Regeneration method of honeycomb activated carbon absorbent for absorbing nitric oxide

A honeycomb activated carbon, nitrogen oxide technology, applied in chemical instruments and methods, separation methods, filter regeneration and other directions, can solve the problems of high cost, complex process, not suitable for regeneration, etc., and achieve the effect of convenient regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

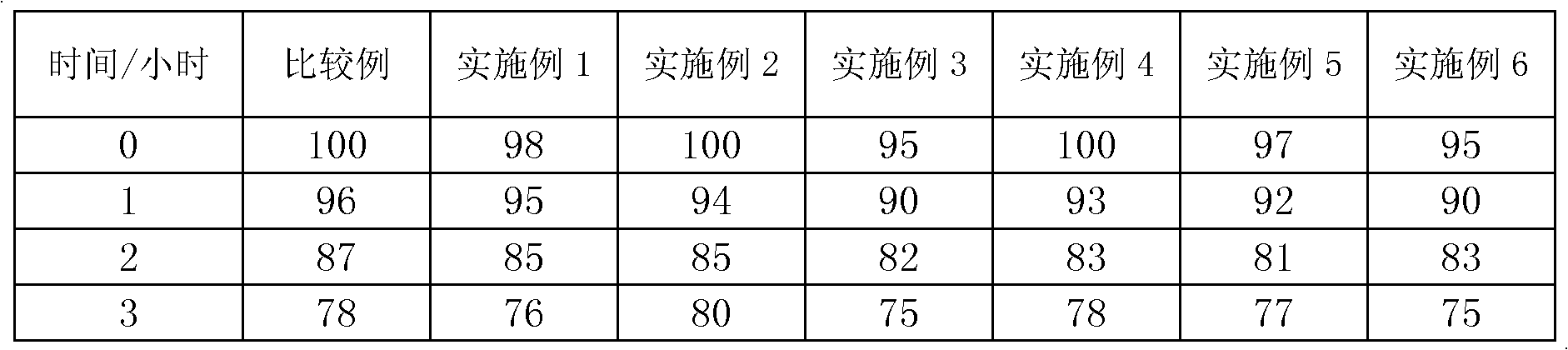

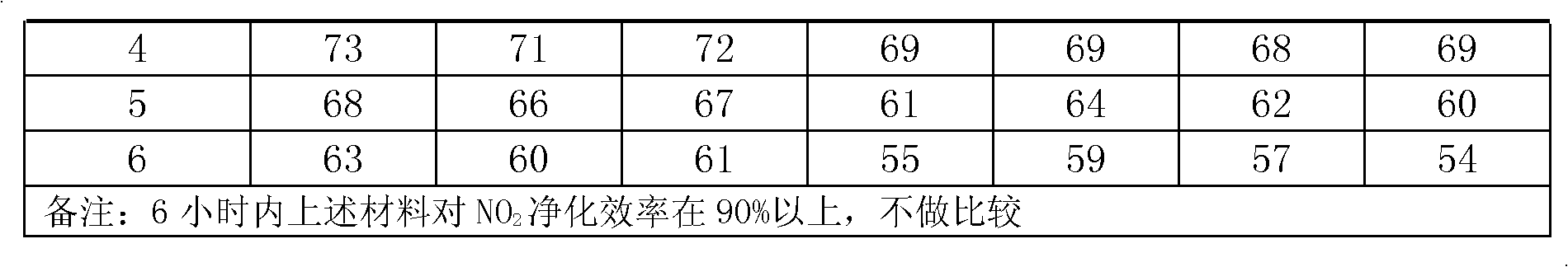

Examples

Embodiment 1

[0021] Place the saturated honeycomb activated carbon adsorbent in a vacuum oven (-0.1mpa) at 100°C for vacuum desorption at room temperature for 5 times;

[0022] Soak the desorbed honeycomb activated carbon adsorbent in 5% ammonia solution for 0.5 hours, then rinse it slowly with water for 5 times, and dry the activated carbon in an oven at 100°C for 8 hours;

[0023] Soak the dried activated carbon in 8% urea solution for 40 minutes, then take it out and dry it in a vacuum oven at 200°C for 2 hours to realize the regeneration of the honeycomb activated carbon.

Embodiment 2

[0025] First, the honeycomb activated carbon adsorbed nitrogen oxides was placed in a 100°C vacuum oven (-0.1mpa) for vacuum desorption at room temperature for 5 times;

[0026] Soak the desorbed activated carbon in 5% ammonia solution for 0.5 hours, then rinse it slowly with water for 5 times, then dry the activated carbon in an oven at 100°C for 8 hours;

[0027] Soak the dried activated carbon in 3% urea solution for 40 minutes, then take it out and dry it in a vacuum oven at 200°C for 2 hours to realize the regeneration of the honeycomb activated carbon.

Embodiment 3

[0029] First, the honeycomb activated carbon adsorbed nitrogen oxides was placed in a 100°C vacuum oven (-0.1mpa) for vacuum desorption at room temperature for 5 times;

[0030] Soak the desorbed activated carbon in 5% ammonium bicarbonate solution for 0.5 hours, then rinse slowly with clean water for 3 times, and dry the activated carbon in an oven at 100°C for 8 hours;

[0031] Soak the dried activated carbon in 8% urea solution for 20 minutes, then take it out and dry it in a vacuum oven at 180°C for 3 hours to realize the regeneration of the honeycomb activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com