Full digitalized distributed intelligent servo driver

A servo drive, all-digital technology, applied in the field of servo drives, can solve problems such as poor scalability of the number of system control axes, difficulty in increasing the number of system control axes, failure to obtain drive parameters and information, etc., to achieve communication speed and reliability Improvement , reduce the point of failure, and feature-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

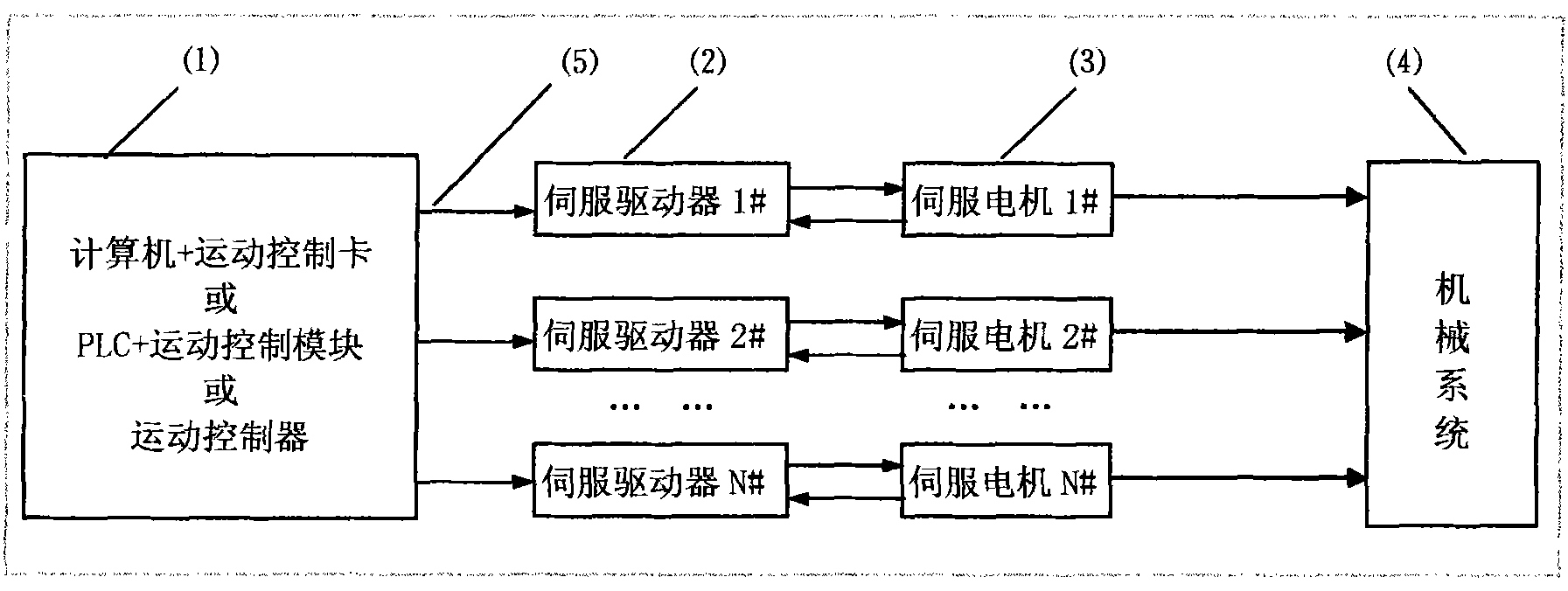

[0047] In order to make the implementation method, technical solution and advantages of the present invention clearer, the following describes the proposed distributed intelligent servo driver with reference to the accompanying drawings and examples to illustrate the embodiments, and further describes the present invention in detail.

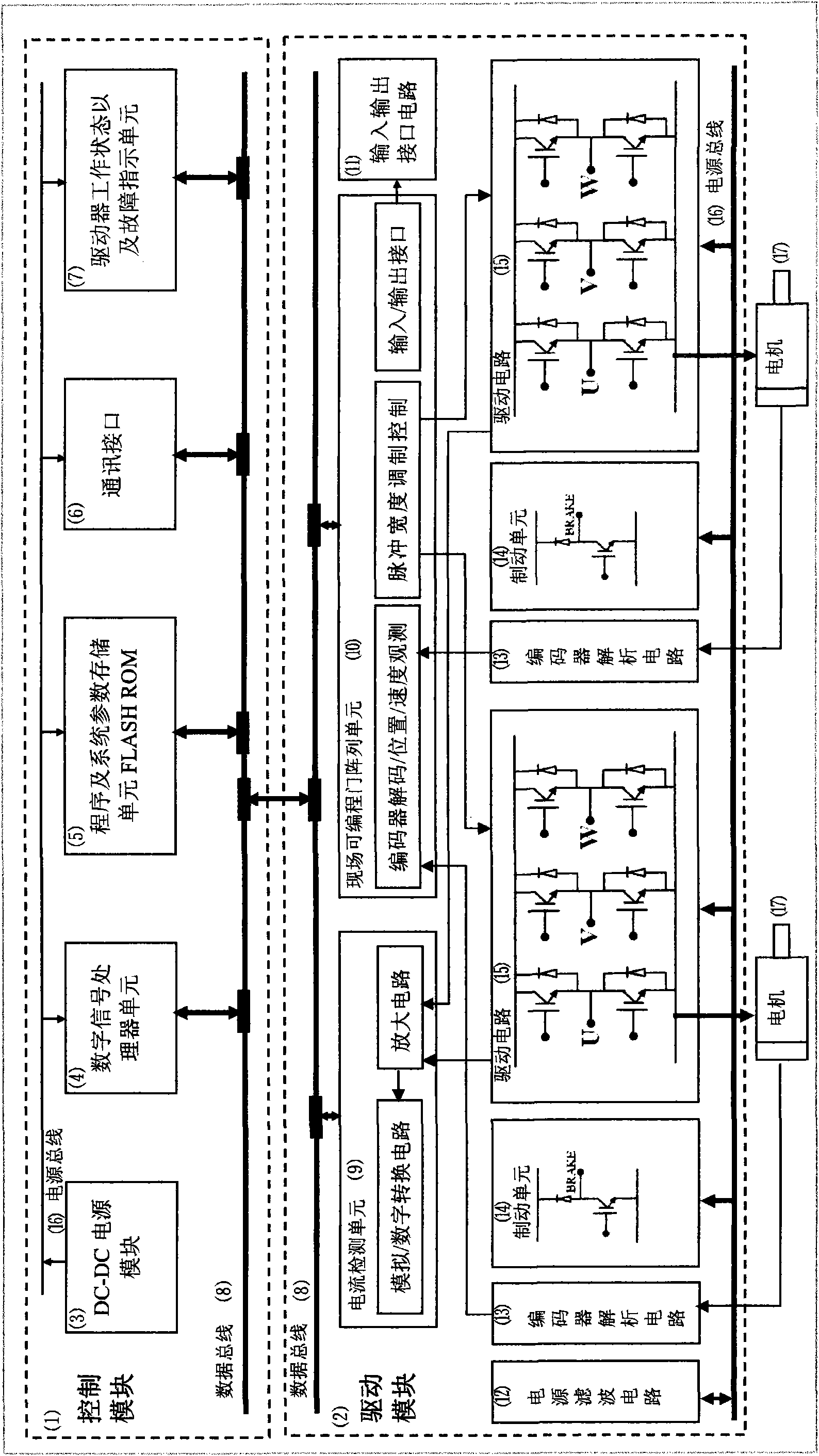

[0048] Figure 2 isSchematic diagram of the structure of the distributed intelligent servo driver proposed by the present invention;

[0049] The intelligent servo driver proposed by the present invention consists of two parts, namely (1) a control module and (2) a drive module. The control module (1) realizes the motion control function, and the driving module (2) realizes the motor driving function. The control module (1) includes (3) DC-DC power supply module, (4) digital signal processing unit, (5) program and system parameter storage unit, (6) system communication interface, (7) driver working status and fault Indication unit, (8) data bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com