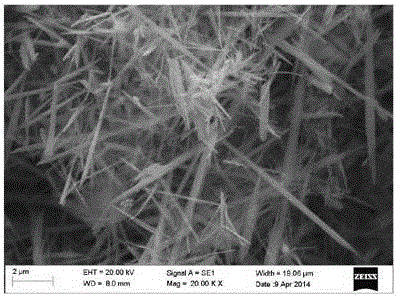

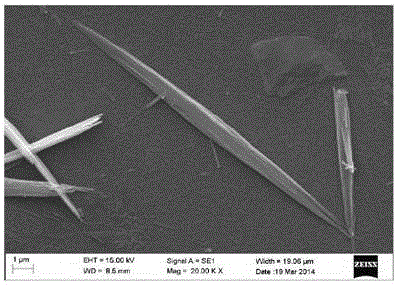

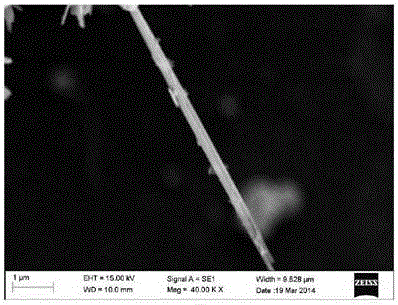

A kind of preparation method of tobernetite whiskers

A xonotlite and whisker technology, which is applied in the preparation and application of inorganic non-metallic materials, can solve the problems of low purity of siliceous raw materials and difficulty in synthesizing calcium silicate whiskers, and achieve excellent thermodynamic stability and beneficial For popularization and application, the effect of low hydrothermal reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention discloses a preparation method of xonotlite whiskers, the specific steps are as follows:

[0024] 1) Grinding the active silica raw material and the lime raw material respectively to obtain active silica powder and lime powder with a particle size of 100-600 mesh; wherein, the SiO2 in the active silica raw material 2 The mass percentage of CaO is 72.90%-98.30%; the mass percentage of CaO in the calcareous raw material is 74.99%-99.10%.

[0025] 2) the active silica powder and lime powder of step 1) are replaced with SiO 2 The / CaO molar ratio is 0.85-1.25 for batching, placed in a closed reaction device, and industrial water is added; wherein, the volume-to-mass ratio of industrial water to the mixture of activated silica powder and lime powder is 15-45; Then heating for synthesis reaction, the heating temperature of the synthesis reaction is 180-225° C., the heating rate is 1.0-30.0° C. / min, and the synthesis reaction time is 2-16 hours; a reaction produ...

example 1

[0033] In this example, the active silicon dioxide raw material and the calcareous raw material are selected from the silicon dioxide slag and quicklime after acid leaching magnesium from chrysotile, respectively.

[0034] 1) Grinding the silica slag after acid leaching magnesium from chrysotile with a silica content of 98.30% and quicklime with a CaO content of 99.10%, respectively, to obtain powders with a particle size of 100 mesh;

[0035] 2) SiO2 slag and unslaked lime powder after the chryserpentine acid leaching magnesium obtained in step 1), according to the chemical composition analysis results, according to SiO 2 The / CaO molar ratio is 0.85, weighed for batching, and placed directly in the reaction kettle with a stirring device, according to the volume mass ratio of industrial water, active silica powder and lime powder mixture of 15:1, add industrial water to mix Evenly, at a heating rate of 1.0°C / min, the temperature was raised to 225°C for hydrothermal reaction, ...

example 2

[0039] The active silicon dioxide raw material and calcareous raw material selected in this example are respectively silica slag and quicklime after extracting magnesium by chrysotile fiber acid salt or ammonium salt roasting. Its preparation method is basically the same as Example 1, and will not be repeated here.

[0040] The differences are:

[0041] 1) The silica slag and quicklime with a CaO content of 98.3% after roasting the chrysotile fiber acid salt or ammonium salt with a silica content of 93.70% and quicklime with a CaO content of 98.3% are ball milled to obtain a material with a fineness of 160 mesh ;

[0042]2) The silicon dioxide slag and calcareous powder after step 1) is roasted to extract magnesium from the ground serpentine fiber acid salt or ammonium salt, according to the chemical composition analysis results, according to SiO 2 The / CaO molar ratio is 1.15 and weighed for batching, and placed directly in the autoclave, according to the volume mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com