Packed bed microreactor for preparing ethylene by dehydration of bioethanol

A micro-reactor, bio-ethanol technology, which is applied in the production of hydrocarbons from oxygen-containing organic compounds, chemical instruments and methods, chemical/physical processes, etc. Uniform, easy-to-process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

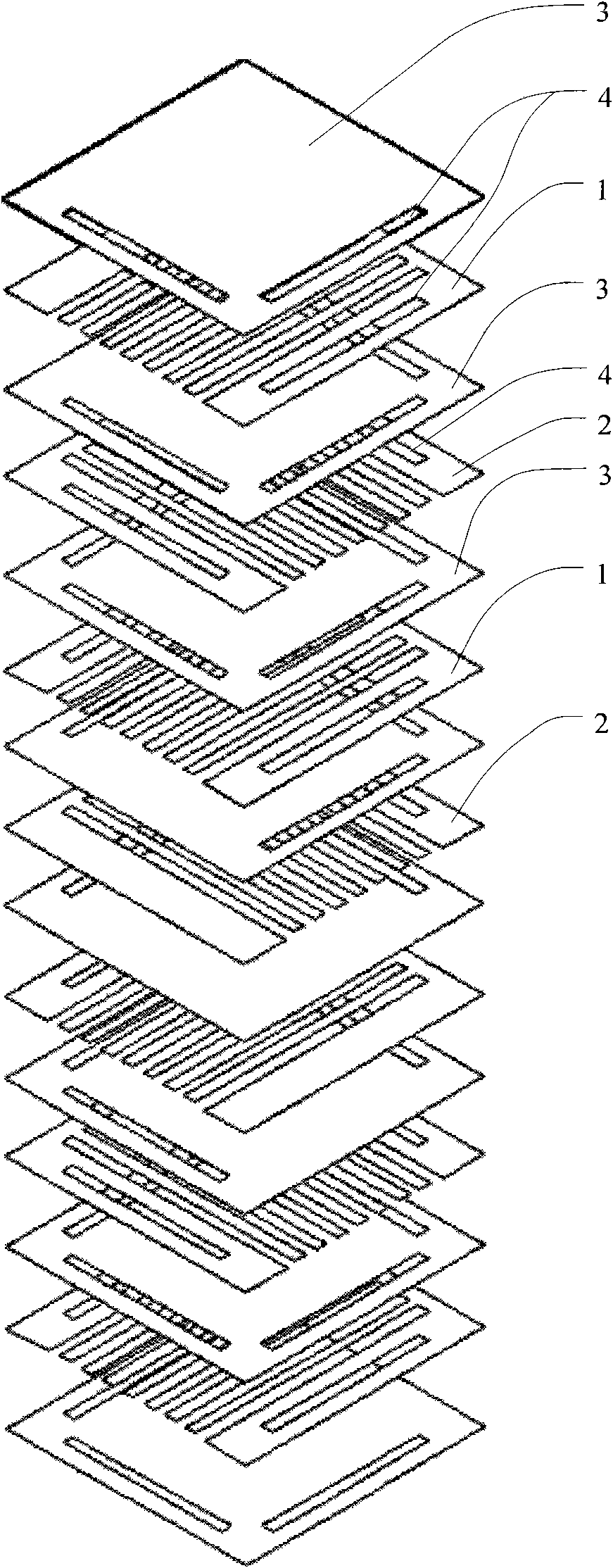

[0026] figure 1Part of one of the most complex implementations of the packed bed microreactor of the invention is disclosed. It includes a plurality of heat-absorbing plate cores 1, heat-radiating plate cores 2, and partitions 3, and a side hole 4 is opened on each heat-absorbing plate core 1, heat-radiating plate core 2 and partition 3. A plate core 2 for catalytic combustion reaction (exothermic) is sandwiched between two adjacent layers of plate cores 1 for catalytic dehydration reaction (endothermic), and is connected by a hole 4 on the side wall of the plate core 2 Become a series or parallel runner plate, plate cores 1 and 2 are arranged in a staggered manner, and all plate cores are closely attached to form a multi-flow plate group for two catalytic reactions (catalytic combustion and catalytic dehydration). In this implementation, each The flow of catalytic reactant flows through two plate cores in each of several flow channel plates to change the flow direction once,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com