Cleaning system and cleaning method of developing solution circulation process equipment

A technology of cyclic treatment and cleaning system, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of ultrafiltration membrane damage, incomplete cleaning, small processing capacity, etc. The water flows back into the pump, the cleaning method is reasonable, and the effect of maintaining the filtering function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

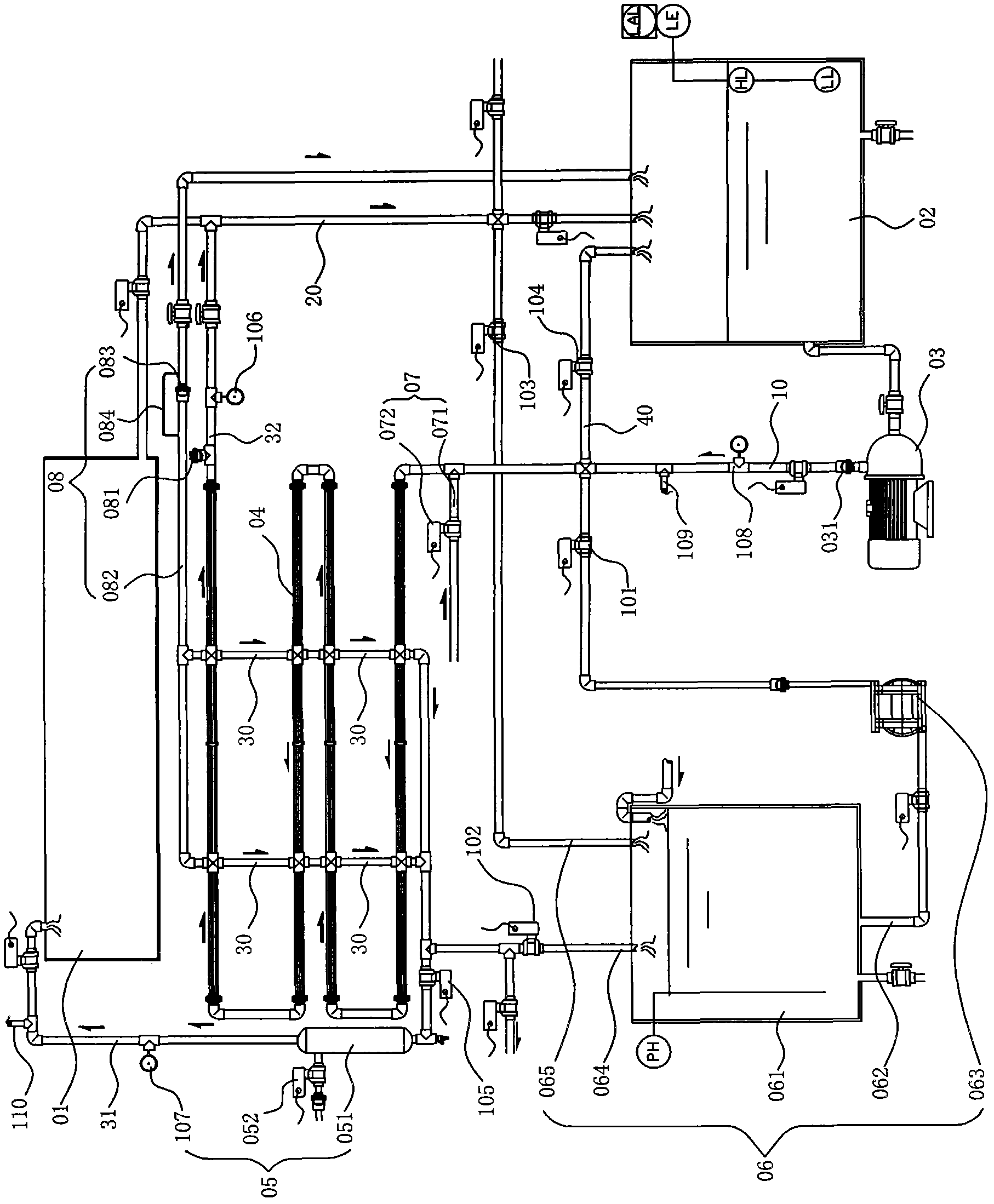

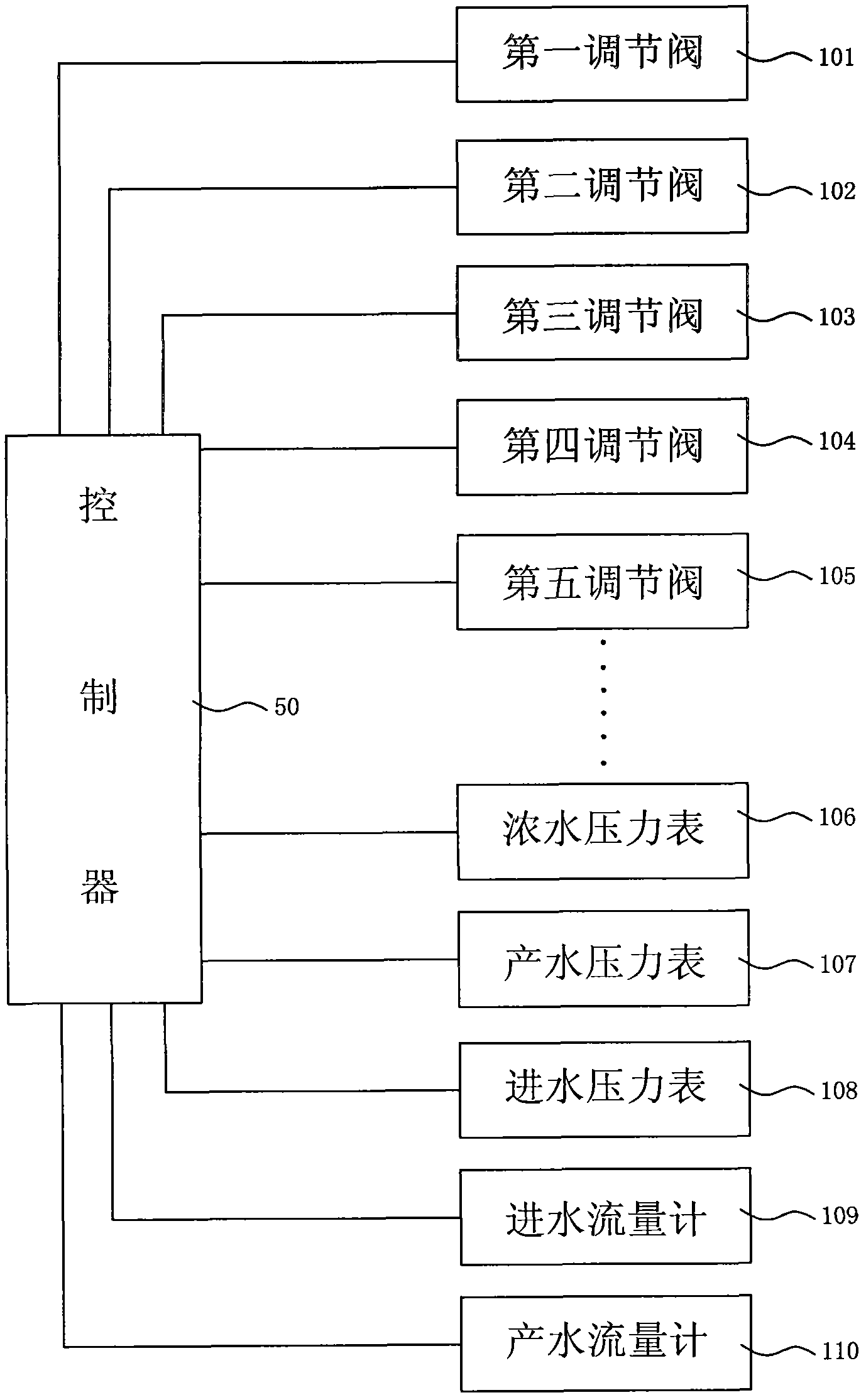

[0059] See figure 1 and figure 2 As shown, it shows the specific structure of a preferred embodiment of the present invention, a cleaning system and cleaning method of a developer circulation treatment equipment, including a developing tank 01, a concentration tank 02, a circulating power pump 03 and a cross-flow Filtered microfiltration membrane pipe fittings 04, wherein the developing tank 01 is connected to the concentration tank 02 in a pipeline type, and the concentration tank 02 is connected to the circulating power pump 03, and the circulating power pump 03 is connected to the microfiltration membrane pipe fittings through the pumping water pipeline 10 04, and the other end of the microfiltration membrane pipe fitting 04 is connected to the aforementioned concentration tank 02 through the concentrated water return pipeline 20, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com