Optical fiber sensing head with nano grid structure

An optical fiber sensing head and nanogrid technology, applied in the field of optical fiber sensing heads, can solve the problems of affecting resonance peaks, low excitation efficiency, bulky sensing device, etc., and achieve increased scattering cross-section, high sensitivity, localization Field enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

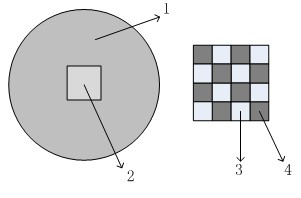

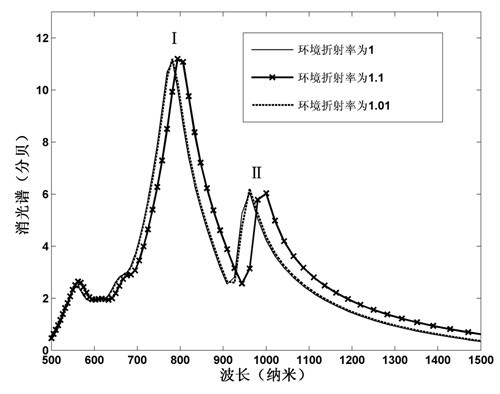

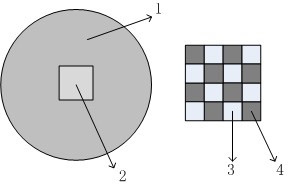

[0016] Such as figure 1 As shown, the optical fiber sensing head of the present embodiment comprises cladding (1) and fiber core (2), and described cladding (1) is the cylinder that diameter is 126 μ m, and refractive index is 1.65, and described fiber core (2) The cross-section is rectangular, with a size of 6 μm×6 μm. It is formed by a plurality of two glass materials (3, 4) with refractive indices of 1.5 and 1.7 arranged alternately on the xy plane. The cross-sections of the glass materials (3, 4) are 200nm×200nm rectangle, so that the rectangular fiber core section is divided into a grid of 30×30 arrays. On one end section of the fiber core (2), all low-refractive index glass material (3) end faces are etched to a depth of 10 nm along the axial direction z, while the unetched high-refractive index material (4) is etched away along the axial direction z Z is plated with a rectangular Au film with a size of 200nm and a thickness of 60nm. The length of the entire sensor hea...

Embodiment 2

[0018] The optical fiber sensing head of this embodiment comprises a cladding (1) and a fiber core (2), the cladding (1) is a cylinder with a diameter of 126 μm and a refractive index of 1.67, and the cross section of the fiber core (2) is rectangular , with a size of 6 μm × 6 μm, formed by alternate arrangement of two glass materials (3, 4) with refractive indices of 1.51 and 1.74 respectively on the xy plane, and the cross-sections of the glass materials (3, 4) are all 200 nm × 200 nm , so that the rectangular core section is divided into a grid of 30×30 arrays. On one end section of the fiber core (2), all low-refractive index glass material (3) end faces are etched to a depth of 20 nm along the axial direction z, while the unetched high-refractive index material (4) is etched away along the axial direction z Z is coated with a rectangular Au film with a size of 200nm and a thickness of 50nm. The length of the entire sensor head in the axial z direction is 70 μm.

[0019]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com