Method for producing sodium selenite

A technology of sodium selenite and its production method, applied in chemical instruments and methods, selenium/tellurium compounds, inorganic chemistry, etc., can solve problems such as environmental pollution and poisoning, serious equipment corrosion, long production cycle, etc., and achieve low production cost , small equipment investment and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

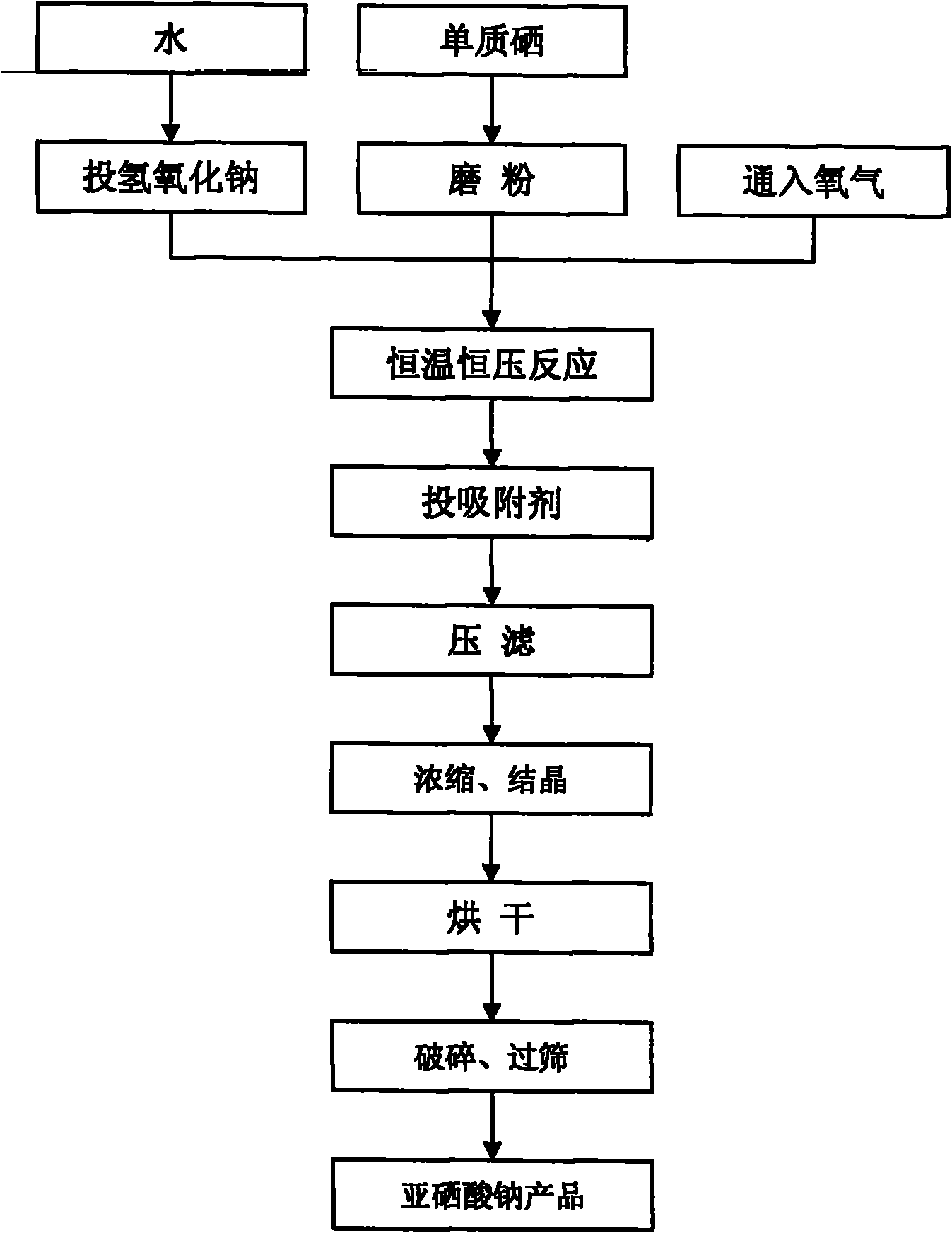

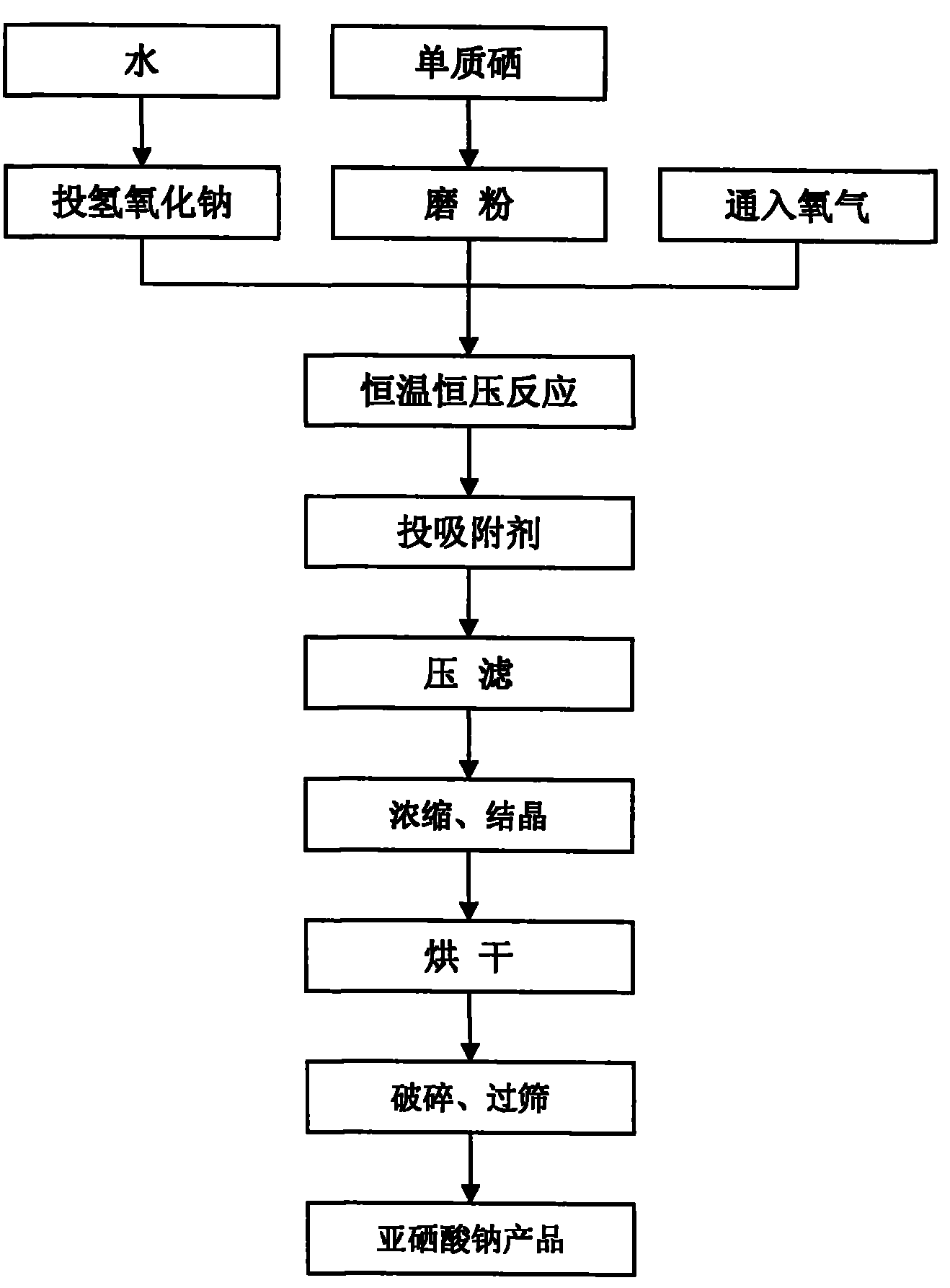

Method used

Image

Examples

Embodiment 1

[0027] A kind of sodium selenite production method, preparation process is as follows:

[0028] (1) Grinding elemental selenium into selenium powder by a mill and sieving;

[0029] (2) Water is added in the autoclave, open the reactor stirring paddle, then add solid sodium hydroxide by 152g / L in the kettle with a vacuum feeder to prepare aqueous sodium hydroxide solution (calculation method here is (150 / 78.9) × 2 × 40. Because the molar ratio of sodium hydroxide and selenium powder is 2: 1);

[0030] (3) Reactor is heated to 100 DEG C of insulation, and selenium powder is slowly dropped into reactor under agitation, and the control selenium concentration is 150g / L;

[0031] (4) Introduce high-pressure oxygen, and react at constant temperature and pressure for 10 hours at an oxygen pressure of 2.0 MPa and a temperature of 100° C.;

[0032] (5) Weigh 0.4kg of activated carbon adsorbent and add it to the reaction kettle, stir evenly, and cool down to ≤70°C after stirring for 2...

Embodiment 2

[0036] A kind of sodium selenite production method, preparation process is as follows:

[0037] (1) Grinding elemental selenium into selenium powder by a mill and sieving;

[0038] (2) water is added in the autoclave, open the reactor stirring paddle, then add solid sodium hydroxide by 202.8g / L in the kettle to prepare aqueous sodium hydroxide solution (calculation method is (200 / 78.9) ) × 2 × 40. Because the molar ratio of sodium hydroxide and selenium powder is 2: 1);

[0039] (3) Reactor is heated to 150 ℃ of insulation, and selenium powder is slowly dropped into the reactor under agitation, and the control selenium concentration is 200g / L;

[0040] (4) feed high-pressure oxygen, and react at constant temperature and pressure for 7 hours at an oxygen pressure of 1.5MPa and a temperature of 90°C;

[0041] (5) Weigh 1 kg of activated carbon adsorbent and add it to the reaction kettle, stir evenly, and cool down to ≤70°C after stirring for 3 hours;

[0042] (6) press filter...

Embodiment 3

[0045] A kind of sodium selenite production method, preparation process is as follows:

[0046] (1) Grinding elemental selenium into selenium powder by a mill and sieving;

[0047] (2) water is added in the autoclave, open the reactor stirring paddle, then add solid sodium hydroxide by 253.5g / L in the kettle with a vacuum feeder to prepare aqueous sodium hydroxide solution (calculation method here is (250 / 78.9) × 2 × 40. Because the mol ratio of sodium hydroxide and selenium powder is 2: 1);

[0048] (3) Reactor is heated to 200 ℃ insulation, selenium powder is slowly dropped into reactor under agitation, and the control selenium concentration is 250g / L;

[0049] (4) Feed high-pressure oxygen, and react at constant temperature and pressure for 14 hours at an oxygen pressure of 0.9MPa and a temperature of 140°C;

[0050] (5) Weigh 1.2kg of activated carbon adsorbent and add it to the reaction kettle, stir evenly, and cool down to ≤70°C after stirring for 5 hours;

[0051] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com