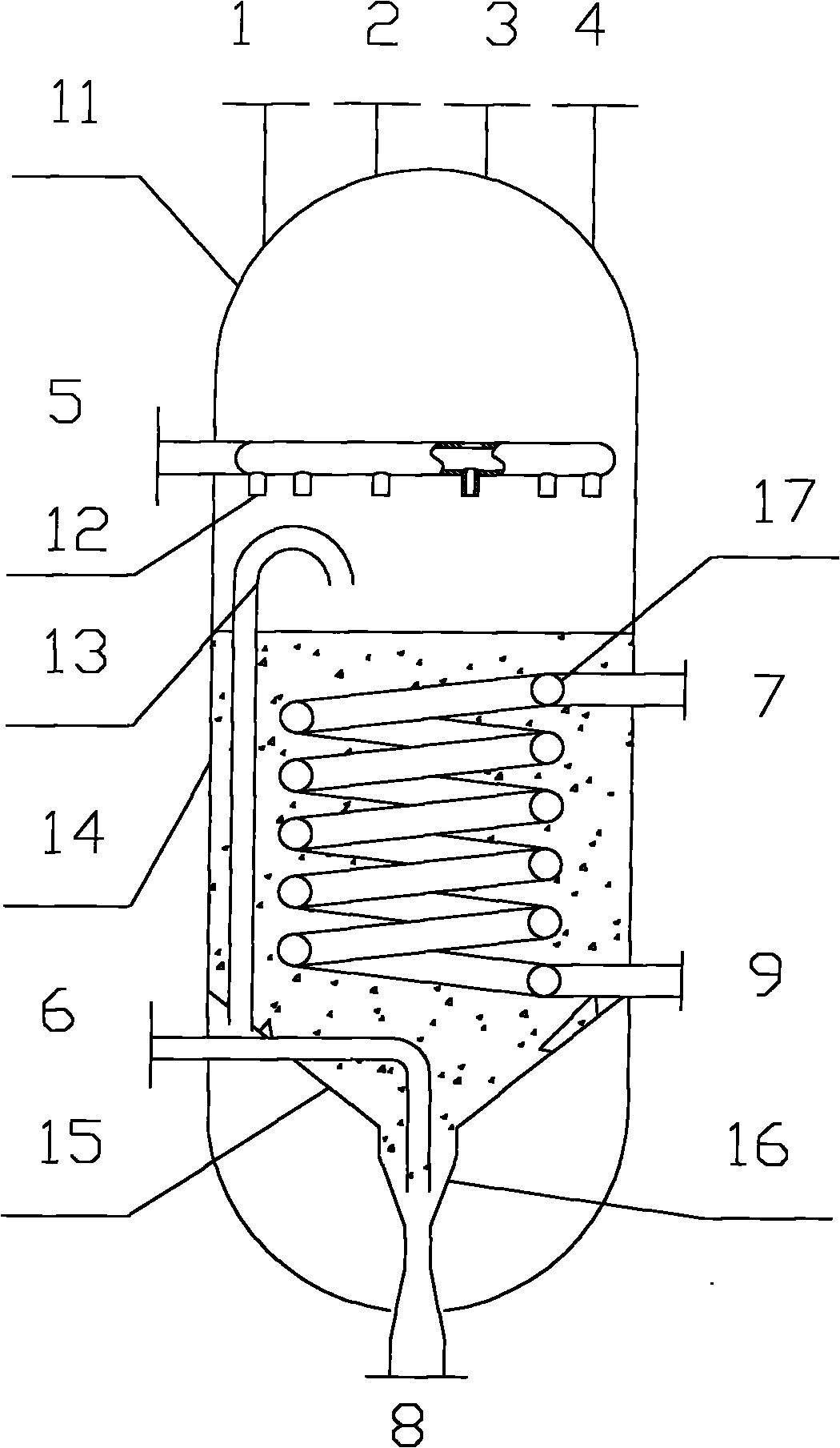

[0017] The online catalyst filling device of the present invention can use high-pressure hydrogen as the transmission power source to realize online filling of the catalyst. According to the catalyst online filling process provided by the present invention, it consists of four steps: catalyst dosing, gas replacement, catalyst preheating and catalyst filling; at the same time as catalyst dosing, nitrogen is injected to separate catalyst dust; Reactor gas phase product.

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

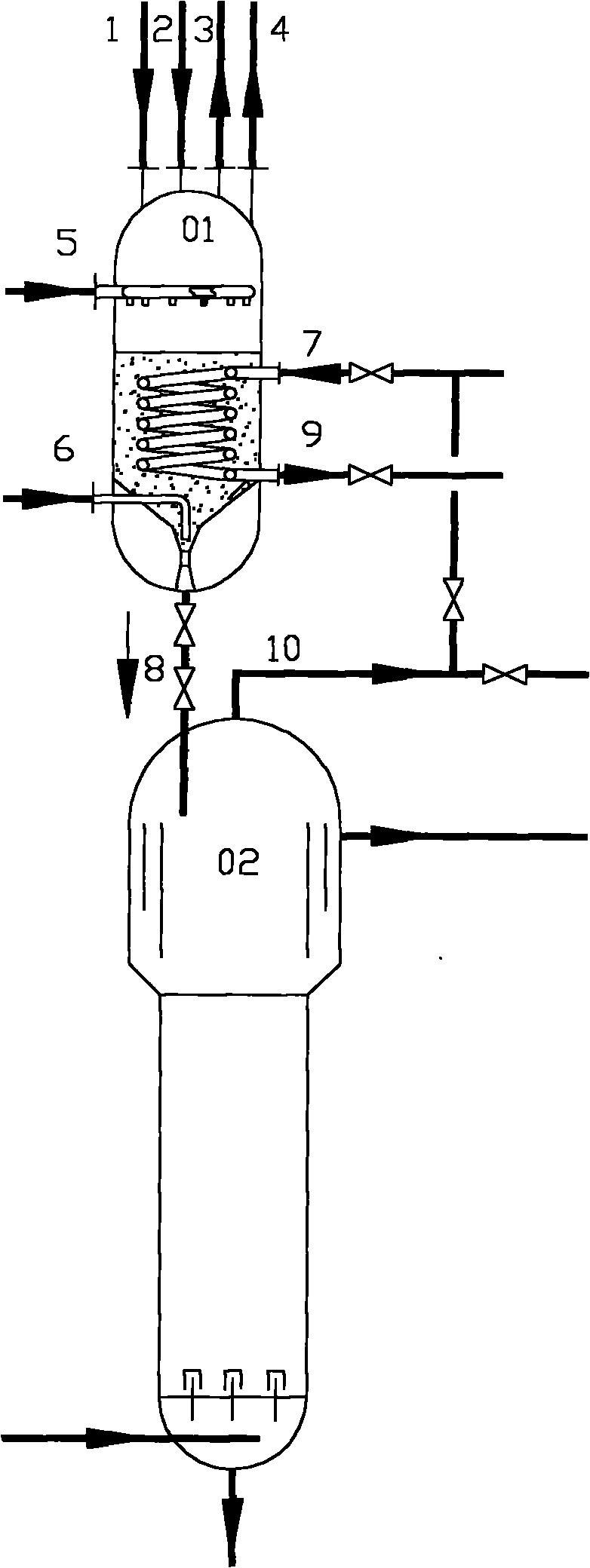

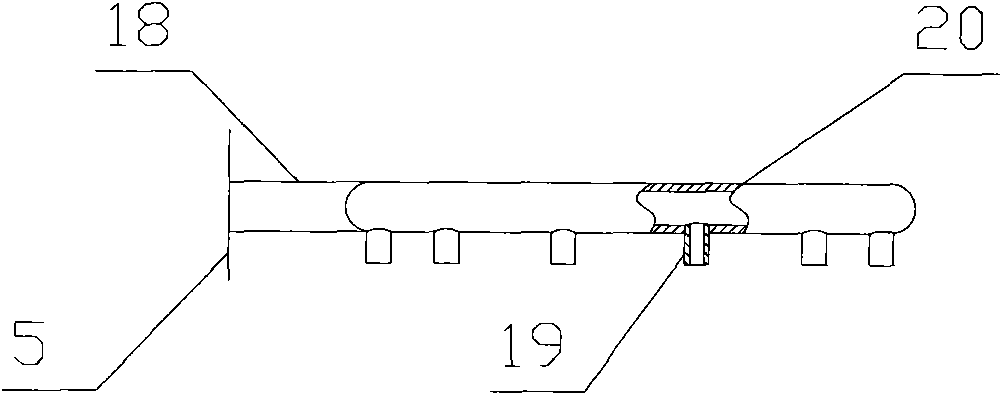

[0019] Such as figure 1 As shown, the online catalyst filling device of the present invention includes a catalyst filling tank 01, and the catalyst filling tank 01 and the ebullated bed reactor 02 are arranged up and down. The catalyst outlet 8 of the catalyst filling tank is connected to the top nozzle of the ebullated bed reactor through the process pipeline; the heat medium inlet 7 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com