Automatic control system for winch and control method of automatic control system

An automatic control system and winch technology, applied in drilling equipment and methods, earthwork drilling, winch and other directions, can solve problems such as the maximum tension limit, shorten the motion compensation stroke, meet the drilling production operation conditions, Reduce the effect of human manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

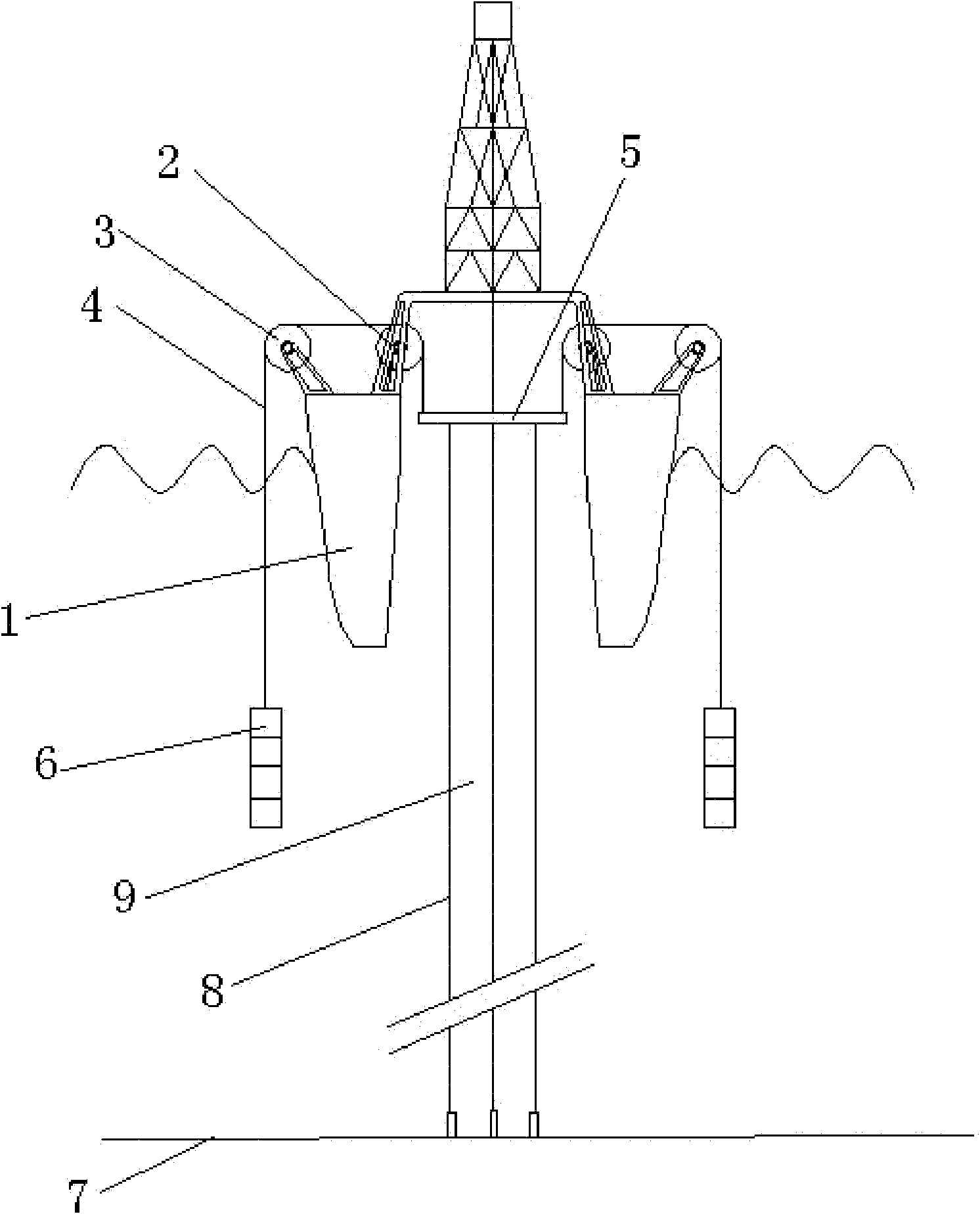

[0013] Such as figure 1 As shown, the present invention comprises the drilling moon pool arranged on the hull 1, the drilling moon pool is circumferentially provided with several winches 2 and pulleys 3, and one end of the cable 4 on each winch 2 suspends a drilling deck 5 jointly, and the drilling deck 5 is suspended in the drilling moon pool, and the other end of each steel cable 4 respectively bypasses a pulley 3 and connects to a counterweight 6 suspended on the outer side. The bottom of the drilling deck 5 is provided with a production riser 8 leading to the seabed 7 and a drilling compartment. water pipe9.

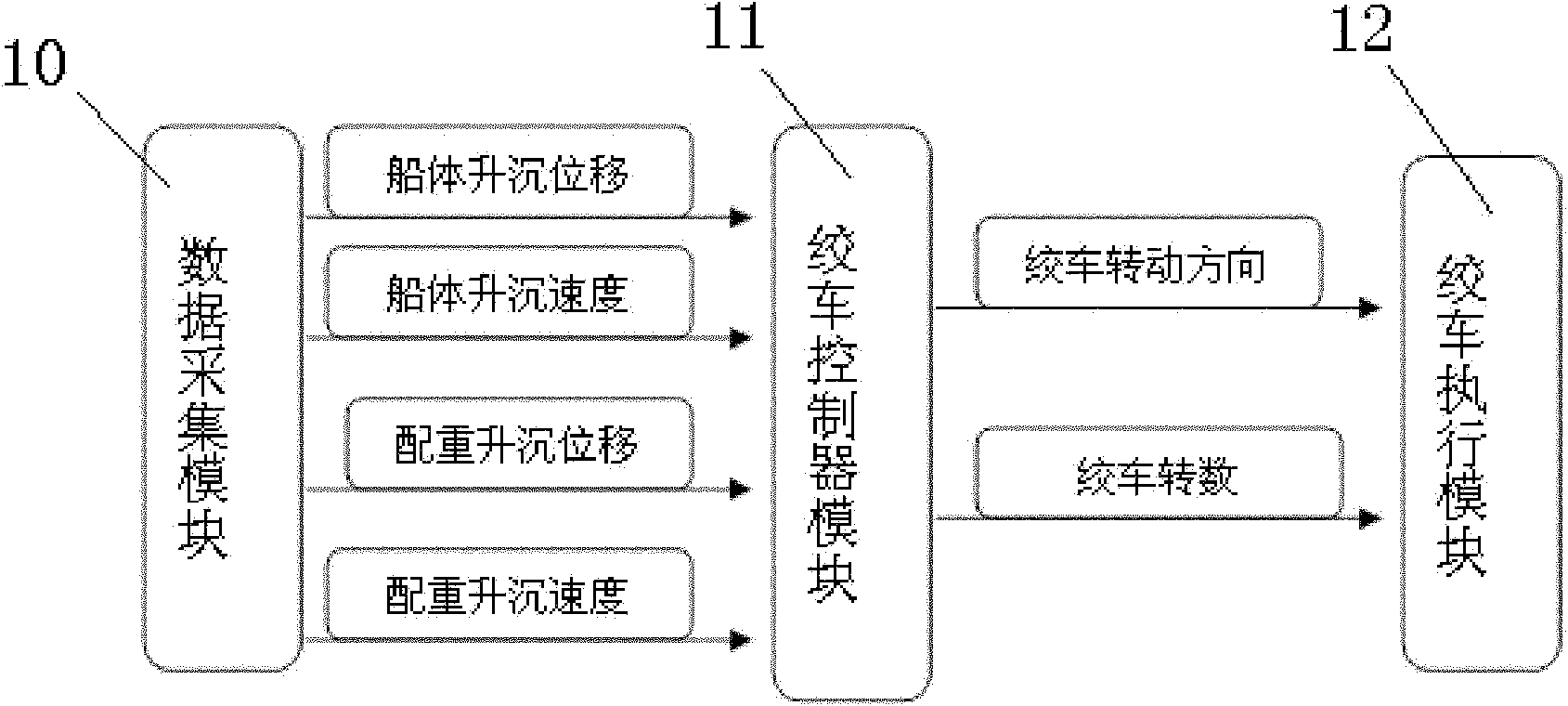

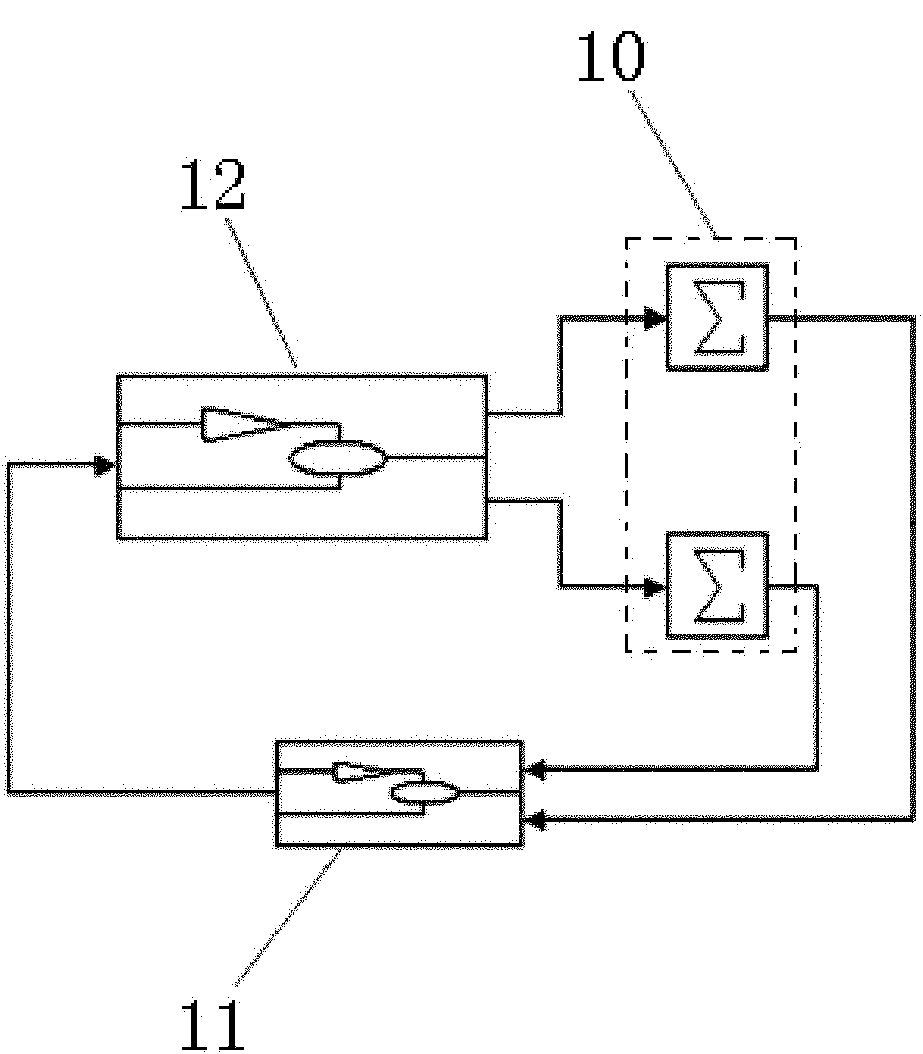

[0014] Such as figure 2 , image 3 As shown, the present invention also includes a data acquisition module 10 , a winch control module 11 and a winch execution module 12 .

[0015] The data acquisition module 10 includes a displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com