Soybean molasses fruit orange functional beverage and preparation method thereof

A technology of soybean molasses and fruit orange, which is applied in the field of functional beverages and its preparation, can solve the problems of soybean molasses waste and other problems, achieve pure and refreshing taste, high content of dietary fiber small molecule active substances, and facilitate absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

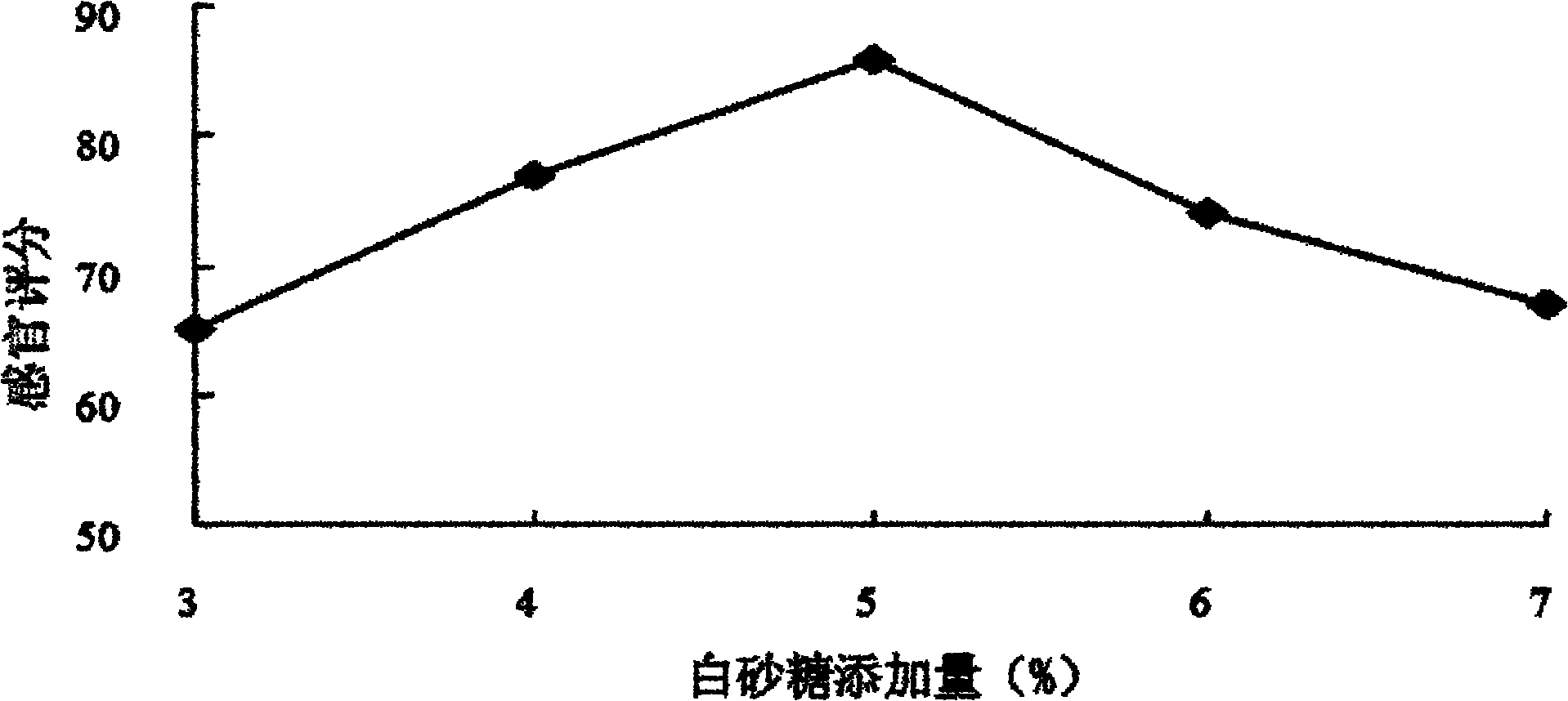

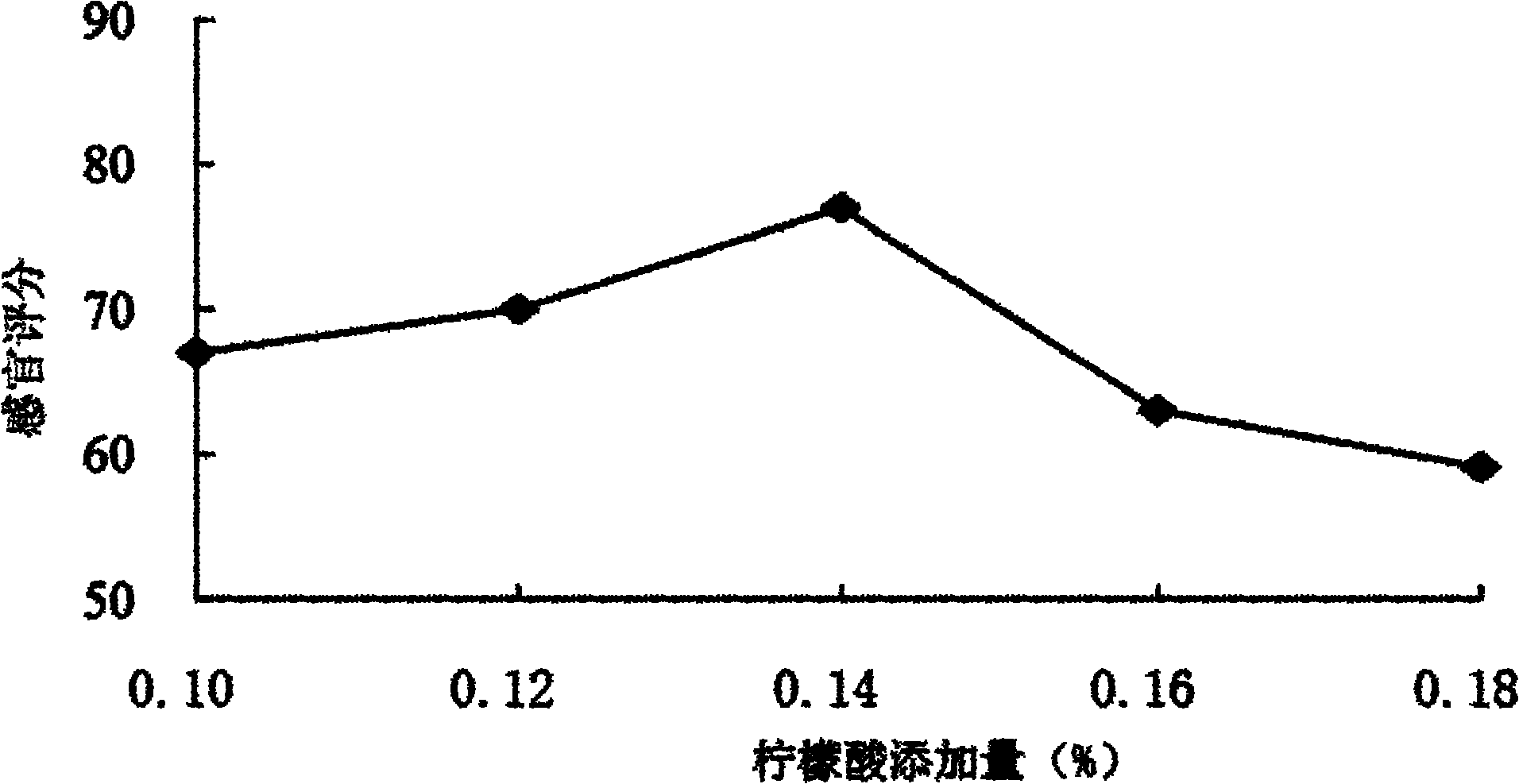

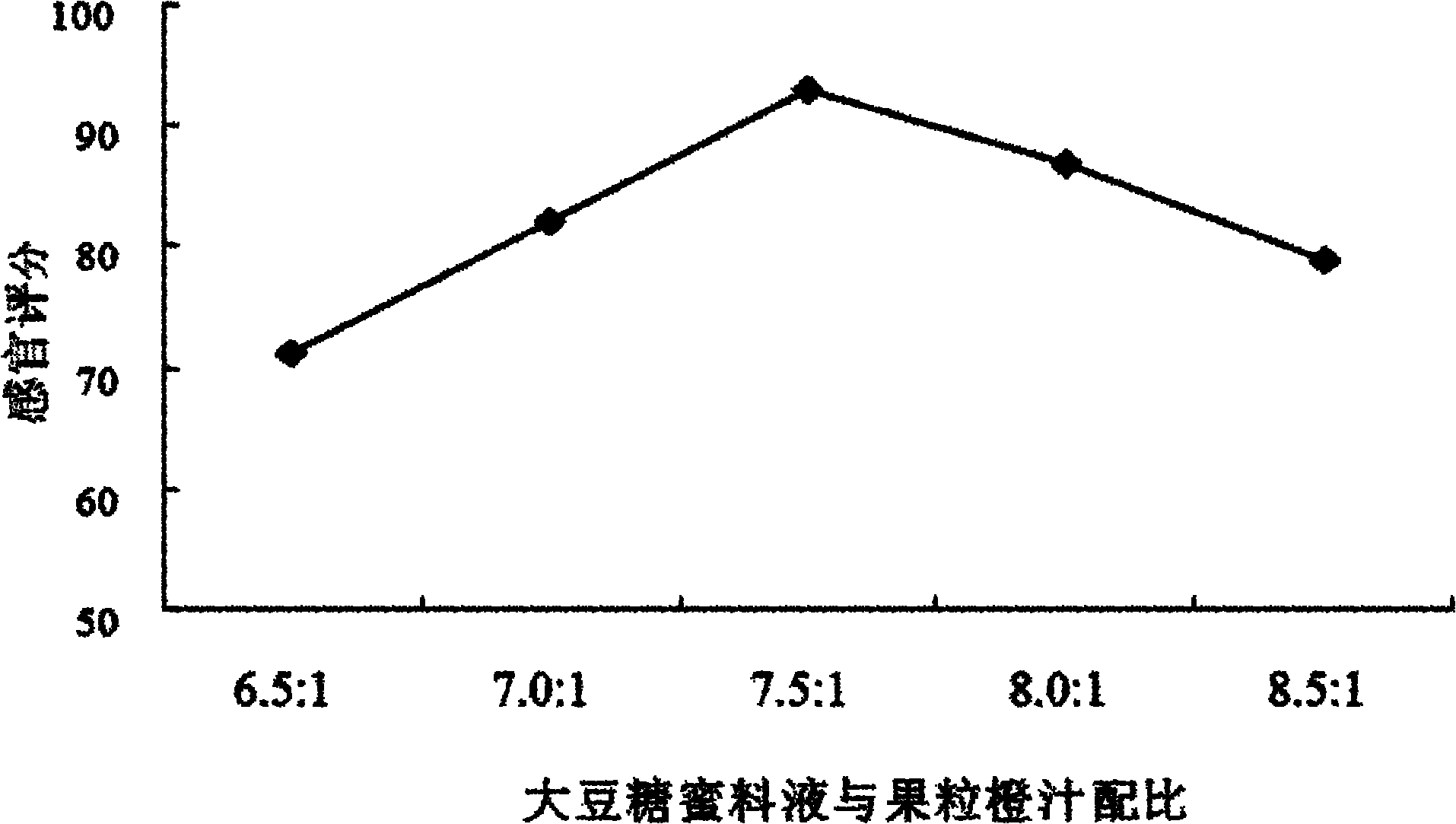

[0010] Specific embodiment one: in this embodiment, the soybean molasses fruit orange functional drink is composed of soybean molasses, water, fruit orange juice, white sugar, citric acid, sodium carboxymethyl cellulose, xanthan gum and sodium alginate; The mass ratio of soybean molasses, water and fruit orange juice is 3:12:2, the addition of white granulated sugar is 5% of the total mass of soybean molasses, water and fruit orange juice, and the addition of citric acid is soybean molasses, water and fruit orange juice. 0.12% of the total mass of orange juice, the addition of sodium carboxymethylcellulose is 0.10% of the total mass of soybean molasses, water and fruit orange juice, and the addition of xanthan gum is 0.10% of the total mass of soybean molasses, water and fruit orange juice 0.08%, the added amount of sodium alginate is 0.10% of the total mass of soybean molasses, water and fruit orange juice.

specific Embodiment approach 2

[0011] Specific embodiment two: the preparation method of soybean molasses orange functional drink in the present embodiment is as follows: 1. Pretreatment: it is 95 ℃~100 ℃ cooking pot that the citrus of fruit maturity is 95%~100% input temperature medium, soak for 30s to 60s, take out the skin, remove the network, dry, and then separate the orange petals; 2. Acid treatment: put the orange petals in hydrochloric acid with a temperature of 32°C to 35°C and a mass concentration of 0.5% to 1%. Soak in the solution, stir with compressed air for 25min to 30min, and then drain; 3. Alkali treatment: Put the orange petals treated in step 2 into hydrogen oxidization at a temperature of 25°C to 30°C and a mass concentration of 0.2% to 0.5%. Soak in sodium solution for 25min to 30min; 4. Rinse: Rinse the orange petals treated in step 3 with water at 10°C to 18°C for 30min to 35min; Put it into a juicer, stir and squeeze the juice, and then separate the fruit grains from the juice; 6. ...

specific Embodiment approach 3

[0065] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step two, the orange petals are soaked in a hydrochloric acid solution with a temperature of 34° C. and a mass concentration of 0.8%. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com