Preparation method of shell and shell prepared by method

A manufacturing method and shell technology, applied to chemical instruments and methods, devices for coating liquid on the surface, electrical equipment shells/cabinets/drawers, etc., can solve the problem of low surface free energy of polyphenylene sulfide, polyphenylene sulfide Problems such as restrictions on plastic materials and inability to attach paint layers to achieve the effect of increasing use value and added value, improving surface performance, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

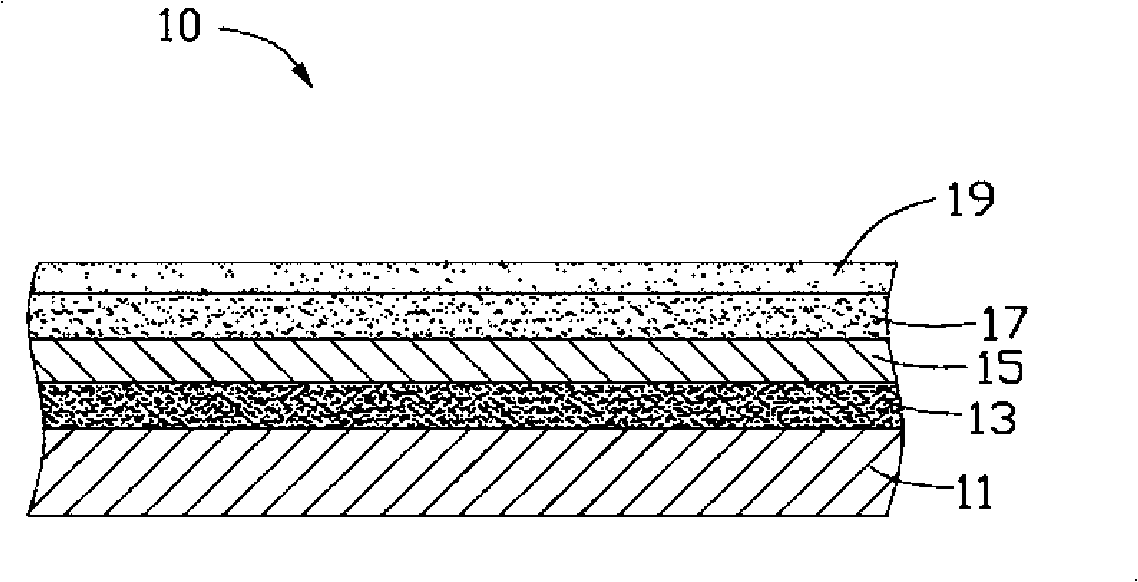

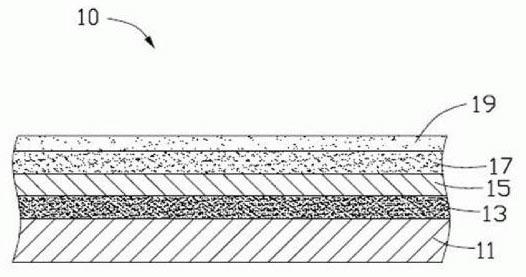

[0013] A preferred embodiment of the present invention, the manufacturing method of the casing includes the following steps:

[0014] A plastic base is provided, and the material of the plastic base is polyphenylene sulfide. The plastic matrix can be produced by injection molding.

[0015] The surface of the plastic substrate is subjected to plasma surface treatment. A plasma generator is provided. The plasma generator can be an inductively coupled plasma generator, a microwave surface wave plasma generator, an atmospheric glow plasma generator or a DC plasma generator. The source gas used in the plasma generator can be oxygen or nitrogen. The plastic substrate is placed in the plasma generator, and the plasma generated by the plasma generator acts on the surface of the plastic substrate, destroying the original chemical bonds between the surface molecules of the substrate, and at the same time interacting with the surface molecules of the plastic substrate The reaction pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com