Method for testing dynamic characteristics of lubricating film of sliding bearing

A sliding bearing and lubricating film technology is applied in the field of electromagnetic loading excitation devices, which can solve the problems of large error in parameter identification results, difficult to eliminate instrument phase errors, and high frequency of frequency terms, so as to broaden the three-dimensional physical meaning and engineering application value. , Reduce the test error and instrument phase error, the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

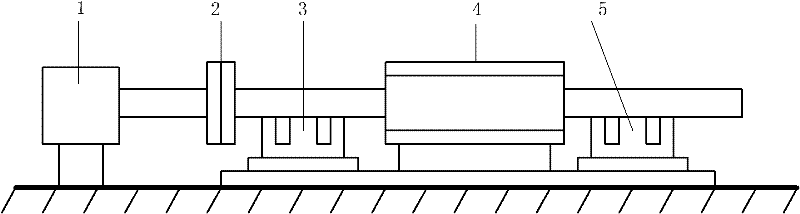

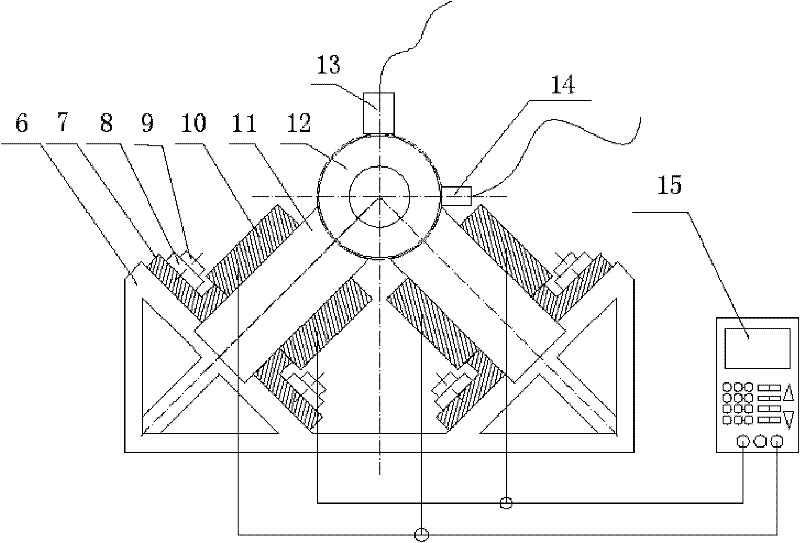

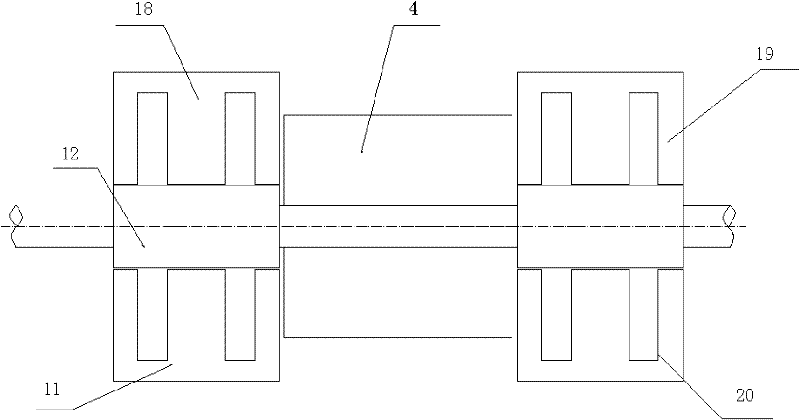

[0020] see Figure 1-4 , first, assemble the test bench ( figure 1 ), install pressure sensor, eddy current sensor, control power supply and water lubricant supply system. Set the spindle speed, lubricant temperature, and flow rate, and supply water lubricating medium from the lubricant inlet. Turn on the motor to drive the main shaft to rotate, and the lubricating medium forms a water lubricating film between the water-lubricated rubber bearing and the main shaft. Turn on the signal acquisition instrument and set the signal acquisition parameters. Then on the electromagnetic loading device (such as figure 2 ), the power supply control voltage is 0-40V, the resistance is 15 ohms, the diameter of the copper coil is 1mm, and the number of turns is 1585 turns; the length, width and height of the E-shaped electromagnet are 200mm, 60mm, and 110mm respectively; For the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com