Production process of special low-carbon steel slag cement

A technology of steel slag and cement, which is applied in the direction of cement production, etc., can solve the problems of occupying farmland land, large fluctuations in chemical composition, high hardness, etc., and achieve the effect of reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

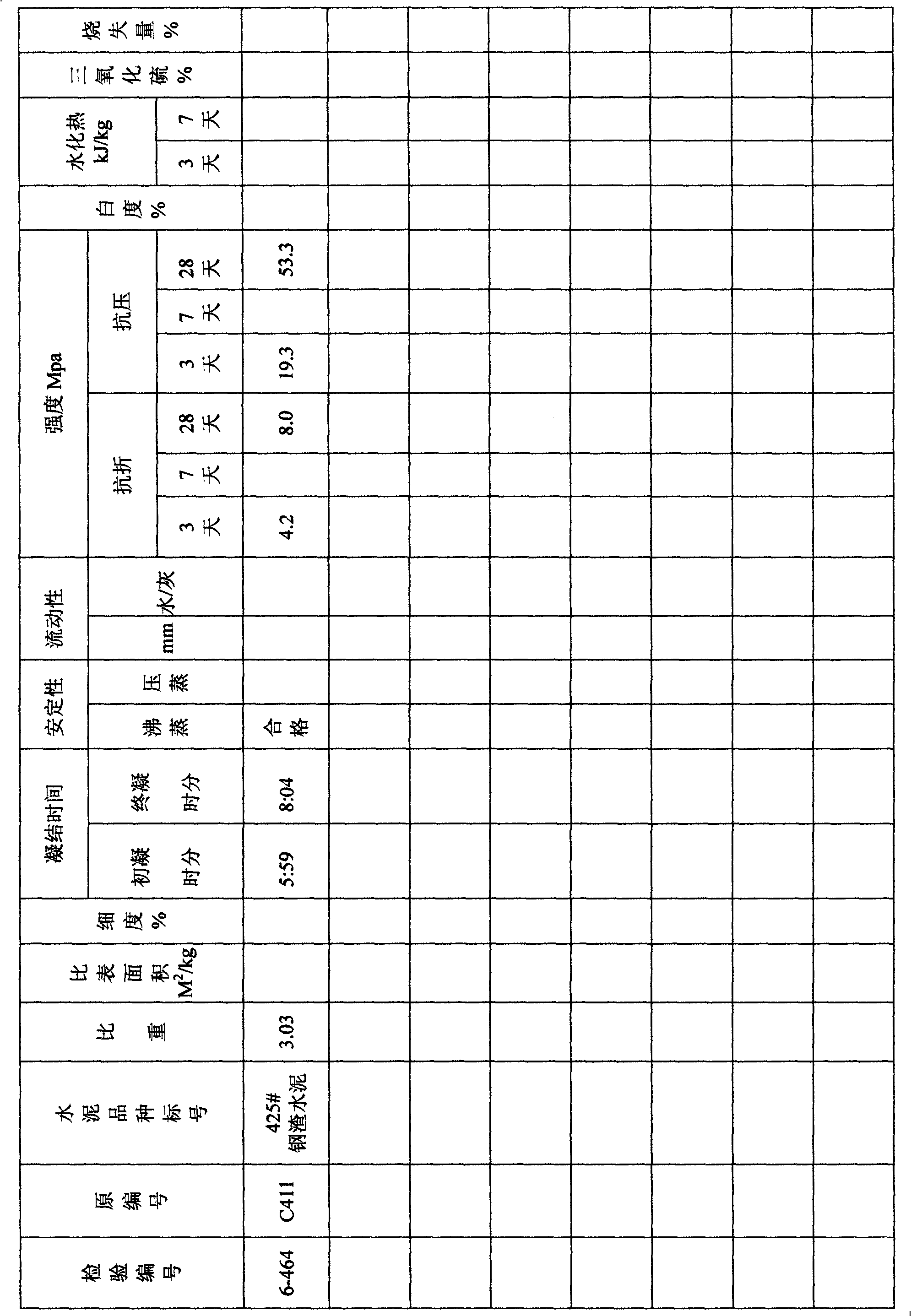

Image

Examples

Embodiment Construction

[0010] The hardness of steel slag is relatively high, with a Mohs hardness of 6-7, and slag steel particles are wrapped in the slag. Therefore, crushing and grinding are relatively difficult, and the particle size of steel slag directly affects the output and grinding fineness of steel slag cement. Three crushing and three magnetic separations are used in production, plus a closed-circuit pre-grinding system. After being processed by this system, the particle size and metal content of the steel slag are greatly reduced, the burden on the mill is relieved, the grinding time is shortened, the output and quality of the cement mill are improved, and the energy consumption is reduced. The steel slag is individually ground to a fineness that meets the process requirements, and stored in the finished product warehouse.

[0011] Granulated blast furnace slag is a glassy substance that is mostly formed when the molten slag of blast furnace ironmaking is quenched, and it is too late to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com