Brushless double feed motor control device and direct torque control method thereof

A technology of direct torque control and double-fed motor, which is applied in the direction of AC motor control, control system, motor parameter estimation/correction, etc., to achieve the effect of simple implementation, improved control accuracy, and avoiding unstable observation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

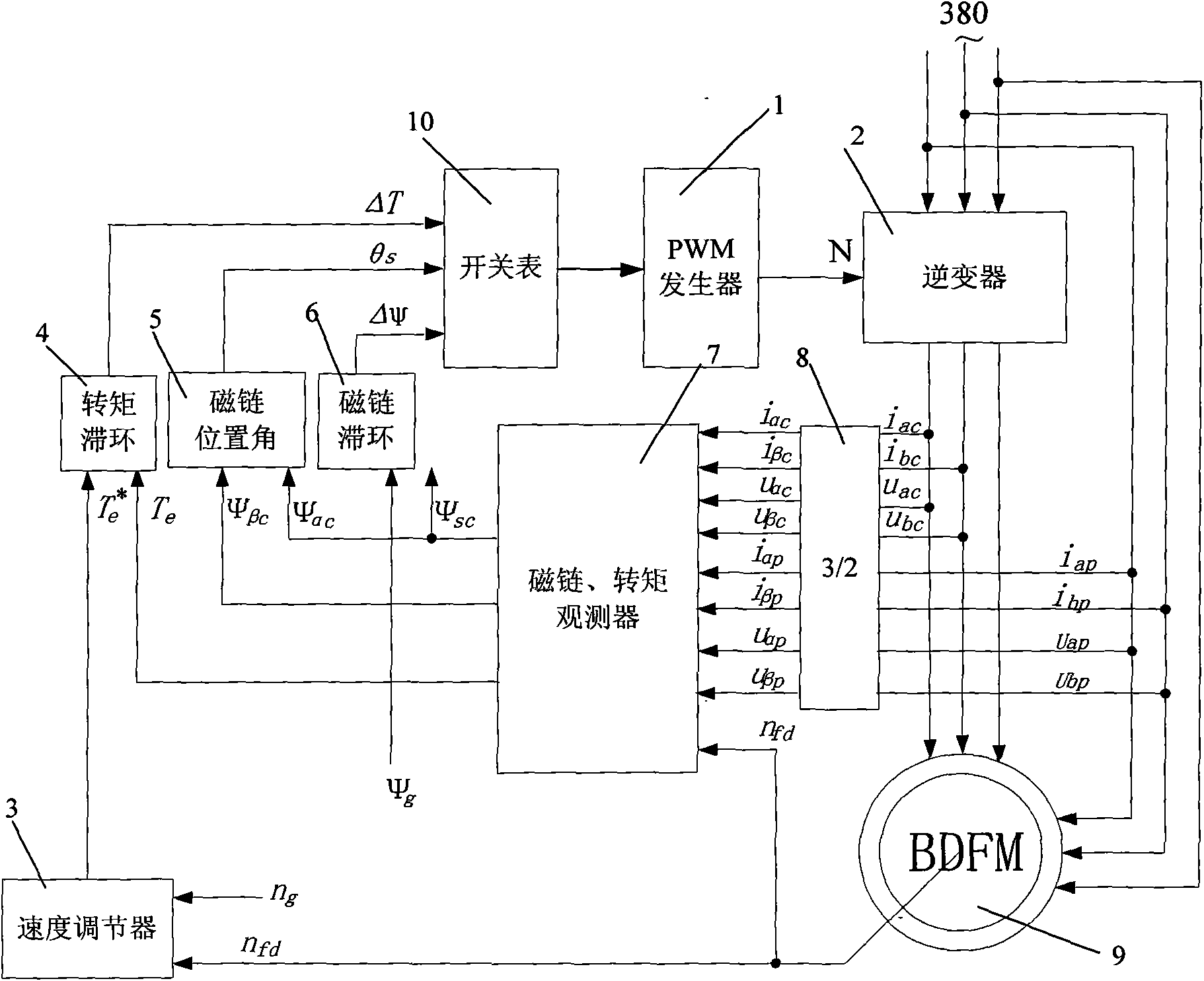

[0053] Such as figure 1 Realize that the brushless doubly-fed motor control device of the present invention is composed of a PWM generator 1, an inverter 2, a speed regulator 3, a torque hysteresis comparator 4, a flux linkage position angle calculation module 5, and a flux linkage hysteresis Ring comparator 6, flux linkage and torque observer 7, 3 / 2 converter 8, brushless doubly-fed motor 9 and switch meter module 10; wherein, the six output terminals of PWM generator 1 are respectively connected to inverter The six control terminals of the device 2, the output of the speed regulator 3 is connected to the input terminal of the torque hysteresis comparator 4, the signal output terminal of the 3 / 2 converter 8 is connected to the input terminal of the flux linkage and torque observer 7 , the output of the torque hysteresis comparator 4, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com