Vanadium-titanium vermicular cast iron brake drum and preparation method thereof

A technology of vermicular graphite cast iron and brake drum, applied in the field of preparation of automobile brake drum, can solve the problems of poor strength, wear resistance, thermal fatigue resistance and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

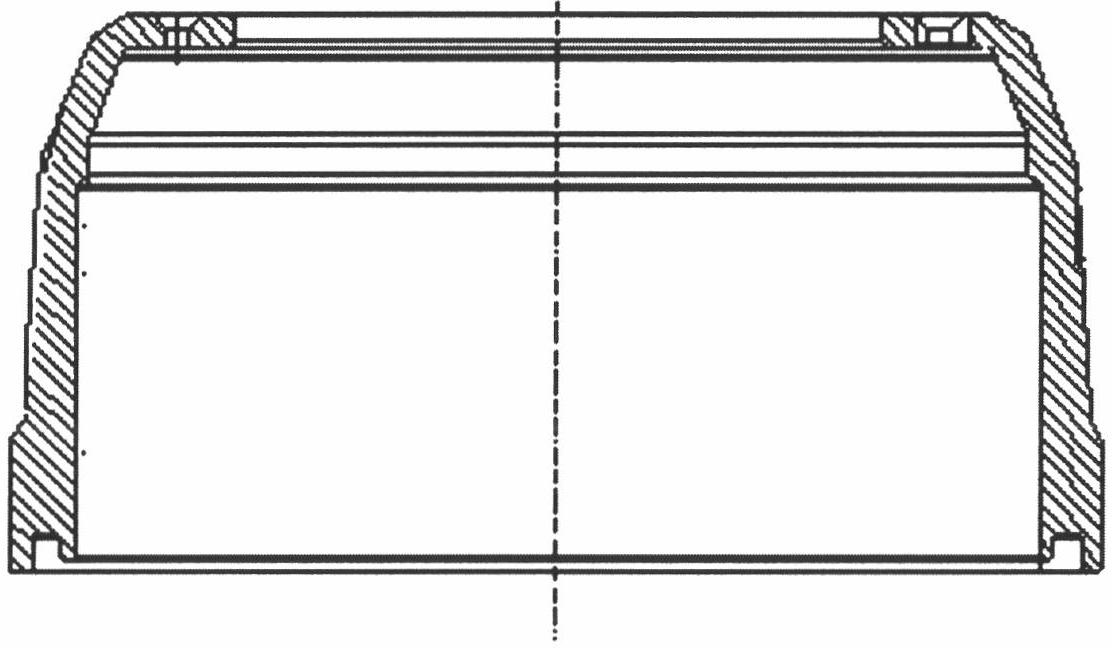

Image

Examples

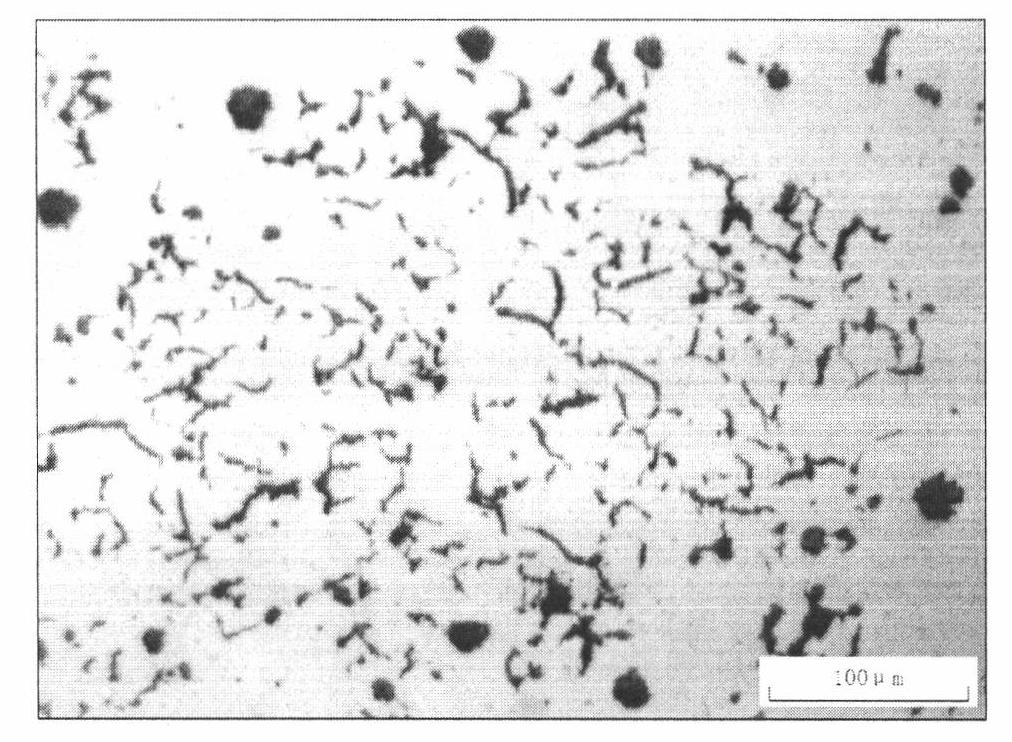

Embodiment 1

[0041] The brake drum preparation method of embodiment 1 is as follows: configure the following components by weight percentage: carbon is 3.4%, silicon is 2.8%, manganese is 0.9%, phosphorus is 0.10%, sulfur is 0.07%, vanadium is 0.10%; Titanium is 0.10%, and the balance is iron and unavoidable impurities. The 1320°C high-temperature molten iron obtained after melting the vanadium-titanium magnetite is directly transferred to the intermediate frequency furnace for smelting, and the melting temperature is 1560°C. Before the molten iron is released from the furnace, the pouring treatment ladle is baked at 300°C, and then the vermicular agent, 2 / 3 of 75SiFe and polyslag are placed at the bottom of the ladle for compaction; the vermicular agent is made of rare earth ferrosilicon and rare earth magnesium ferrosilicon. Mixture, the percentage by weight of rare earth ferrosilicon in the vermicular agent is 60%, the specific composition of rare earth ferrosilicon and rare earth magne...

Embodiment 2

[0048] The preparation method of the brake drum of embodiment 2 is as follows: carbon is 3.7%, silicon is 2.6%, manganese is 0.7%, phosphorus is 0.09%, sulfur is 0.05%, vanadium is 0.2%; titanium is 0.15%, and the balance is iron and unavoidable impurities. The 1330°C high-temperature molten iron obtained after melting the vanadium-titanium magnetite is directly transferred to the intermediate frequency furnace for smelting, and the smelting temperature is 1530°C. Before the molten iron comes out of the furnace, the pouring treatment bag is baked at 350°C, and then the vermicular agent, 2 / 3 of 75SiFe and polyslag are placed at the bottom of the bag for compaction; the vermicular agent is made of rare earth ferrosilicon and rare earth magnesium ferrosilicon. Mixture, the percentage by weight of rare earth ferrosilicon in the vermicular agent is 70%, the specific composition of rare earth ferrosilicon and rare earth magnesium ferrosilicon is as shown in Table 1 and Table 2, the ...

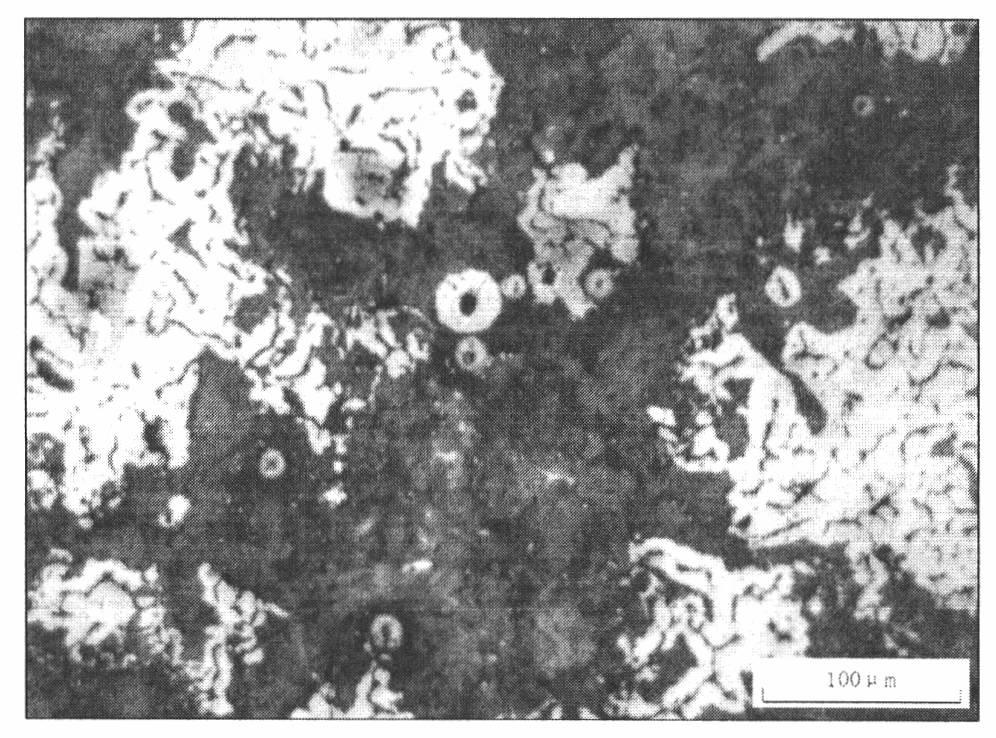

Embodiment 3

[0051] The preparation method of the brake drum of embodiment 3 is as follows: carbon is 3.9%, silicon is 2.1%, manganese is 0.5%, phosphorus is 0.08%, sulfur is 0.03%, vanadium is 0.35%; titanium is 0.25%, and the balance is iron and unavoidable impurities. The 1350°C high-temperature molten iron obtained after melting the vanadium-titanium magnetite is directly transferred to the intermediate frequency furnace for smelting, and the melting temperature is 1500°C. Before the molten iron comes out of the furnace, the pouring treatment ladle is baked at 450°C, and then the vermicular agent, 2 / 3 of 75SiFe and polyslag are placed at the bottom of the ladle for compaction; the vermicular agent is made of rare earth ferrosilicon and rare earth magnesium ferrosilicon. Mixture, the percentage by weight of rare earth ferrosilicon in the vermicular agent is 80%, the specific composition of rare earth ferrosilicon and rare earth magnesium ferrosilicon is as shown in Table 1 and Table 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com