Diamond wire cutting apparatus and process of silicon wafer for solar cell

A technology of solar cells and cutting equipment, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve problems such as environmental pollution, low processing efficiency, large surface damage layer of silicon wafers, etc., to eliminate environmental pollution and improve The effect of processing quality and large output advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

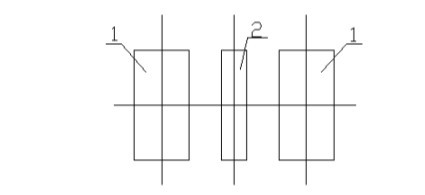

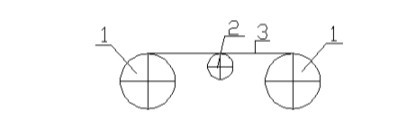

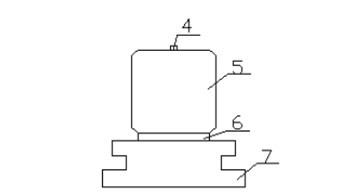

[0021] Such as Figure 1 to Figure 3 As shown in the diamond wire cutting equipment for silicon wafers for solar cells, the guide wheel part includes two main sheaves 1, and a small sheave 2 with a diameter smaller than the main sheave 1 is added between the two main sheaves 1, so that the small sheaves The outer diameter tangent of the upper end of the groove of the sheave 2 coincides with the outer diameter tangent of the upper end of the groove of the two main cutting sheaves 1, and they are installed at the same horizontal position. The shape is the same, the distance from the vertical line of the center of the small sheave 2 to the center of the two main sheaves is equal, and the small sheave 2 is used as a guide wheel for guiding the diamond steel wire passing through the two main cutting sheaves 1, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com