Hydrothermal preparation method and product of film nano material with photocatalysis property

A nanomaterial and photocatalytic technology, which is applied in the field of hydrothermal preparation of thin film nanomaterials with photocatalytic properties, can solve problems such as lack of photocatalytic properties, and achieve the effects of firm bonding and improved ultraviolet photocatalytic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a thin film nanomaterial with photocatalytic properties by a hydrothermal method, wherein the photocatalytic properties are ultraviolet light and visible light photocatalytic properties, comprising the steps of:

[0031] Step 1: Dissolve 2.6g of sodium tungstate dihydrate solution in 40ml of deionized water as a concentration regulator, and adjust the concentration of sodium tungstate solution to 0.2 mol / L;

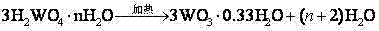

[0032] The second step: the sodium tungstate solution passes through the reactor containing the exchange column of 732 type cation exchange resin to obtain a yellow solution (H 2 WO 4 ·nH 2 O);

[0033] Step 3: Add 1ml of hydrogen peroxide as an acidity regulator to the tungstic acid solution, and adjust the pH of the tungstic acid solution to 1.5;

[0034] Step 4: Put the tungstic acid solution into the reaction kettle, add the base material glass sheet at the same time, and form WO on the glass sheet after hydrothermal reaction at 150°C ...

Embodiment 2

[0040] A method for preparing a thin film nanomaterial with photocatalytic properties by a hydrothermal method, wherein the photocatalytic properties are ultraviolet light and visible light photocatalytic properties, comprising the steps of:

[0041] Step 1: Dissolve 2.6g of sodium tungstate dihydrate solution in 40ml of deionized water as a concentration regulator, and adjust the concentration of sodium tungstate solution to 0.2 mol / L;

[0042] The second step: the sodium tungstate solution passes through the reactor containing the exchange column of 732 type cation exchange resin to obtain a yellow solution (H 2 WO 4 ·nH 2 O);

[0043]Step 3: Add 1ml of hydrogen peroxide as an acidity regulator to the tungstic acid solution, adjust the pH of the tungstic acid solution to 1.5, and add 3ml of 1mol / L phosphoric acid solution;

[0044] Step 4: Put the tungstic acid solution into the reaction kettle, add the base material glass sheet at the same time, and form WO on the glass ...

Embodiment 3

[0049] A method for preparing a thin film nanomaterial with photocatalytic properties by a hydrothermal method, wherein the photocatalytic properties are ultraviolet light and visible light photocatalytic properties, comprising the steps of:

[0050] Step 1: Dissolve the sodium tungstate dihydrate solution in the concentration regulator ethanol + deionized water, and adjust the concentration of the sodium tungstate solution to 0.3 mol / L;

[0051] The second step: the sodium tungstate solution passes through the reactor containing the exchange column of 732 type cation exchange resin to obtain a yellow solution (H 2 WO 4 ·nH 2 O);

[0052] Step 3: Add acidity regulator acetic acid to the tungstic acid solution, adjust the pH of the tungstic acid solution to 1.6, and add 2.0ml 1.5mol / L titanium tetrachloride solution;

[0053] Step 4: Put the tungstic acid solution into the reaction kettle, and add the base material glass sheet at the same time. After hydrothermal reaction at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com