Oil gas absorption method

An absorption method, oil and gas technology, applied in separation methods, chemical instruments and methods, containers, etc., to achieve the effect of reducing water content, good absorption effect, and favorable for subsequent treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

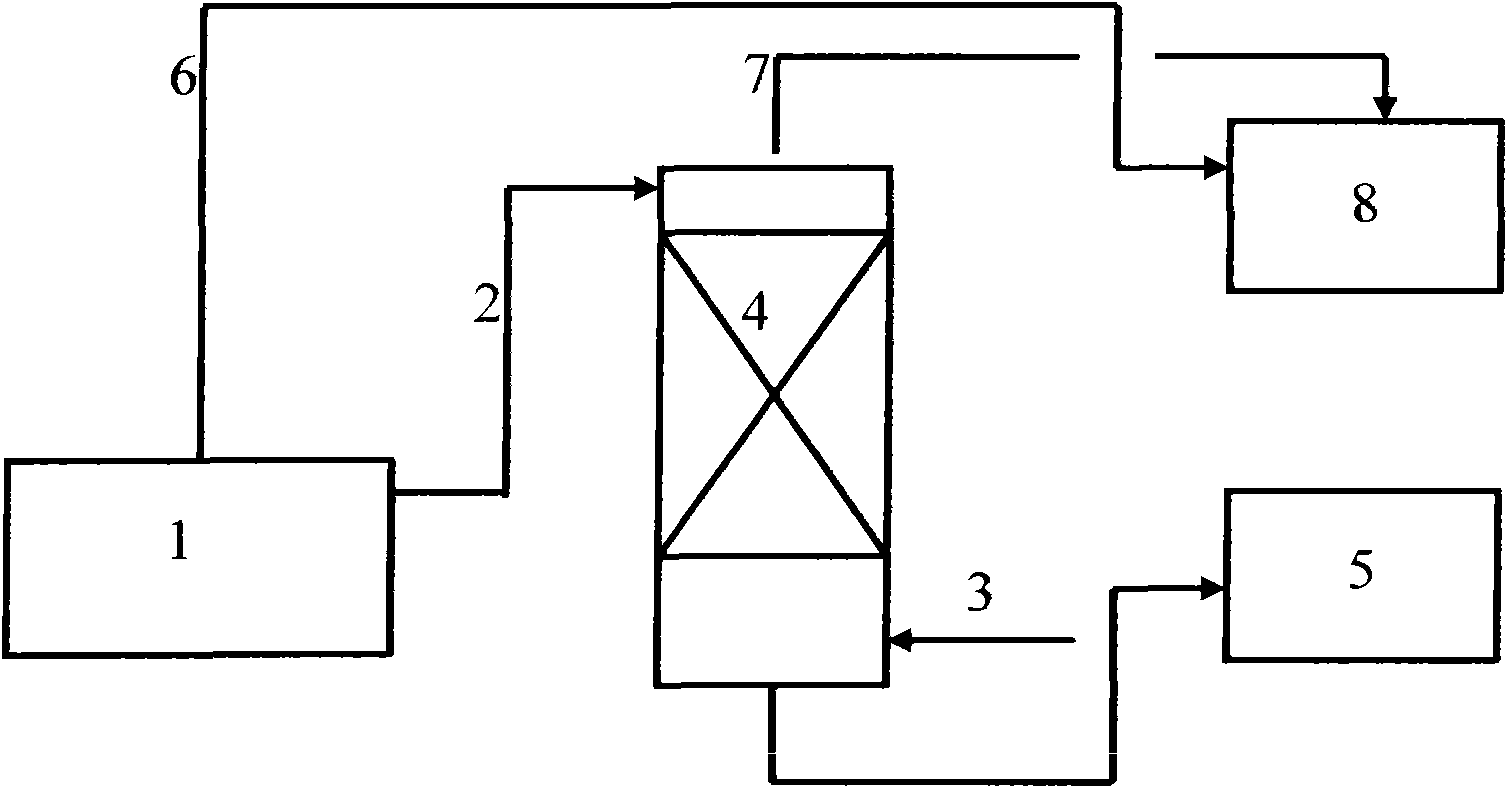

[0018] A gas oil storage tank area and a waste oil tank area discharge exhaust gas, the temperature is about 40°C, and the total oil gas concentration is 9×10 4 ~40×10 4 mg / m 3 , the sulfide concentration is 1000mg / m 3 about. First use sodium hydroxide solution to absorb and remove sulfide, after the sodium hydroxide solution absorbs, the sulfide concentration is lower than 10mg / m 3 , and then use the scum in the air flotation tank of the sewage treatment plant for absorption treatment.

[0019] The absorption treatment device adopts a packed tower, the packing is Φ25mm×25mm×2mm stainless steel Pall ring packing, the waste gas enters from the bottom of the packing layer, the scum enters from the upper part of the packing layer, the purified gas is discharged from the top of the tower for further treatment, and the liquid phase is the absorption The scum containing oil and gas is discharged from the bottom of the tower for further treatment; the scum will be divided into tw...

Embodiment 2

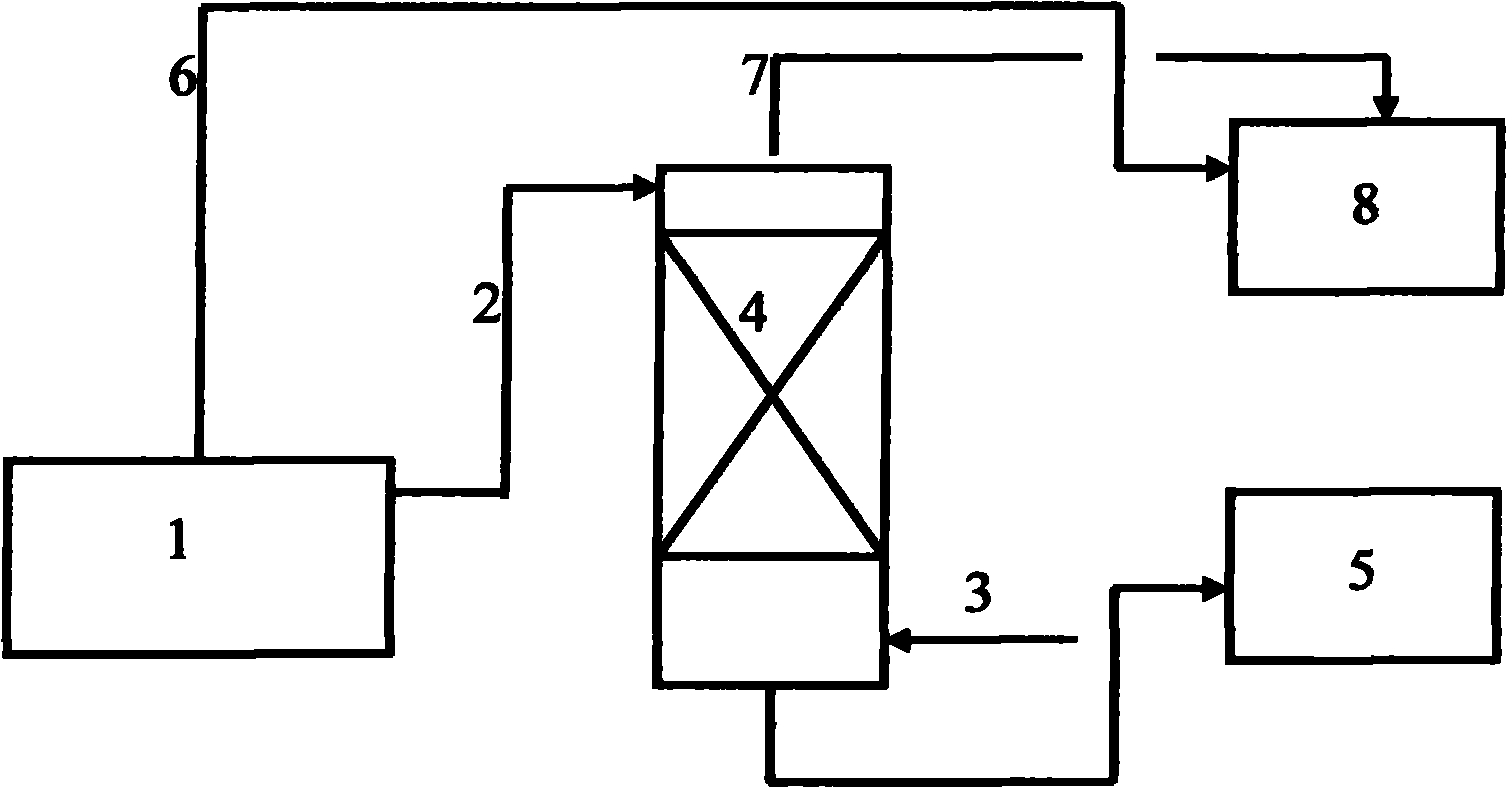

[0022] A certain gasoline oxidative sweetening tail gas and liquid hydrocarbon oxidative sweetening tail gas, the temperature is about 40°C, and the total hydrocarbon concentration is 30×10 4 ~80×10 4 mg / m 3 .

[0023] The absorption treatment device adopts a packed tower, the packing is Φ25mm×25mm×2mm stainless steel Pall ring packing, the waste gas enters from the bottom of the packing layer, the scum enters from the upper part of the packing layer, the purified gas is discharged from the top of the tower for further treatment, and the liquid phase is the absorption The oil and gas scum is discharged from the bottom of the tower for further treatment.

[0024] The operating conditions of the packed tower are: the volume ratio of liquid (scum) to gas (exhaust gas) is 200L / m 3 , the volume space velocity of exhaust gas is 800h -1 , After 12 hours of stable operation, the recovery rate of oil and gas in the exhaust gas is about 82% to 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com