Method for improving luminosity of europium-doped yttrium oxide red fluorescent powder

A technology of red fluorescent powder and luminous brightness, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of increased luminous intensity, mild reaction conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

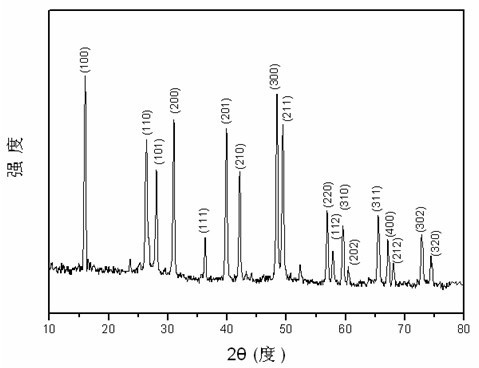

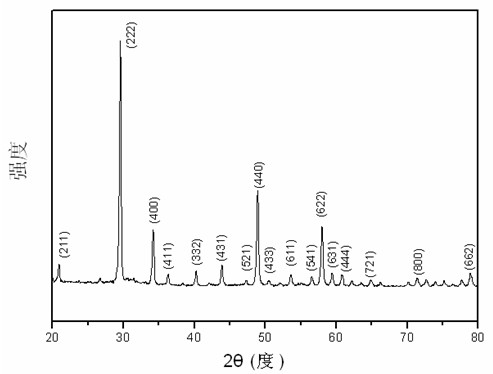

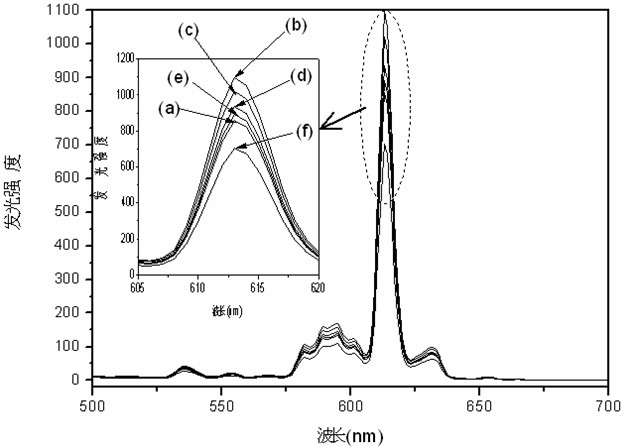

Image

Examples

Embodiment 1

[0020] Get 1.1642 grams of yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), 0.0714 grams of europium nitrate (Eu(NO 3 ) 3 ·6H 2 O) be dissolved in 40 milliliters of deionized water, the concentrations of yttrium nitrate and europium nitrate are respectively 0.0760 mol / liter and 0.0040 mol / liter, and stir. Add 32 milliliters of 1 mol / liter sodium hydroxide solution to the above solution, control the number of moles of sodium hydroxide to be 10 times of the total number of moles of rare earth cations, and stir. Put the above prepared solution into a polytetrafluoroethylene-lined autoclave with a filling degree of 80% and a liner volume of 100 milliliters. The solution was treated at 220°C for 24 hours, and the cooled solution was centrifuged to obtain a product with a molar concentration of europium doped at 5%. In the solid product that above-mentioned centrifugation obtains, add deionized water, stir, then 0.1225 gram of yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O) dissolved therein, th...

Embodiment 2

[0022] Get 1.1642 grams of yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), 0.0714 grams of europium nitrate (Eu(NO 3 ) 3 ·6H 2 (0) be dissolved in 40 milliliters of deionized water, the molar concentrations of yttrium nitrate and europium nitrate are respectively 0.0760 mol / liter, 0.0040 mol / liter, stir, add 32 milliliters of 1 mol / liter sodium hydroxide solutions in the above-mentioned solution, control The molar number of sodium hydroxide is 10 times of the total rare earth cation molar number, stirring. The stirred solution was put into a polytetrafluoroethylene-lined autoclave with a filling degree of 80% and a liner volume of 100 ml. The solution was treated at 220°C for 24 hours, the cooled solution was centrifuged and dried, and the doping concentration of europium accounted for 5% of the total moles of rare earth elements. In the solid product that above-mentioned centrifugation obtains, add deionized water, stir, then 0.1532 gram of yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O)...

Embodiment 3

[0024] Get 1.1642 grams of yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), 0.0714 grams of europium nitrate (Eu(NO 3 ) 3 ·6H 2 O) be dissolved in 40 milliliters of deionized water, the molar concentrations of yttrium nitrate and europium nitrate are respectively 0.0760 mol / liter and 0.0040 mol / liter, and stir. Add 32 milliliters of 1 mol / liter sodium hydroxide solution to the above solution, control the number of moles of sodium hydroxide to be 10 times of the total number of moles of rare earth cations, and stir. Put the above prepared solution into a polytetrafluoroethylene-lined autoclave with a filling degree of 80% and a liner volume of 100 milliliters. The solution was treated at 220°C for 24 hours, the cooled solution was centrifuged, and the doping concentration of europium accounted for 5% of the total moles of the total rare earth elements. In the solid product that above-mentioned centrifugation obtains, add deionized water, stir, then 0.2450 gram of yttrium nitrate (Y(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com