Device for measuring scattering property of light diffuser and measurement method thereof

A technology of scattering characteristics and measuring device, applied in the field of lithography, can solve the problems of inaccurate measurement of the mirror image aberration of the projection object, inability to measure the mirror image difference of the projection object, etc., and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

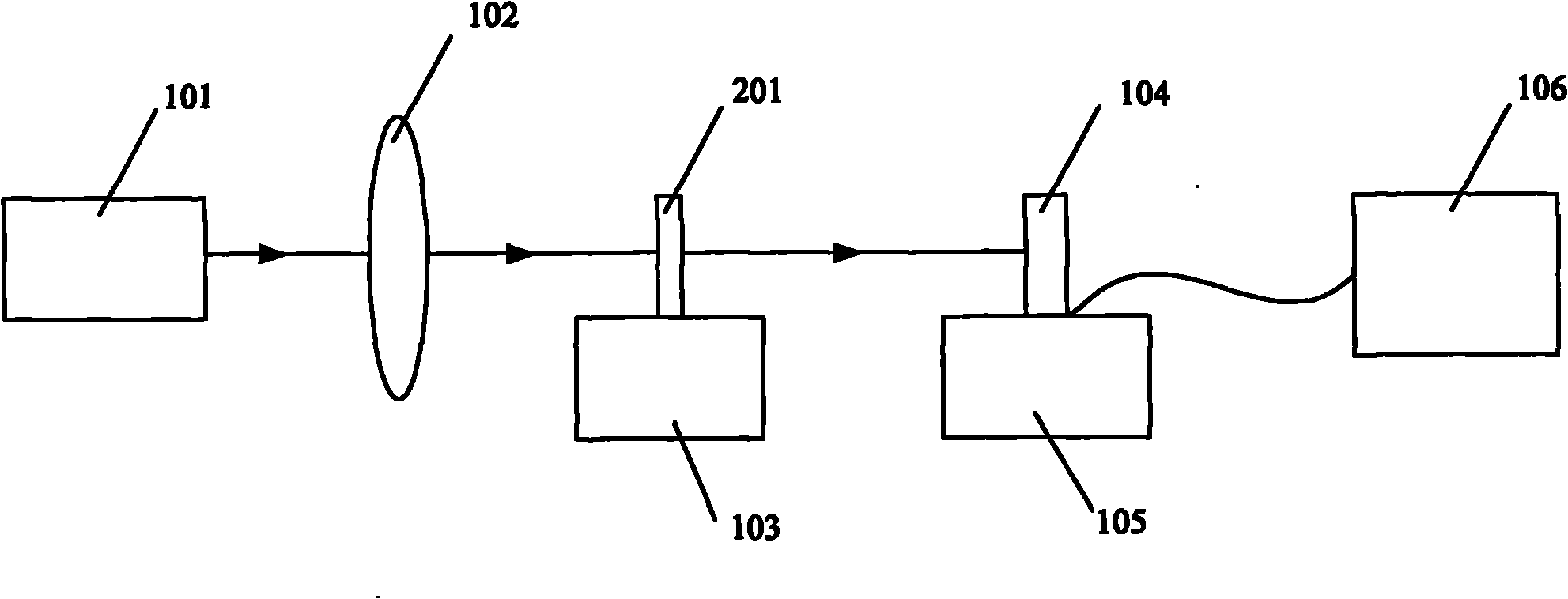

[0047] The light source 101 adopts a tunable excimer laser light source whose working gas is argon (Ar) and fluorine (F) mixed gas. The light source 101 outputs deep ultraviolet light with a wavelength of 193nm. The output spot size of the light source 101 is 6mm ×3mm, its repetition frequency can be tuned in the range of 10Hz-500Hz, and its pulse energy can be tuned in the range of 2mJ-5mJ.

[0048] For the light source 101 to output deep ultraviolet light with a wavelength of 193nm, the numerical aperture NA of the illumination objective lens 102 can be adjusted in the range of 0.17-0.05, and the field of view of the illumination objective lens 102 is 1 mm.

[0049] The minimum scale of the rotating dial of the light diffuser moving platform 103 is 1 degree.

[0050] The minimum scale of the graduated head of the detector motion platform 105 is 1 micron.

[0051] The size of the photosensitive pixel of the detector 104 is 25um×25um, and the photosensitive surface is an arra...

Embodiment 2

[0062] The light source 101 adopts a tunable excimer laser light source whose working gas is a mixture of krypton gas (Kr) and fluorine gas (F). The light source 101 outputs deep ultraviolet light with a wavelength of 248nm. The output spot size of the light source 101 is 6mm ×3mm, its repetition frequency can be tuned in the range of 10Hz-500Hz, and its pulse energy can be tuned in the range of 2mJ-5mJ.

[0063] For the light source 101 to output deep ultraviolet light with a wavelength of 248nm, the numerical aperture NA of the illumination objective lens 102 can be adjusted in the range of 0.13-0.04, and the field of view of the illumination objective lens 102 is 1mm.

[0064] The minimum scale of the rotating dial of the light diffuser moving platform 103 is 1 degree.

[0065] The minimum scale of the graduated head of the detector motion platform 105 is 1 micron.

[0066] The size of the photosensitive pixel of the detector 104 is 25um×25um, and the photosensitive surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com