Power line type field bus coal bunker continuous level detection device

A field bus, material level detection technology, applied in the direction of measuring device, lubrication indicating device, electrical program control, etc., can solve the problems of difficult system operation and maintenance, high one-time investment cost, strong electric interference on the system site, etc. The effect of engineering construction cycle, simple on-site wiring, and reduction in the number of program control cabinets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

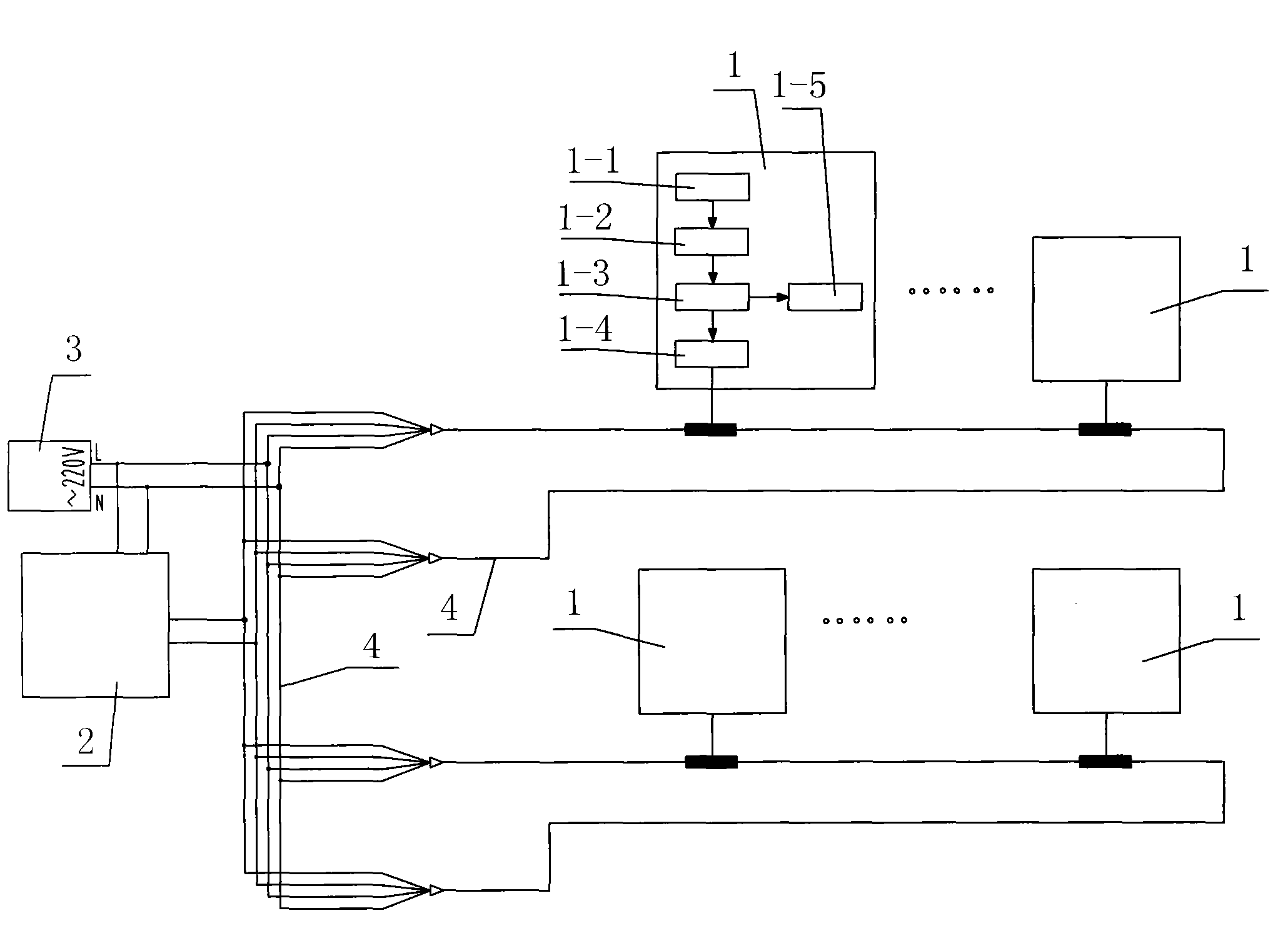

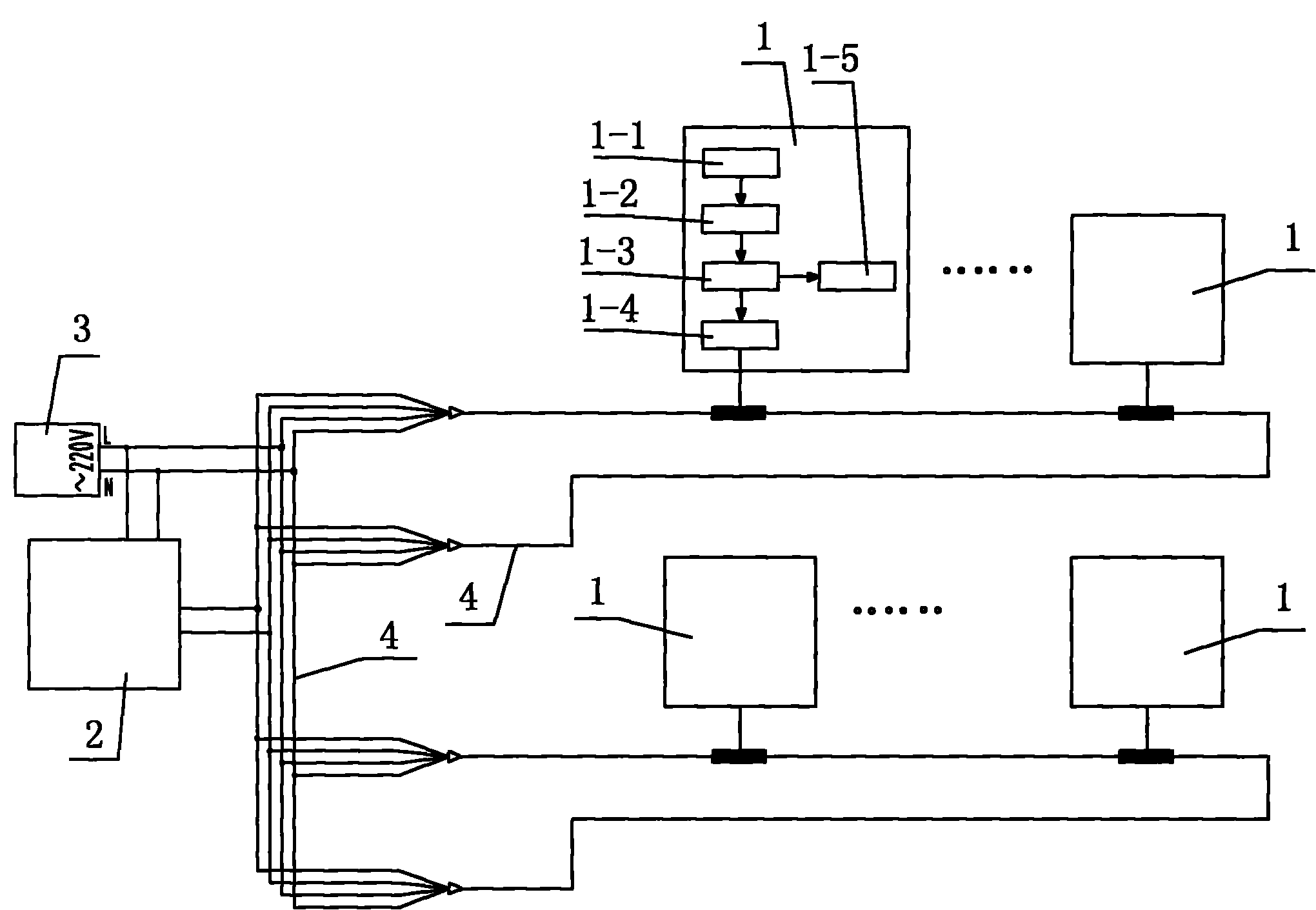

[0024] Such as figure 1 As shown, the present invention includes a plurality of continuous level gauges 1 and a power supply system 3 respectively connected to the plurality of continuous level gauges 1 . The material level gauge 1 includes an external housing, a material level sensor 1-1, an A / D converter 1-1 connected to the material level sensor 1-1 and performing analog-to-digital conversion on signals detected by the material level sensor 1-1 2. The MCU processor 1-3 connected with the A / D converter 1-2 and the I / O communication interface 1-4 connected with the MCU processor 1-3. The MCU processor 1-3 is connected with the main PLC control system 2 through the I / O communication interface 1-4 and the ring network formed by the cable 4, and each material level gauge 1 is connected in parallel to the main PLC through the ring network. On the control terminal of the PLC control system 2. In actual use, the main PLC control system 2 is connected to the DCS system by means of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com