A nanosheet array nickel cobaltate-carbon composite material and its preparation method and application

A technology of nanosheet array and carbon composite material, which is applied in the field of nanosheet array nickel cobaltate-carbon composite material and its preparation, can solve the problems of poor electrical conductivity, environmental protection, and high cost, and achieve improved electrical conductivity and large specific surface area , the effect of high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This implementation provides a method for preparing a nanosheet array nickel cobaltate-carbon composite material, the method comprising the following steps:

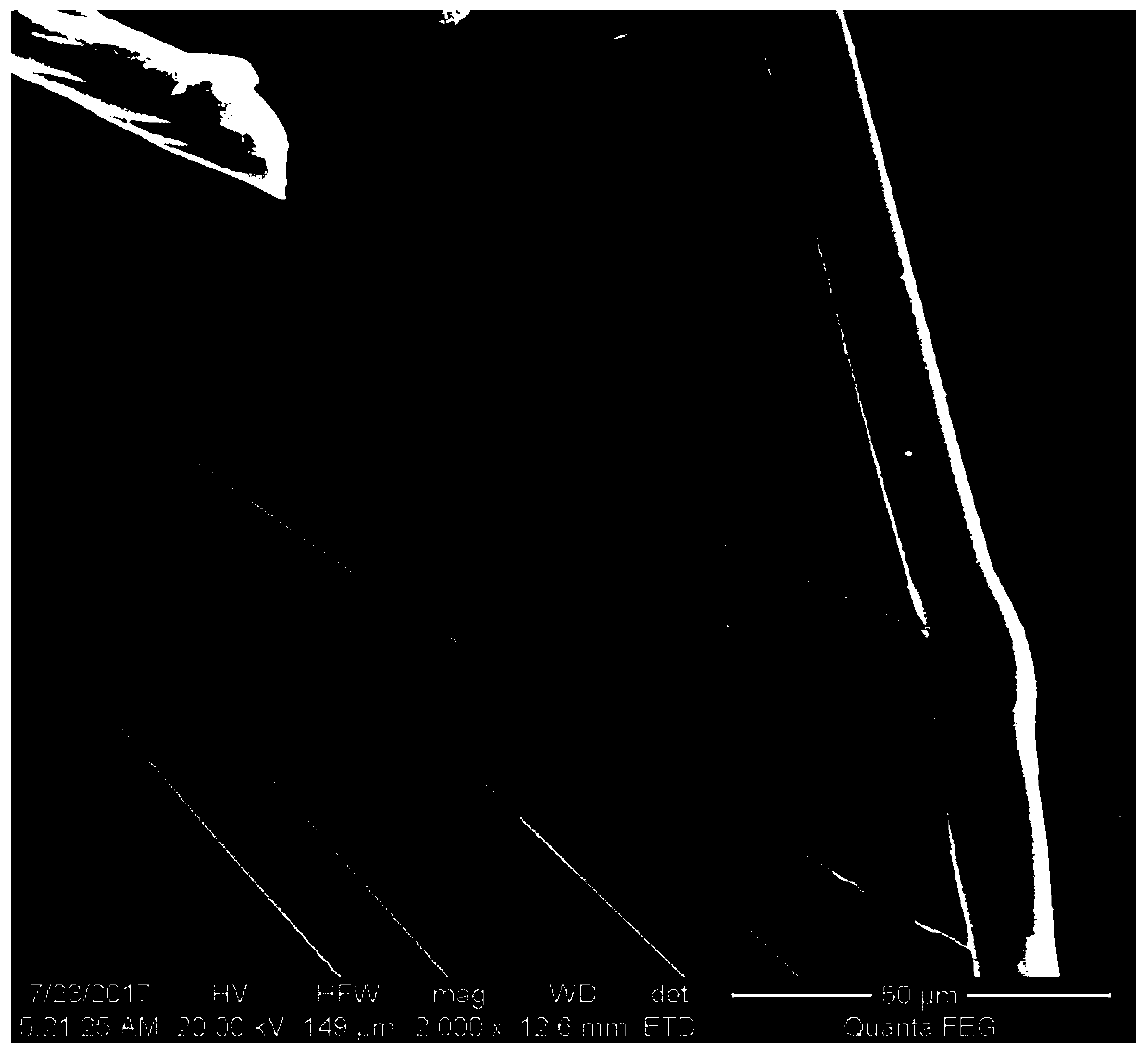

[0042] (1) Put the wet wipes (the SEM picture is as follows figure 1 shown) cut into 1.0cm×1.0cm squares, immersed in 1mol / L hydrochloric acid solution, acetone solution, absolute ethanol solution and deionized water solution in sequence, respectively, and ultrasonically removed the remaining oil stains and other stains on the surface of the wet wipes For residues, the ultrasonic treatment power was 250W, and the ultrasonic treatment time was 10 minutes; the wet wipes after ultrasonic treatment were dried in a vacuum oven at 60° C. for 12 hours to obtain wet wipe fibers.

[0043] (2) 1.1632g of Ni(NO 3 ) 2 ·6H 2 O(2mM), 2.3280g of Co(NO 3 ) 2 ·6H 2 O (4mM), 0.3856g (6.4mM) of urea and 2.4672g of HMT (8.8mM) were added to 40mL of deionized water and 20mL of absolute ethanol, magnetically stirred at room tempe...

Embodiment 2

[0049] This implementation provides a method for preparing a nanosheet array nickel cobaltate-carbon composite material, the method comprising the following steps:

[0050] (1) Put the wet wipes (the SEM image is as shown in figure 1 shown) cut into 1.0cm×1.0cm squares, immersed in 1mol / L hydrochloric acid solution, acetone solution, absolute ethanol solution and deionized water solution in sequence, respectively, and ultrasonically removed the remaining oil stains and other stains on the surface of the wet wipes For residues, the ultrasonic treatment power was 250W, and the ultrasonic treatment time was 10 minutes; the wet wipes after ultrasonic treatment were dried in a vacuum oven at 60° C. for 12 hours to obtain wet wipe fibers.

[0051] (2) 1.1632g of Ni(NO 3 ) 2 ·6H 2 O(2mM), 2.3280g of Co(NO 3 ) 2 ·6H 2 O (4mM), 0.3856g (6.4mM) of urea and 2.4672g of HMT (8.8mM) were added to 40mL of deionized water and 20mL of absolute ethanol, magnetically stirred at room temper...

Embodiment 3

[0058] This implementation provides a method for preparing a nanosheet array nickel cobaltate-carbon composite material, the method comprising the following steps:

[0059] (1) Put the wet wipes (the SEM image is as shown in figure 1 shown) cut into 1.0cm×1.0cm squares, immersed in 1mol / L hydrochloric acid solution, acetone solution, absolute ethanol solution and deionized water solution in sequence, respectively, and ultrasonically removed the remaining oil stains and other stains on the surface of the wet wipes For residues, the ultrasonic treatment power was 250W, and the ultrasonic treatment time was 10 minutes; the wet wipes after ultrasonic treatment were dried in a vacuum oven at 60° C. for 12 hours to obtain wet wipe fibers.

[0060] (2) 1.1632g of Ni(NO 3 ) 2 ·6H 2 O(2mM), 2.3280g of Co(NO 3 ) 2 ·6H 2 O (4mM), 0.3856g (6.4mM) of urea and 2.4672g of HMT (8.8mM) were added to 40mL of deionized water and 20mL of absolute ethanol, magnetically stirred at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com