Zirconium-based arsenic removing material and preparation method and application thereof

A zirconium-based, nano-zirconia technology, applied in chemical instruments and methods, zirconia, and other chemical processes, can solve problems such as excessive arsenic in water, and achieve the effects of low cost, low hydrothermal reaction temperature, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

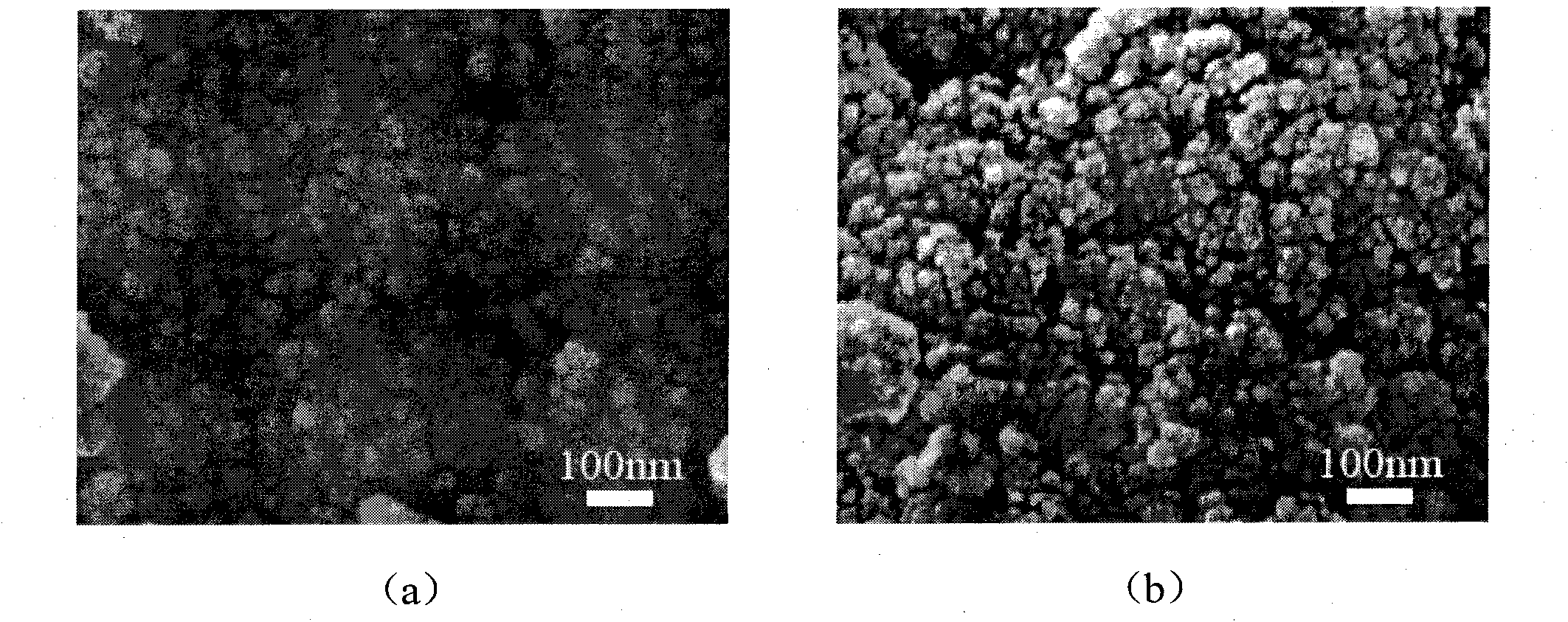

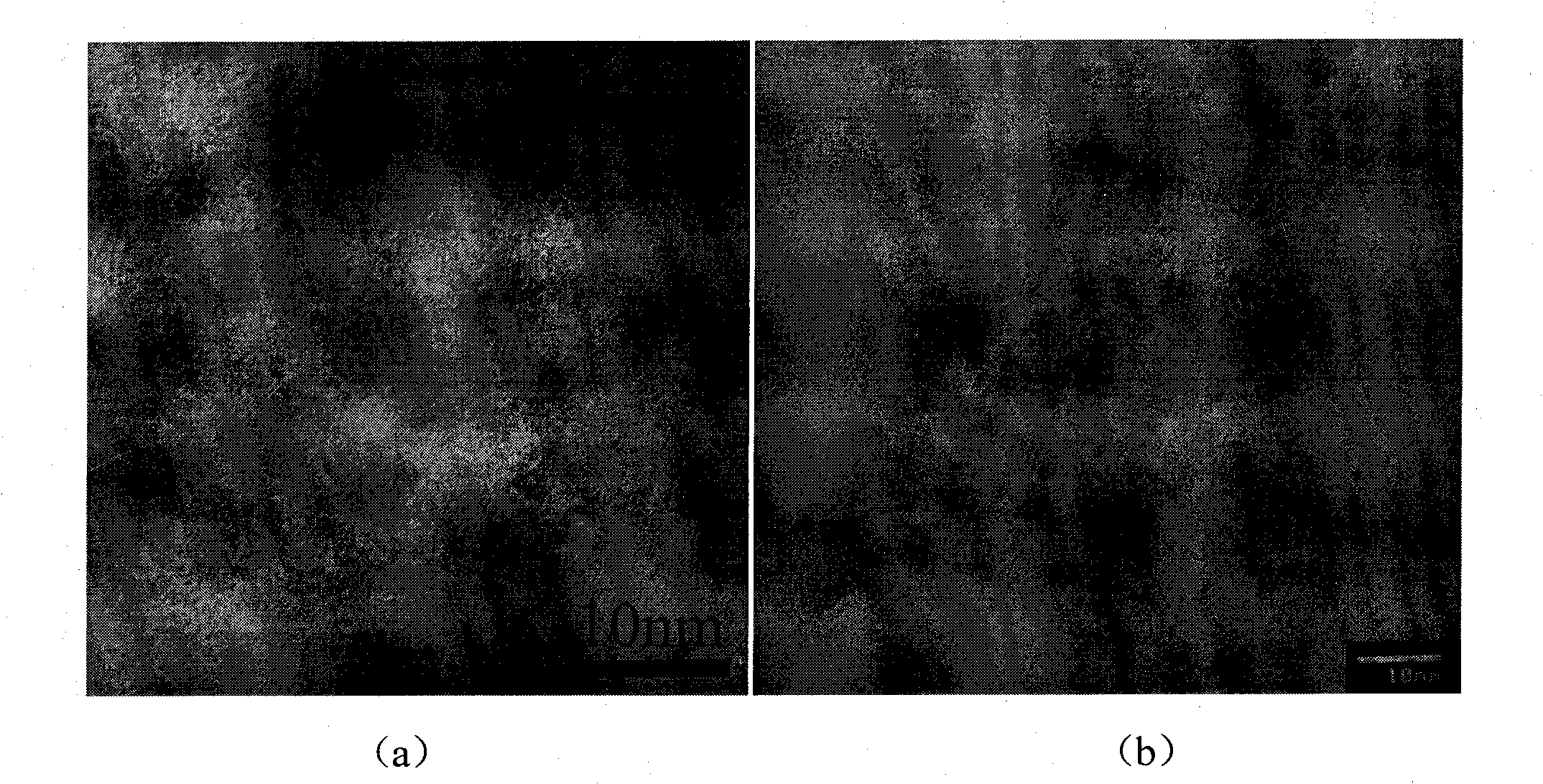

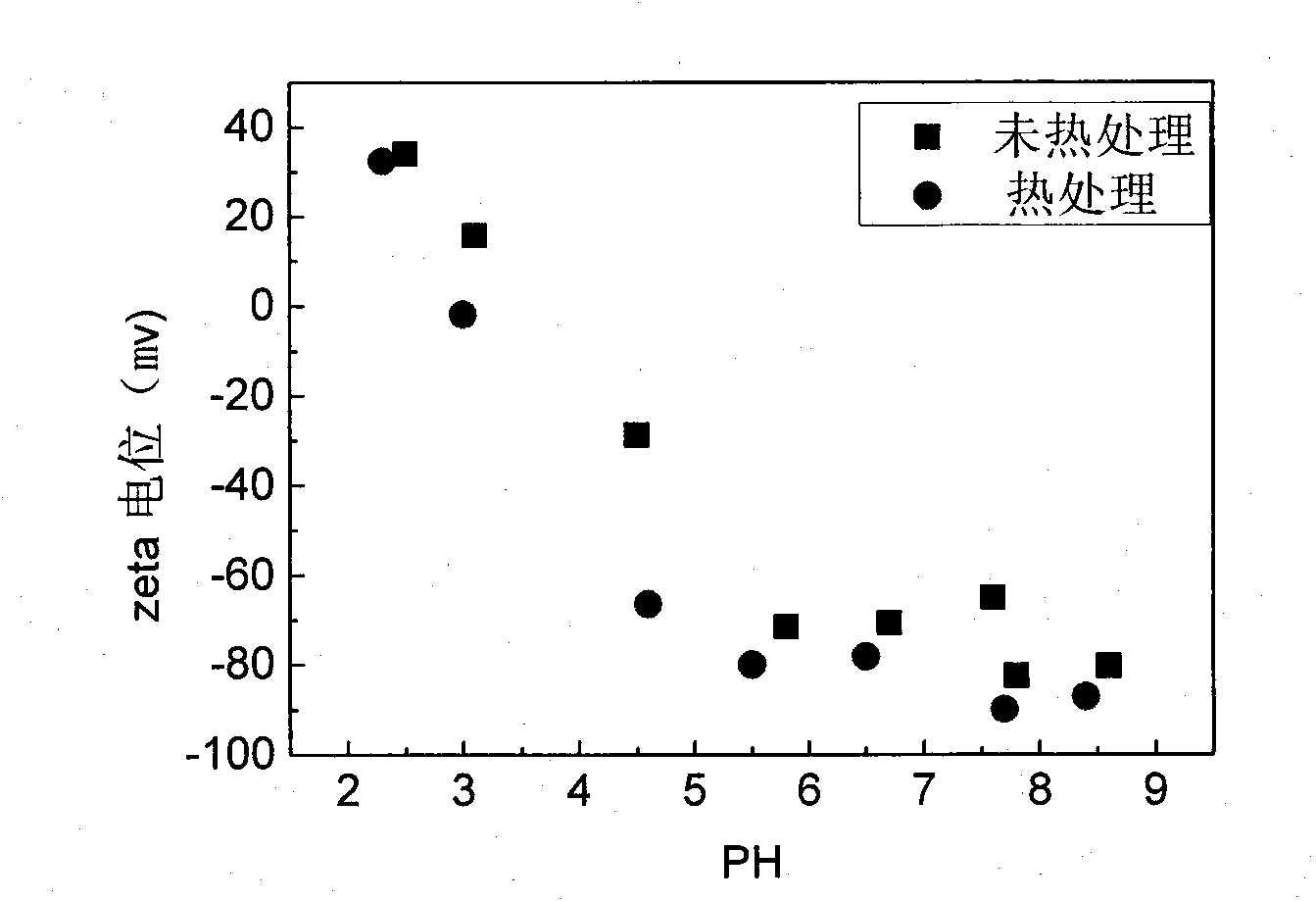

[0029] Such as figure 1 As shown, under the action of magnetic stirring, the ZrOCl 2 ·8H 2 O (11.2791g), water (20mL) and ammonia water (50mL) were mixed thoroughly, then introduced into a polytetrafluoroethylene reactor for hydrothermal reaction, the temperature of the hydrothermal reaction was 150°C, and the hydrothermal time was 3h. Then the precipitate was washed until there was no chloride ion in the silver nitrate test, dried at 110° C. for 8 hours, and finally ground into powder to obtain amorphous zirconia with a particle size of 7.12-13.75 microns. Heat treatment of amorphous nano zirconia powder: temperature is 450-500 DEG C, heat preservation for 1 hour, and then furnace cooled to room temperature to obtain crystallized nano zirconia with a grain size of 7-10nm.

[0030] Such as figure 1 Shown, (a) picture is amorphous zirconia, (b) picture is crystallized zirconia. Depend on figure 1 It can be seen that the prepared nano-zirconia has a relatively serious agglo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com