Semi-solid deposition pressure welding device for dissimilar metals

A technology of pressure welding and dissimilar metals, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of metallurgical incompatibility, residual stress, large difference in mechanical properties, etc., and achieve flexible temperature adjustment and rapid heating , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

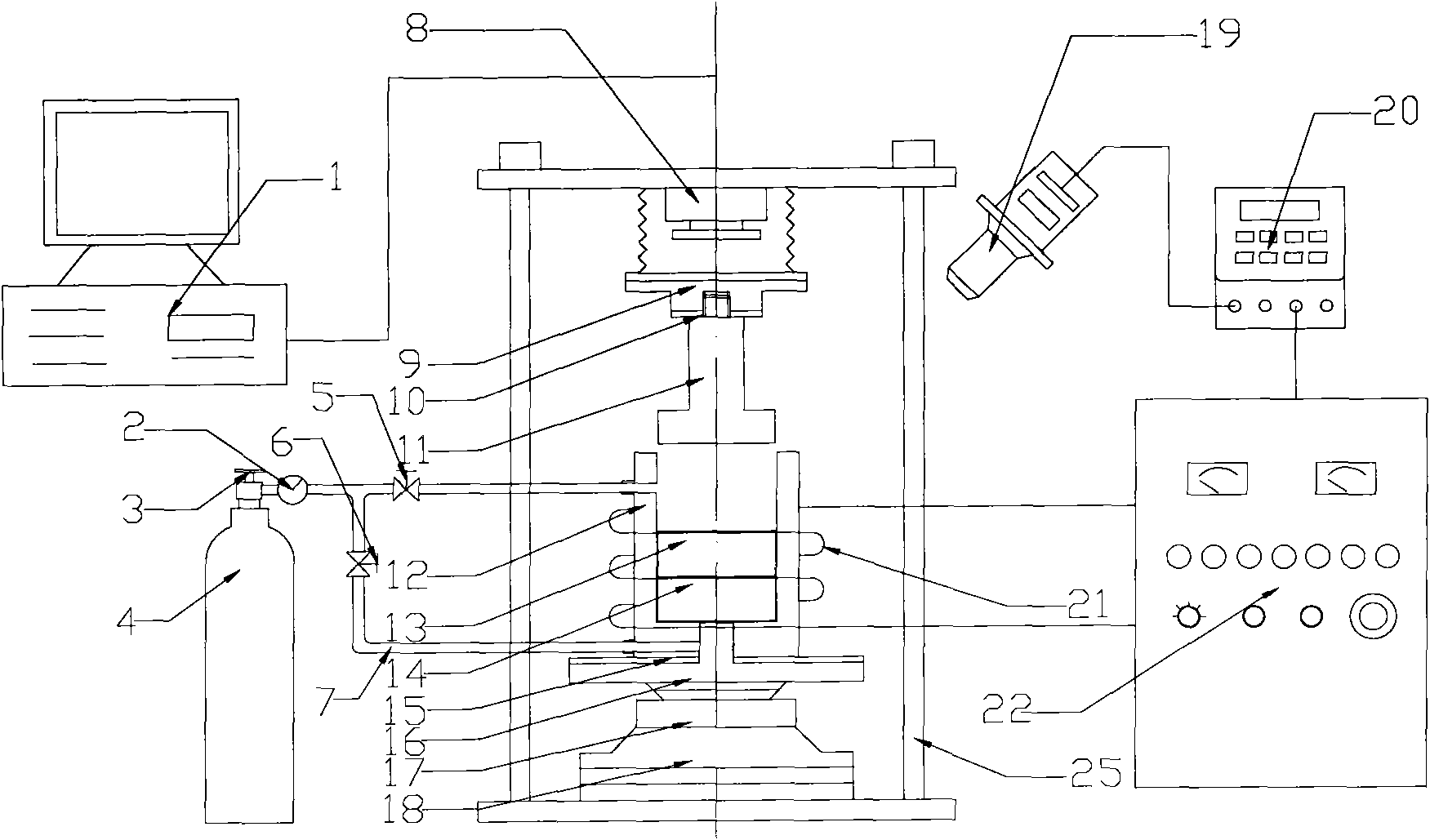

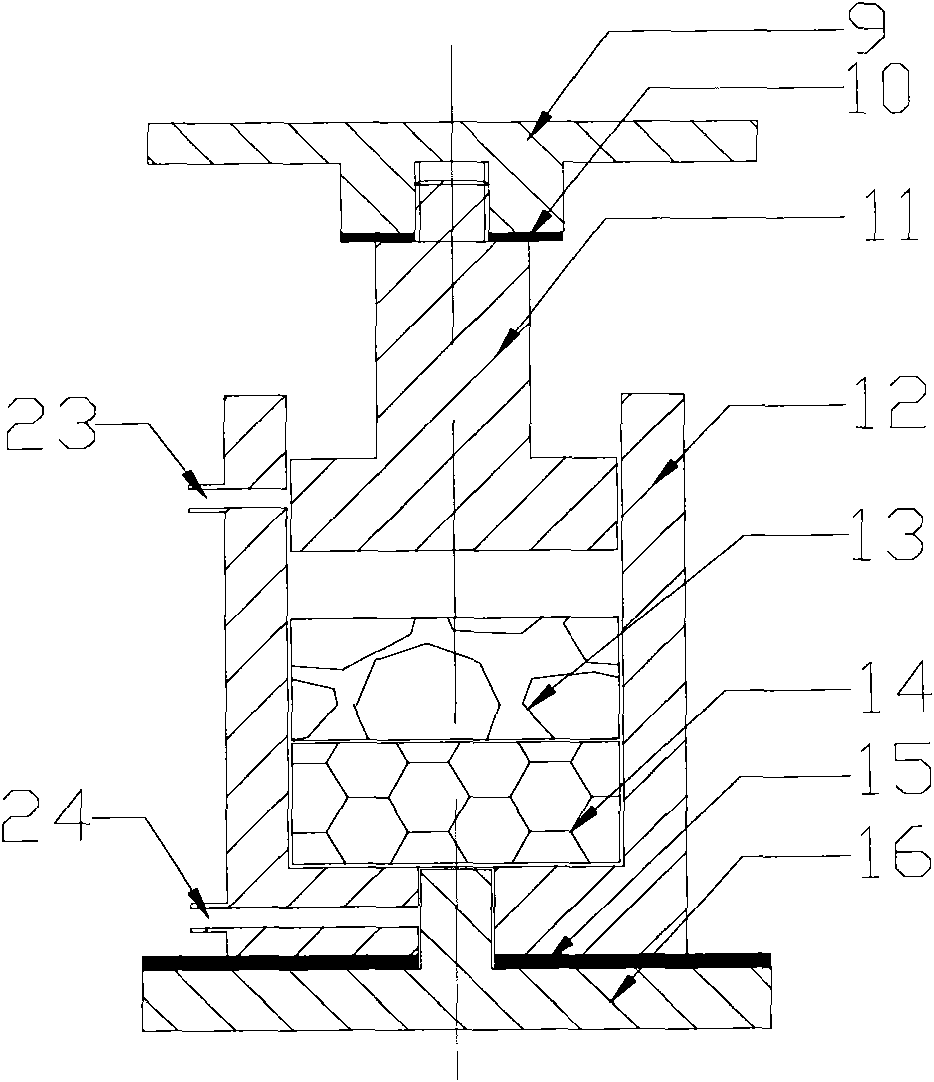

[0010] combine figure 1 , figure 2 The invention discloses a dissimilar metal semi-solid cladding pressure welding device, which comprises a pressure control device, a temperature control device, a gas protection device and a die device, the pressure control device is connected with the die device, and the pressure control device controls the pressure Passed to the compression molding device, the compression molding device exerts pressure on the welding sample; the temperature control device is connected to the compression molding device, and the temperature control signal adjusts the magnitude and on-off of the current of the induction heating coil 21, and controls the heating process of the compression molding device; The protection device is connected with the compression molding device, and the protection gas is input into the compression molding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com