Advanced treatment and recycling device and method of papermaking wastewater

A technology for papermaking wastewater and advanced treatment, which is applied in processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of paper discharge, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

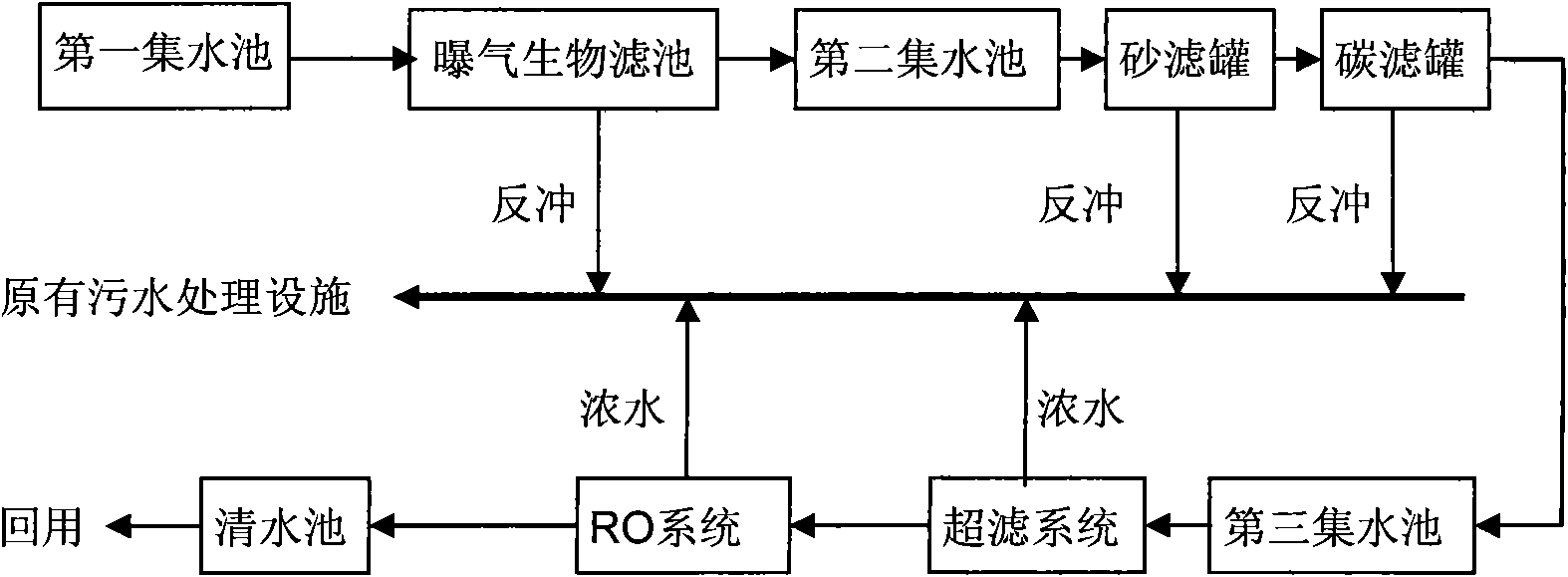

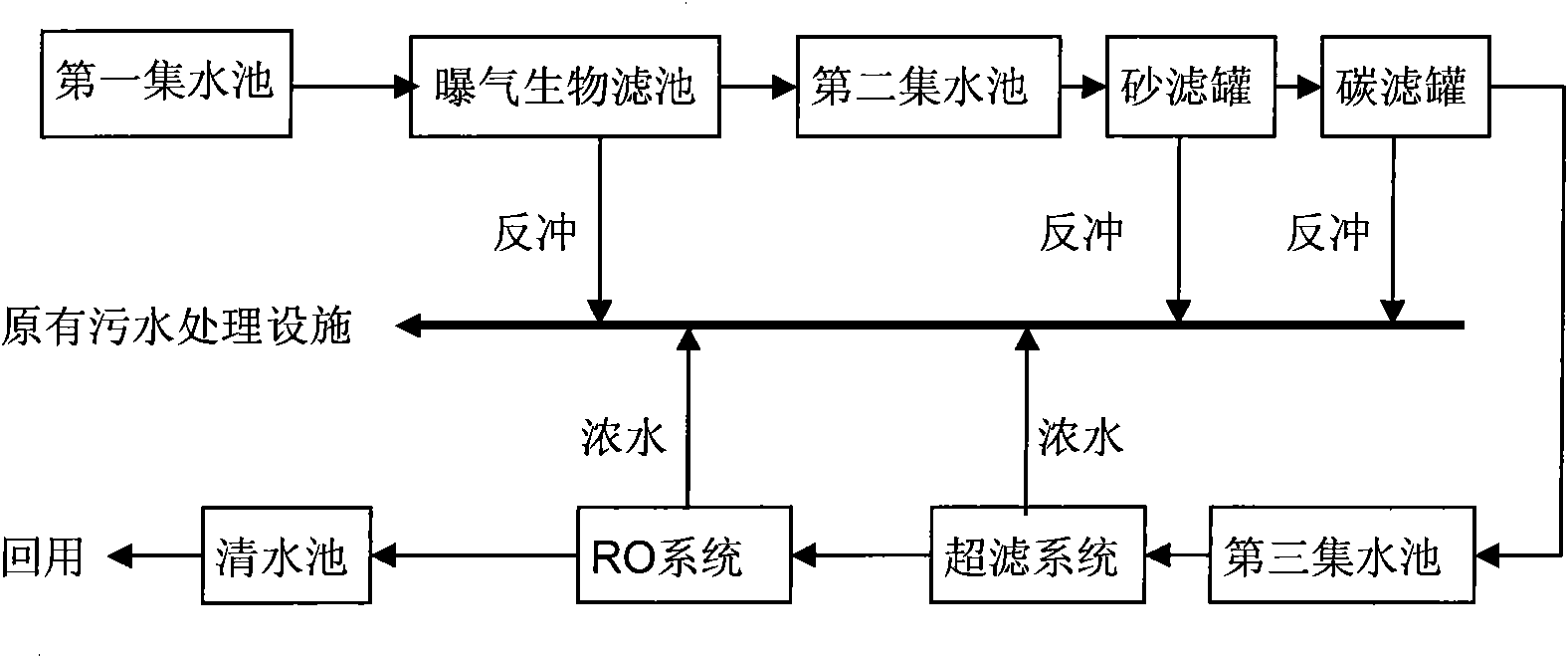

Method used

Image

Examples

Embodiment 1

[0031] After the secondary treatment, the papermaking wastewater enters the first sump for water quality regulation. The inflow and outflow of the first sump is 96m 3 / d, the water quality is as follows: pH is 6.78, COD Cr 200mg / L, BOD 44mg / L, turbidity 10NTU, chromaticity 300 times, conductivity 3000μs / cm 2 .

[0032] Wastewater from the first sump is 96m 3 The flow rate of / d enters the biological aerated filter, and the residence time is 4.9h, and most of the soluble organic pollutants in the wastewater are degraded by microorganisms. After treatment, the effluent water quality is as follows: pH is 7.13, COD Cr 80mg / L, BOD 15mg / L, turbidity 4NTU, chromaticity 210 times, conductivity 3000μs / cm 2 , the effluent enters the second sump for water quality regulation.

[0033] Wastewater from the second sump is 96m 3 The flow rate of / d enters the sand filter tank and the carbon filter tank successively, and the chroma and COD of the wastewater are removed by the adsorption...

Embodiment 2

[0038] After the secondary treatment, the papermaking wastewater enters the first sump for water quality regulation. The inflow flow of the first sump is 72m 3 / d, the water quality is as follows: pH is 7.78, COD Cr 200mg / L, BOD 44mg / L, turbidity 10NTU, chromaticity 300 times, conductivity 3000μs / cm 2 .

[0039] The waste water of the first sump is 72m 3The flow rate of / d enters the biological aerated filter, the residence time is 3.6h, and 5g of diammonium hydrogen phosphate is added per ton of wastewater as a nitrogen and phosphorus source, and most of the soluble organic pollutants in the wastewater are degraded by microorganisms. After treatment, the effluent water quality is as follows: pH is 7.53, COD Cr 80mg / L, BOD 11mg / L, turbidity 4NTU, chromaticity 190 times, conductivity 3000μs / cm 2 . The effluent enters the second sump for water quality regulation.

[0040] Wastewater from the second sump is 72m 3 The flow rate of / d enters the sand filter tank and the car...

Embodiment 3

[0045] After the secondary treatment, the papermaking wastewater enters the first sump for water quality regulation. The influent flow rate of the first sump is 96m 3 / d, the water quality is as follows: pH is 7.48, COD Cr 150mg / L, BOD 35mg / L, turbidity 11NTU, chromaticity 270 times, conductivity 2500μs / cm 2 .

[0046] Wastewater from the first sump is 96m 3 The flow rate of / d enters the biological aerated filter tank, the residence time is 4.9h, and 2g of urea is added as a nitrogen source and 3g of diammonium hydrogen phosphate as a phosphorus source per ton of wastewater, and most of the soluble organic pollutants in the wastewater are degraded by microorganisms. After treatment, the effluent water quality is as follows: pH is 7.33, COD Cr 75mg / L, BOD 13mg / L, turbidity 4NTU, color 163 times, conductivity 3000μs / cm 2 , the effluent enters the second sump for water quality regulation. .

[0047] Wastewater from the second sump is 96m 3 The flow rate of / d enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com