Low-odor polypropylene composite and preparation method thereof

A polypropylene composition and low-odor technology are applied in the field of low-odor polypropylene composition and its preparation, and achieve the effects of good mechanical properties, simple preparation process, and inhibition of polypropylene decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

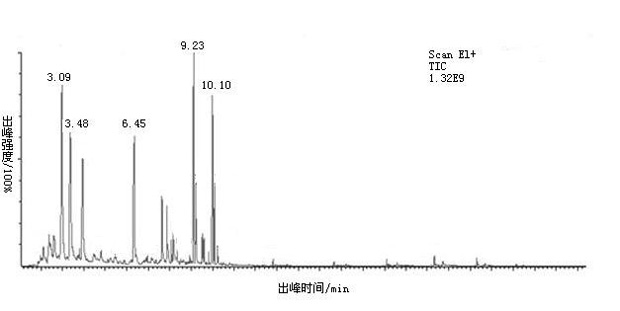

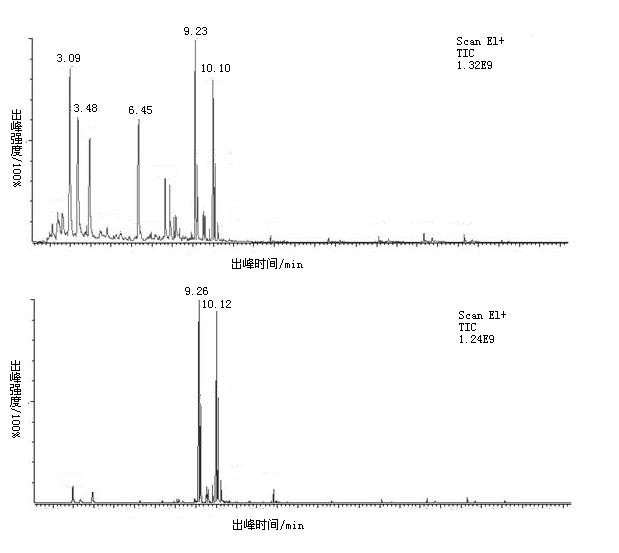

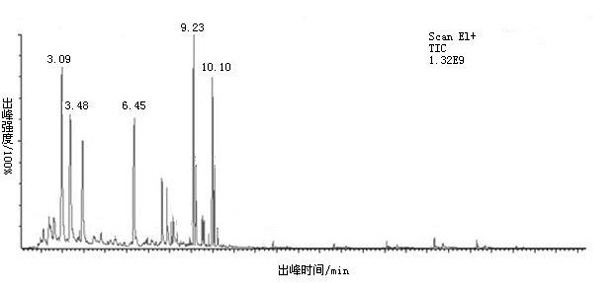

Image

Examples

preparation example Construction

[0065] The preparation method of the odor inhibitor: clay, zeolite, and metal oxides are activated in a muffle furnace at 500-600°C for 2 hours, taken out and placed in an odorless oven at 100°C to cool for later use.

[0066] For the same modified polypropylene formulation system, we prepared Comparative Examples 1-5 and Example 1 to investigate the ability of the odor control composition to absorb odor substances.

[0067] We investigated the change of odor by investigating the ratio and addition amount of different odor control compositions in Comparative Examples 6-8 and Example 2.

[0068] Since the types and contents of odor substances contained in different modified polypropylene formulation systems are different, we conduct investigations through Example 2 and Example 3.

[0069] Compared before and after adding the odor composition, although after adding suitable composition and suitable proportioning, the odor is obviously reduced, but it should be understood that th...

Embodiment 1

[0091] Table 6 formula content

[0092] components

Manufacturer

weight percentage

PP

Sinopec, Singapore Polyolefin

69%

POE

Mitsui

10%

talcum powder

Heshan Chemical Group

19%

odor suppressant

self made

1%

anti aging agent

Ciba

1%

[0093] In this scheme, the odor inhibitor is a clay and zeolite composition, and their weight percentages in the odor inhibitor are: clay 30%, zeolite 70%. Among them, SiO in clay 2 / Al 2 o 3 The molar ratio is 135, and the zeolite is a zeolite with a large surface area, and the specific surface area is 150~350m 2 / gr, the pore diameter is less than or equal to 1 nanometer, and the zeolite is a hydrophilic zeolite. The above raw materials were first put into a high-speed mixer with a rotation speed of about 1000 rpm and mixed for 3 minutes. See Comparative Example 1 for the extrusion granulation process.

[0094] The sample properties that comparative e...

Embodiment 2

[0113] Table 11 Formula content

[0114] components

Manufacturer

weight percentage

PP

Sinopec, Singapore Polyolefin

75%

POE

Mitsui

7%

talcum powder

Heshan Chemical Group

13%

odor suppressant

self made

4%

anti aging agent

Ciba

1%

[0115] In this solution, the odor inhibitor is clay, zeolite, and metal oxide composition, and their weight percentages in the odor inhibitor are: clay 25%, zeolite 50%, and metal oxide 25%, wherein the metal oxide is calcium oxide. Among them, SiO in clay 2 / Al 2 o 3 The ratio is 135, and the zeolite is a zeolite with a large surface area, and its specific surface area is 150~350m 2 / gr, the pore diameter is less than or equal to 1 nm. The above raw materials were first put into a high-speed mixer with a rotation speed of about 1000 rpm and mixed for 3 minutes. See Comparative Example 1 for the extrusion granulation process. The properties of Comparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com