Metal ultrafine wire, process for production of metal ultrafine wire, and mesh wire netting using metal ultrafine wire

A metal pole and metal mesh technology, applied in the field of extremely thin metal wires, can solve problems such as breakage, wire breakage, and uneven weaving, and achieve the effects of suppressing breakage, stabilizing the tension state, and simplifying inventory management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] The wire rods (Examples A1-A6) made of the six Co-based alloy materials shown in Table 1, which were produced by the vacuum double melting method, were repeatedly subjected to cold drawing and heat treatment, and the diameter was reduced to the wire diameter Afterwards, it is heat-treated at a temperature of 1150°C to obtain a soft thin wire as a material. The wire drawing described above was performed by a sliding type wet wire drawing using a diamond die. In this series of material processing stages, there were no major problems such as wire breakage and die scratches, and they were processed well at an intermediate processing rate of 70-98%, especially the alloy wires of samples A1-A4 were good. In addition, in the microscopic examination of its cross section, no special harmful inclusions and structural defects were found.

[0108] On the other hand, in Comparative Examples B1 to B3, SUS304, 304N, and 316 materials conventionally used as high-strength ultra-fine wir...

Embodiment 2

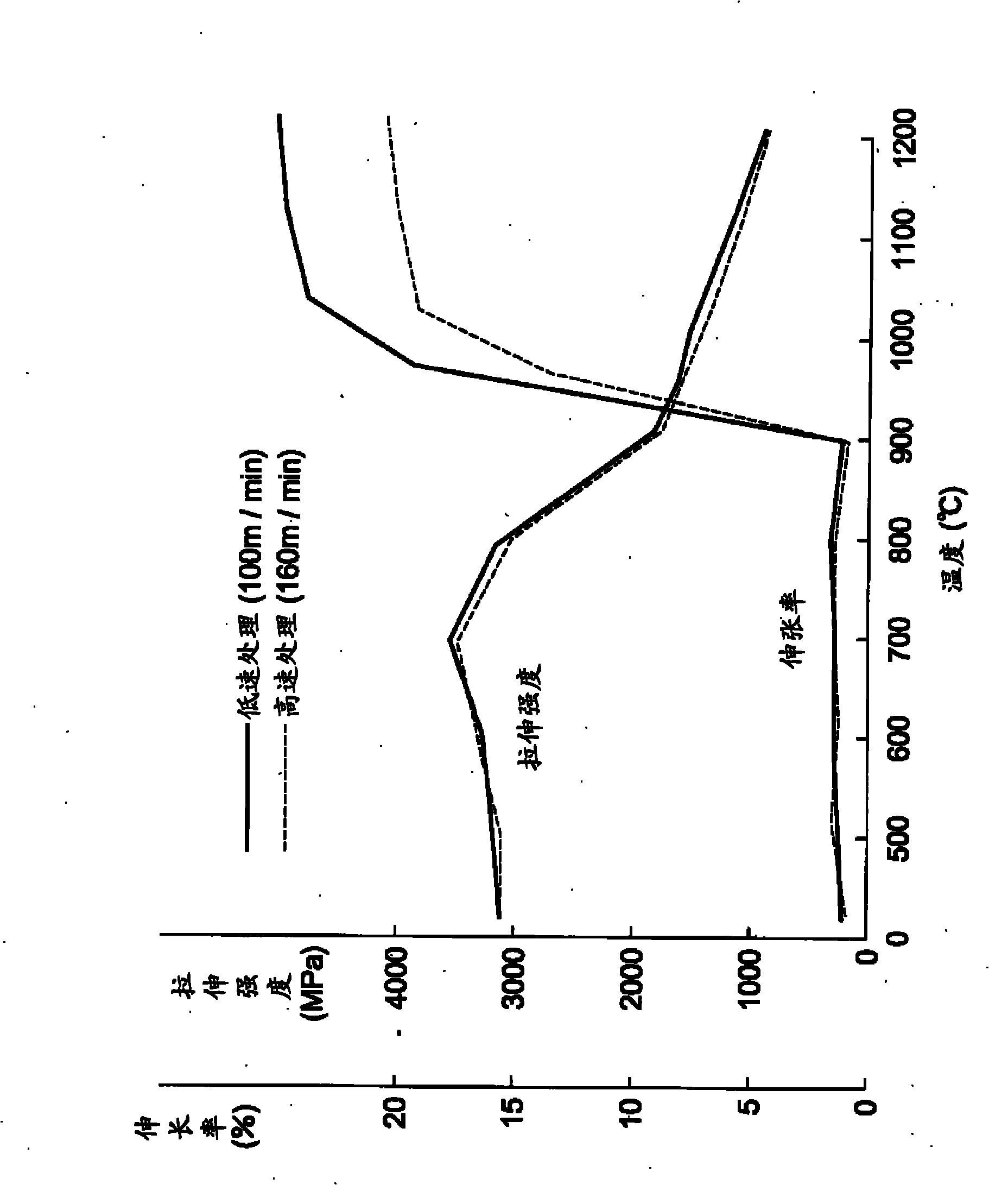

[0121] In above-mentioned embodiment A1, will be thinned into One end of the hard thin wire is annealed at a temperature of 1150°C to make a soft wire, and then drawn to 40 μm and annealed at a temperature of 1110°C, and the final cold drawing process is passed through the above-mentioned sliding type machine to reduce the diameter to 19 μm, and then heat treatment in the range of the above-mentioned B value of 120 to 130 to obtain the specified ultra-fine wire. As comparison objects, Comparative Examples B1 and B2 were used. Their processing ratios were lower than in Example A1, and were performed at 77%. In order to observe the influence at this time, the final heat treatment was similarly performed at a temperature of 1050° C.×100 m / min. The result is as Figure 5 shown.

Embodiment 3

[0124] In order to observe the influence of the ambient gas in the final heat treatment of Example A2 above on the characteristics, the same heat treatment was performed using Ar gas, and various characteristics were investigated. All the characteristics were within the range of the standard deviation, and no significant difference was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com