Hydrogenation treatment method for inferior feedstock oil

A technology for hydrotreating and raw materials, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of catalyst carbon deposition, unstable device operation, accelerated deactivation rate, etc., to improve light oil products. The effect of quality, full utilization, smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The properties of the residual oil raw materials used in the test are listed in Table 1. It can be seen from Table 1 that the residual carbon value of the residual oil raw material is 13.6wt%, and the metal content is 141.9 μg.g -1 , the asphaltene is 6.4wt%, the S content is 2.5wt%, and the N content is 0.6wt%, which is an inferior raw material that is difficult to process by conventional methods.

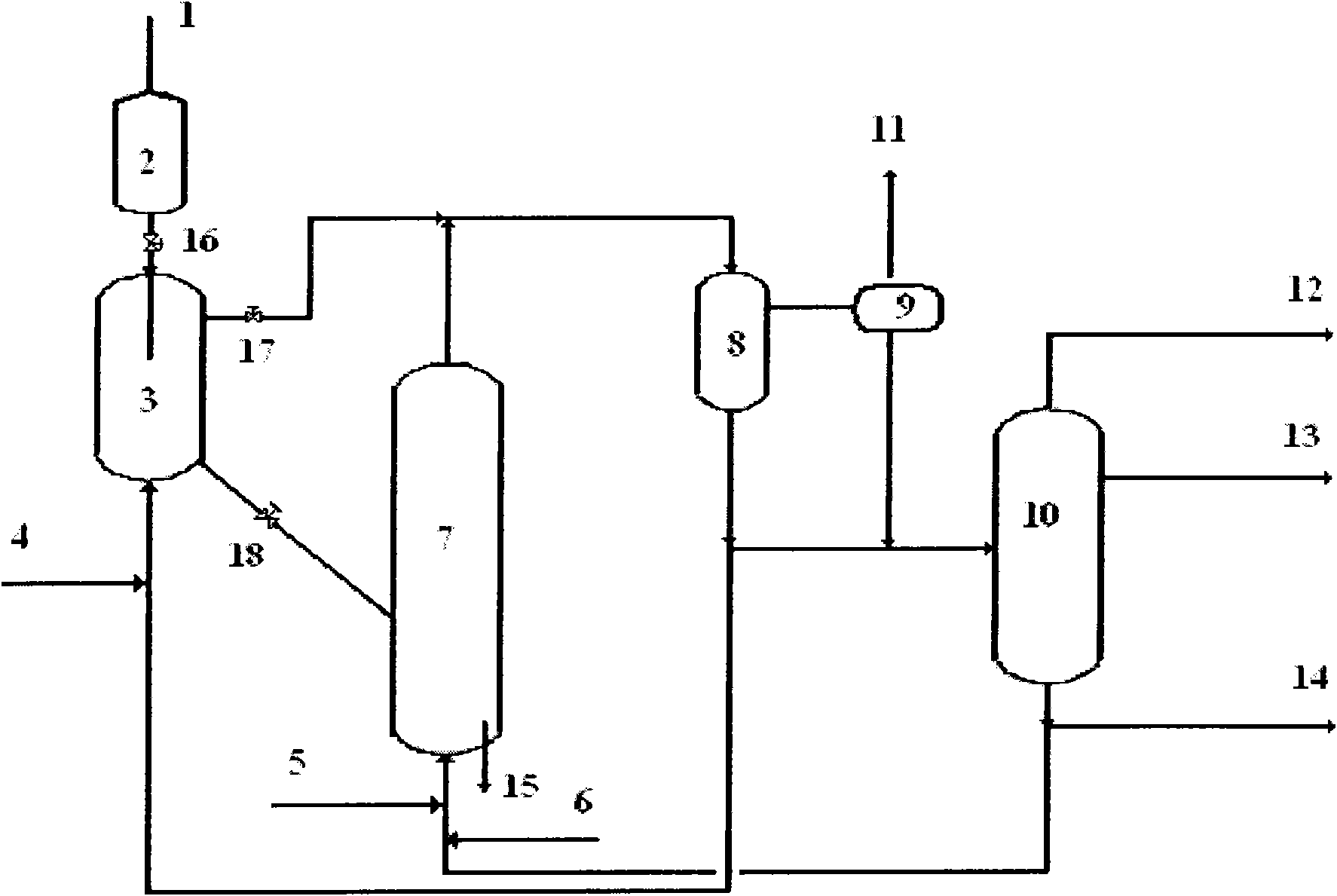

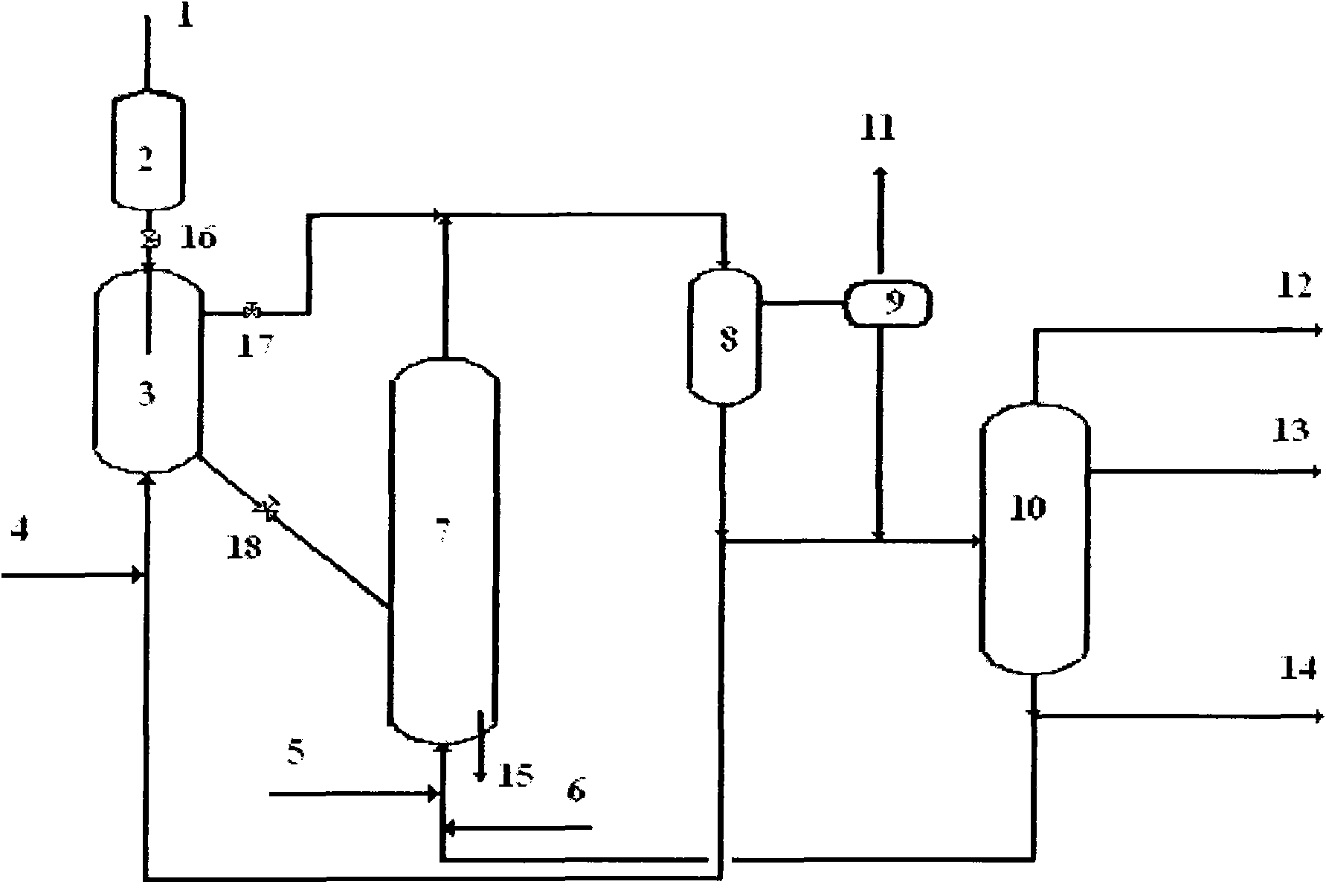

[0030] This example is an implementation scheme for the hydroprocessing of inferior raw materials, and the schematic diagram of the operation flow is referred to figure 1 .

[0031] The process is as follows: the heavy hydrocarbon raw material 6 and the hydrogen 5 are mixed and then enter the ebullating bed reactor 7 in an upflow mode to contact and react with the catalyst. After the ebullated bed hydrogenation reaction, the stream is discharged from the top of the reactor into the high-pressure separation device 8 for gas-liquid separation, and part of the separated liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com