High abrasion-resisting paper feed roll

A paper feed wheel, high wear-resistant technology, applied in the direction of pile separation, layered products, transportation and packaging, etc., can solve the problem of non-wear-resistant surface of the paper feed wheel, to achieve non-blooming paper, high wear resistance, The effect of not polluting the paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

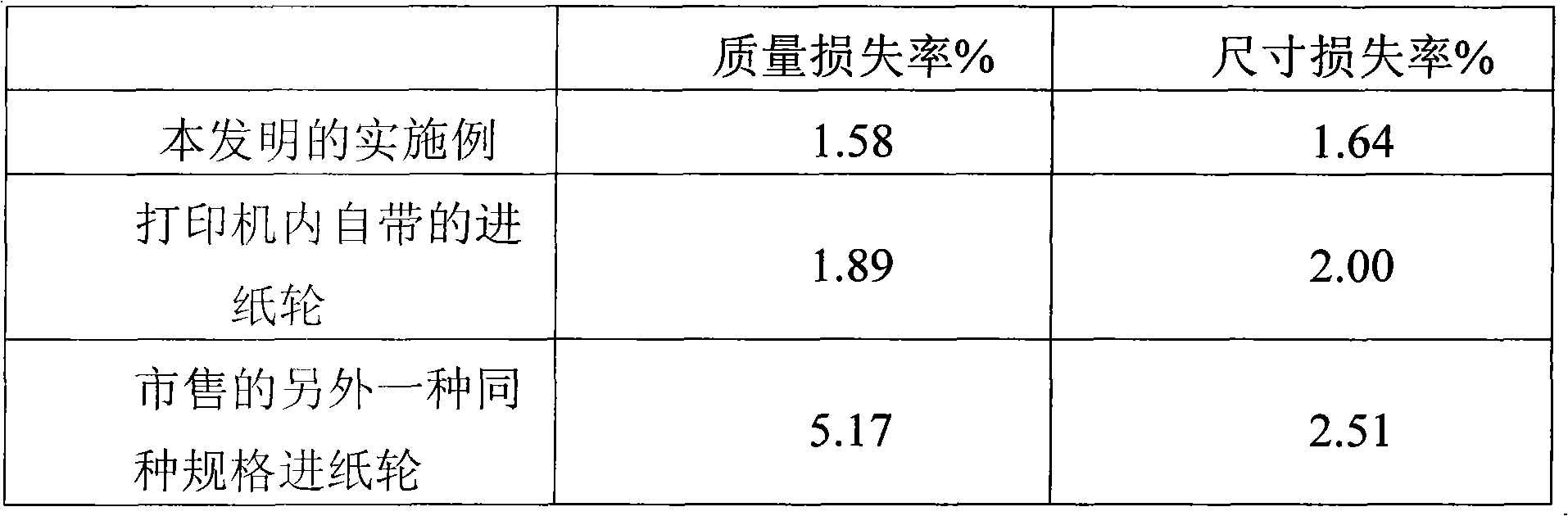

Examples

Embodiment Construction

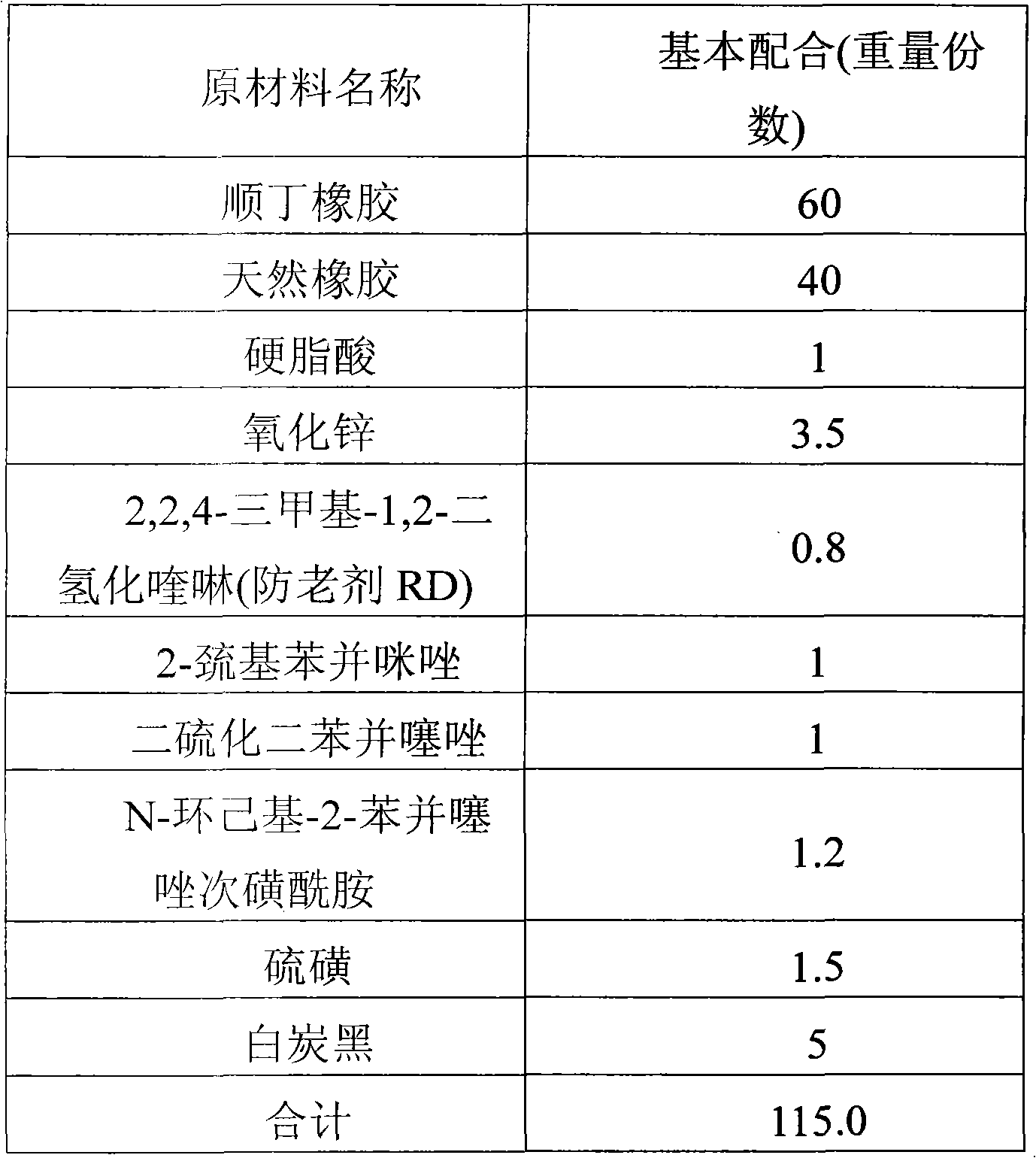

[0026] The invention relates to a high wear-resistant paper feed wheel, which is composed of a plastic skeleton and a rubber wheel or sleeve covered thereon, characterized in that the rubber wheel or sleeve is made of a rubber composition, and the rubber Composition includes:

[0027] a. Rubber with good wear resistance, which is butadiene rubber, natural rubber or a combination of the two;

[0028] b. A vulcanization system that does not bloom and is suitable for the two rubbers in a. or combinations thereof;

[0029] c. One or more antioxidants;

[0030] The total weight of rubber in the rubber composition is 100 parts; the weight of the rubber vulcanization system is 5-10 parts, preferably 6-8 parts; the weight of the antioxidant is 0.5-3 parts, most preferably The best dosage is 1-2 servings.

[0031] The rubber vulcanization system is a mixture of zinc oxide, stearic acid, dibenzothiazole disulfide, N-cyclohexyl-2-benzothiazole sulfenamide and sulfur. in:

[0032] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com