Efficient and multifunctional iron phosphate lithium battery equipment

A lithium iron phosphate battery, multi-functional technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of pole piece running deviation, coating machine belt running pole piece belt, pole piece scrapping, etc., to improve The effect of quality and performance, no sediment accumulation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

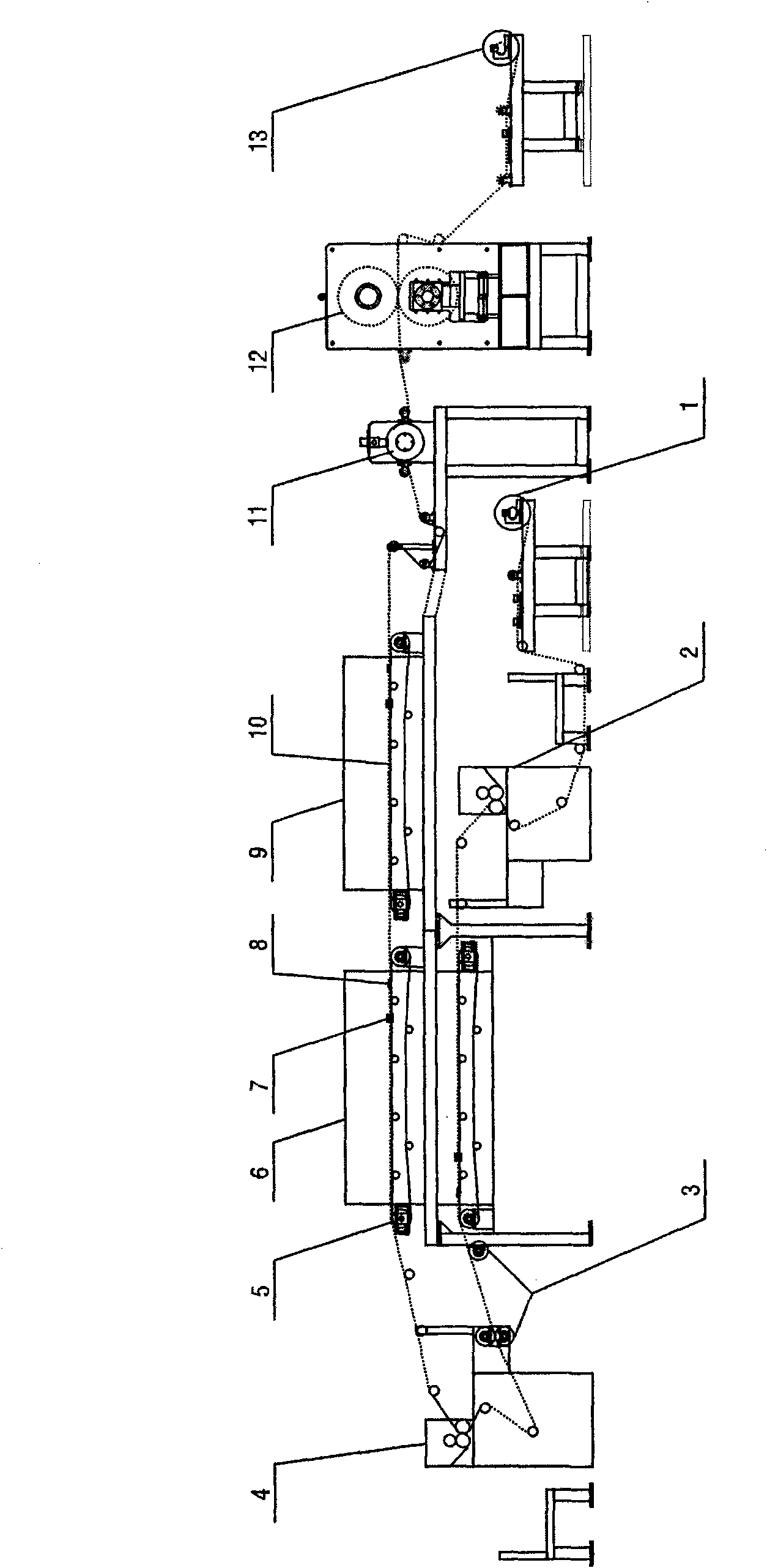

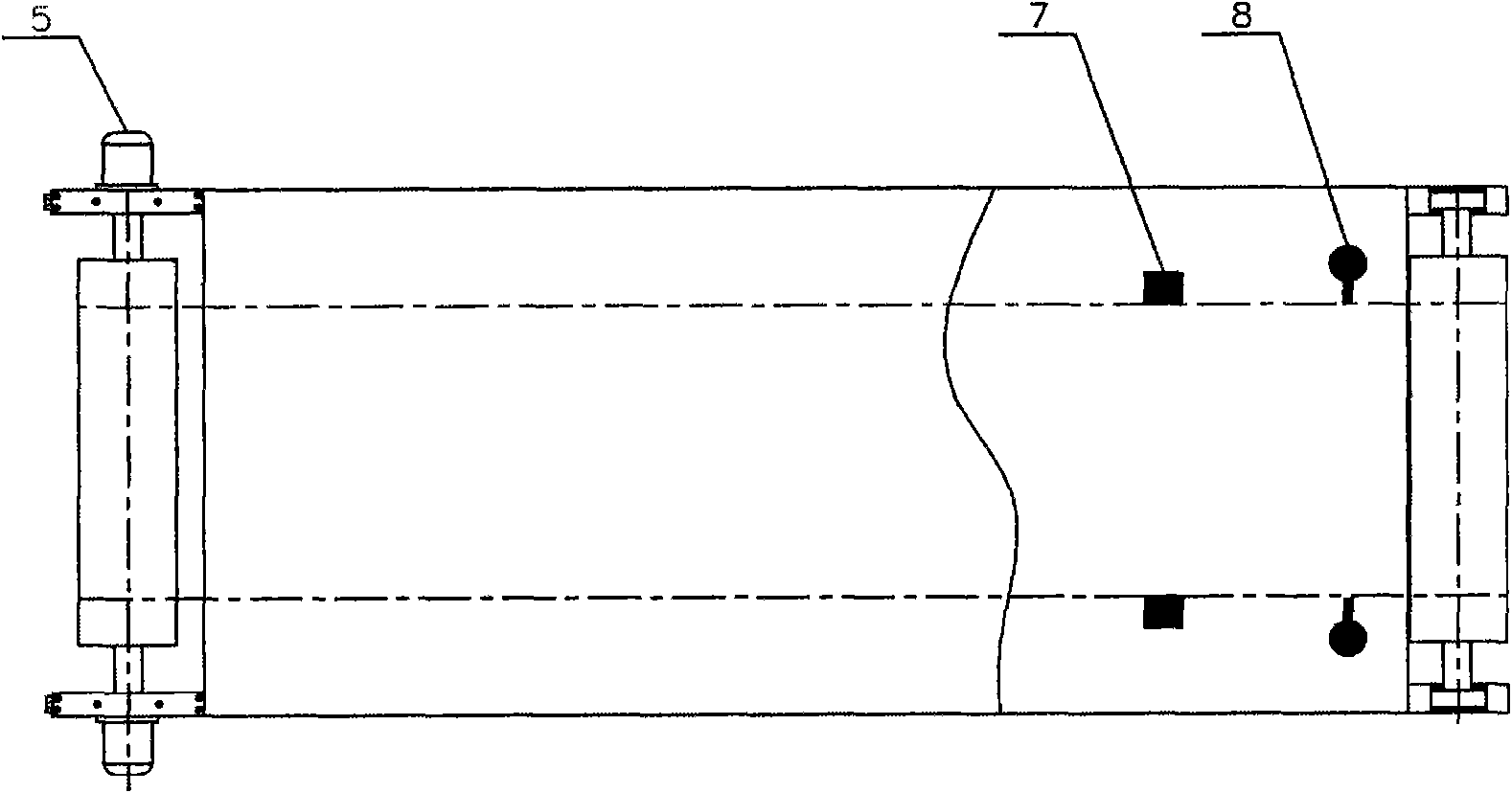

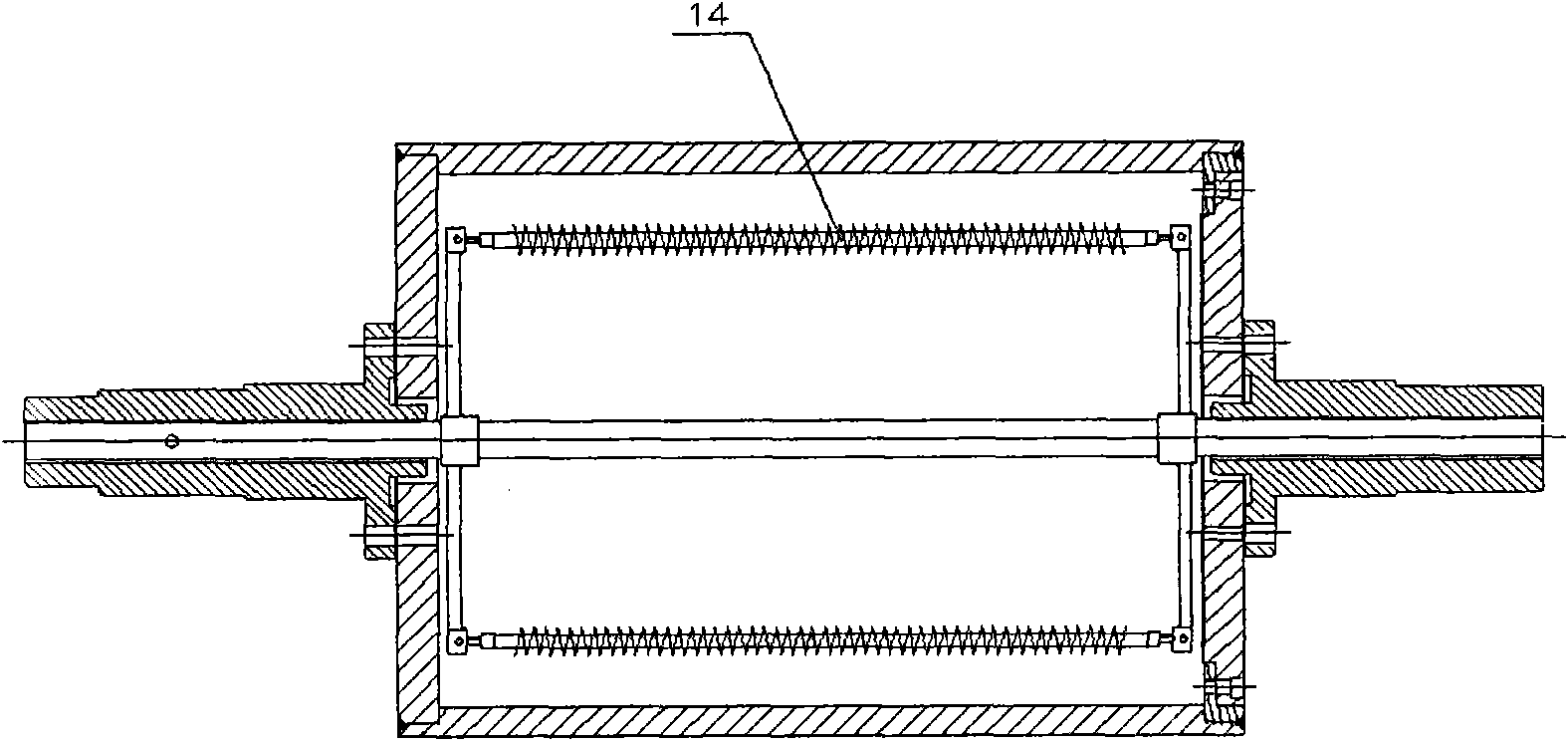

[0016] figure 1 , 2 Among them, a high-efficiency multifunctional lithium iron phosphate battery equipment, which includes an unwinding machine 1, a first surface coating machine 2, a Teflon conveyor belt 10, a drying box 6 and a cooling unit installed in sequence at the front end of the drying box 6 Roller 3, the second surface coating machine 4, servo motor 5, electric control device 7, dial indicator 8, cooling box 9, tablet press 12, winder 13, is characterized in that the first surface coating machine 2 Installed on the front end of the unwinding machine 1, the upper end of the trough 16 of the coating machine is equipped with a micro motor, and the micro mixer 17 is installed on the screw, one end is connected with the micro motor, the other end is installed on the trough 16, and the drying box 6 It is divided into upper and lower lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com