Method for preparing giant field induced strain barium titanate single crystal

A technology of field-induced strain and barium titanate, applied in the field of preparation of giant field-induced strain barium titanate single crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

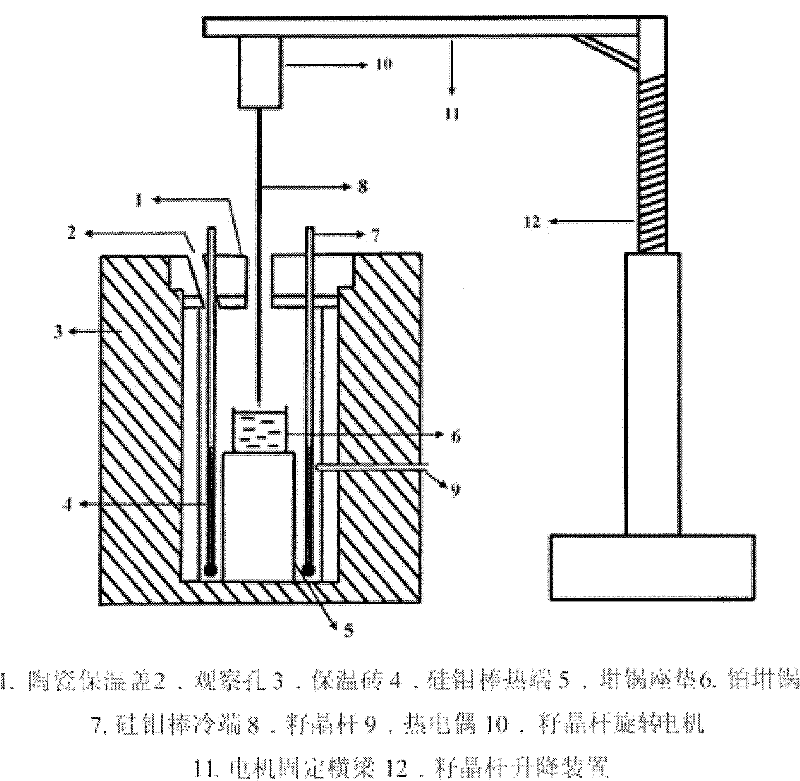

[0011] The top seed solution method (TSSG) is used to grow barium titanate single crystal, and the growth device is as follows figure 2 As shown, the growth atmosphere is atmospheric environment. The growth raw material is configured as barium carbonate with a purity of 99.99% and titanium dioxide with a purity of 99.99% mixed in a molar ratio of 35:30, and iron oxide with a doping amount of 200ppm is added at the same time. Put the configured raw materials into a platinum crucible, put them into a single crystal furnace, slowly raise the temperature to 1450°C to 1480°C, melt the raw materials, and then keep the temperature for more than 12 hours to fully dissolve the raw materials evenly.

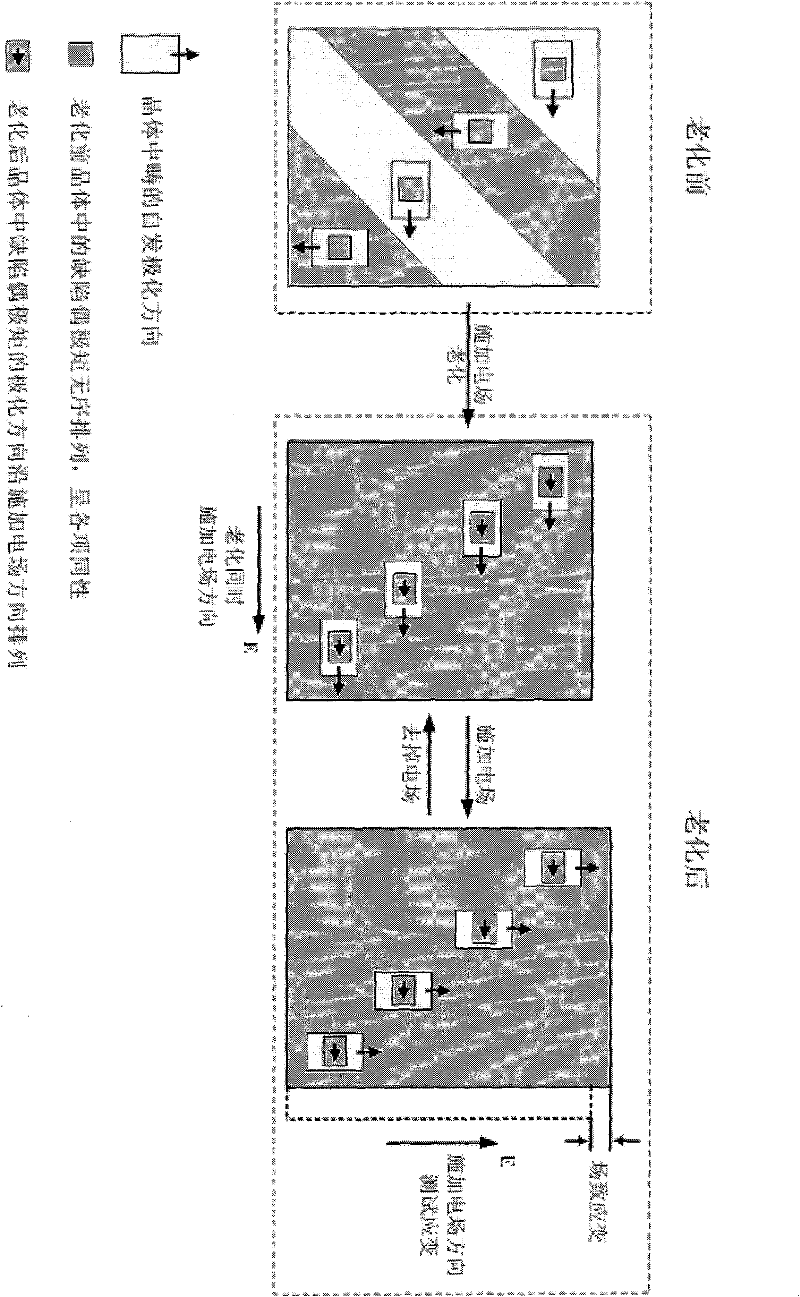

[0012] The barium titanate single crystal in the [001] direction is used as the seed crystal, and put into the fully melted solution to carry out the necking process first, so as to reduce the defects in the seed crystal continuing to the crystal, and then carry out shoulder expansion. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com