Target and process for utilizing same to plate film on aluminum or aluminum alloy substrate

A technology based on an aluminum alloy base and a process method is applied in the field of target materials and the use of target materials to coat aluminum or aluminum alloy substrates. The effect of poor adhesion of the paint film and solving the problem of high pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

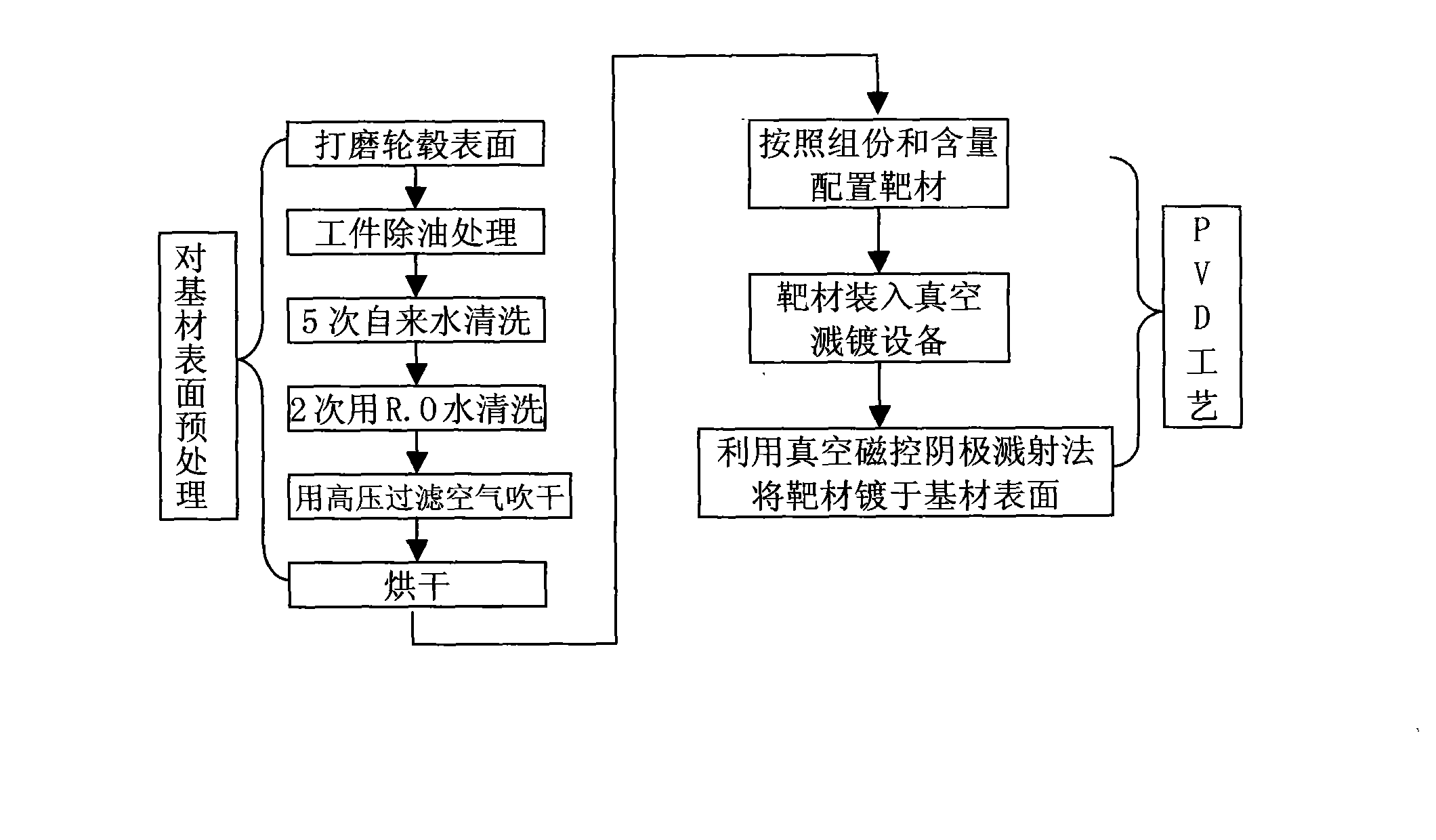

[0028] Combined with Figure 1, the following is a detailed description:

[0029] Utilize the process method of target material application on the automobile hub (base material) coating, its implementation steps are as follows:

[0030] The first step is to pre-treat the surface of the substrate

[0031] 1) Grind the surface of the wheel hub to make it smooth. During the grinding process of the workpiece, first use No. 240 coarse sandpaper for partial preliminary grinding, and then use No. 400 fine sandpaper to carefully polish and repair it to make the surface of the workpiece smooth and free of unevenness;

[0032] 2) Degreasing the hub workpiece;

[0033] 3) Wash with tap water 5 times;

[0034] 4) Rinse with R.O water twice;

[0035] 5) Blow dry with high-pressure filtered air;

[0036] 6) drying;

[0037] The second step, PVD process

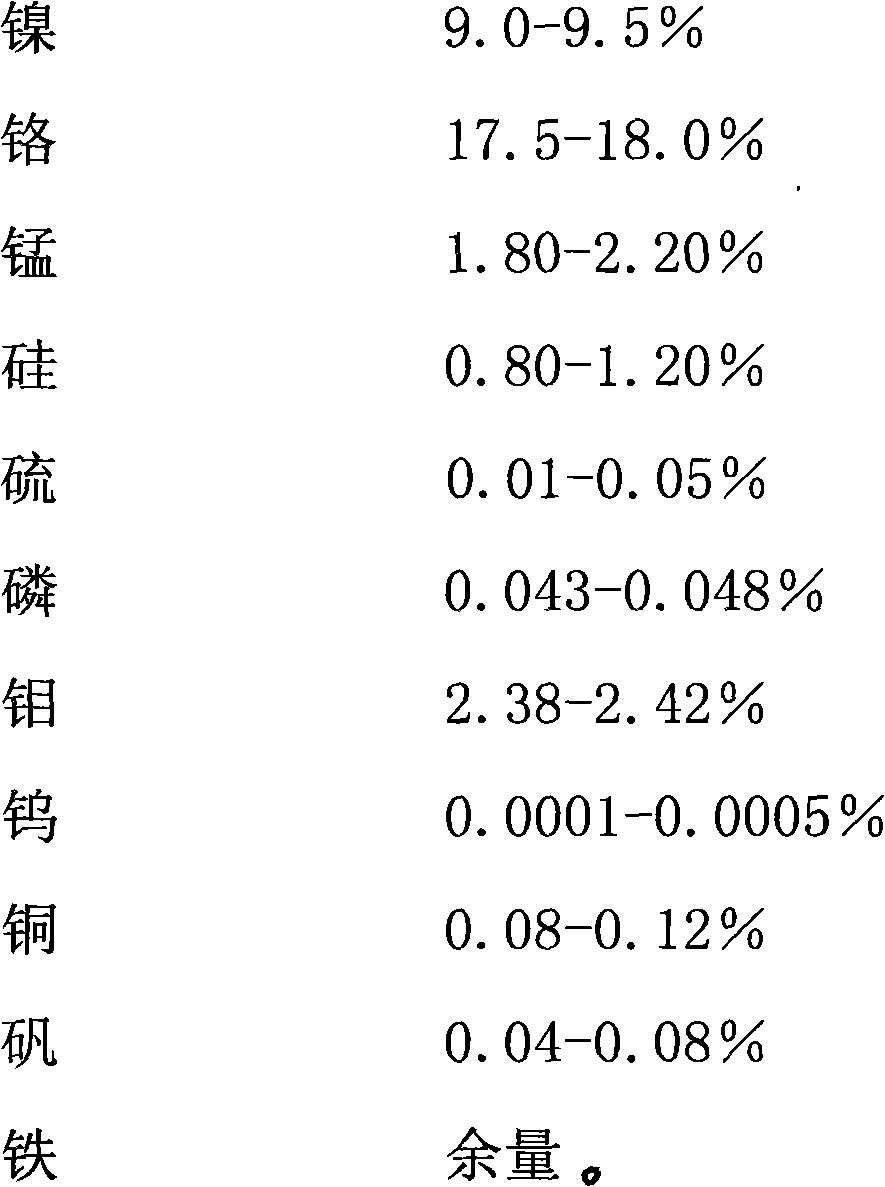

[0038] 1) Configure the required target according to the following components and weight content:

[0039]

[0040]

[0041] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com