Vanadium-titanium vermicular graphite cast iron

A technology of vermicular graphite cast iron and vanadium titanium, which is applied in the field of material metallurgy and can solve the problems of high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

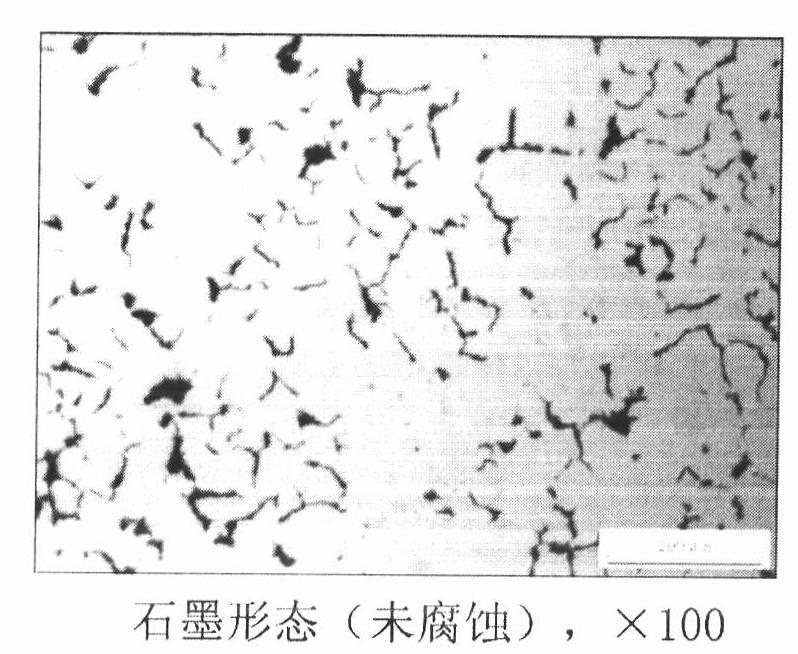

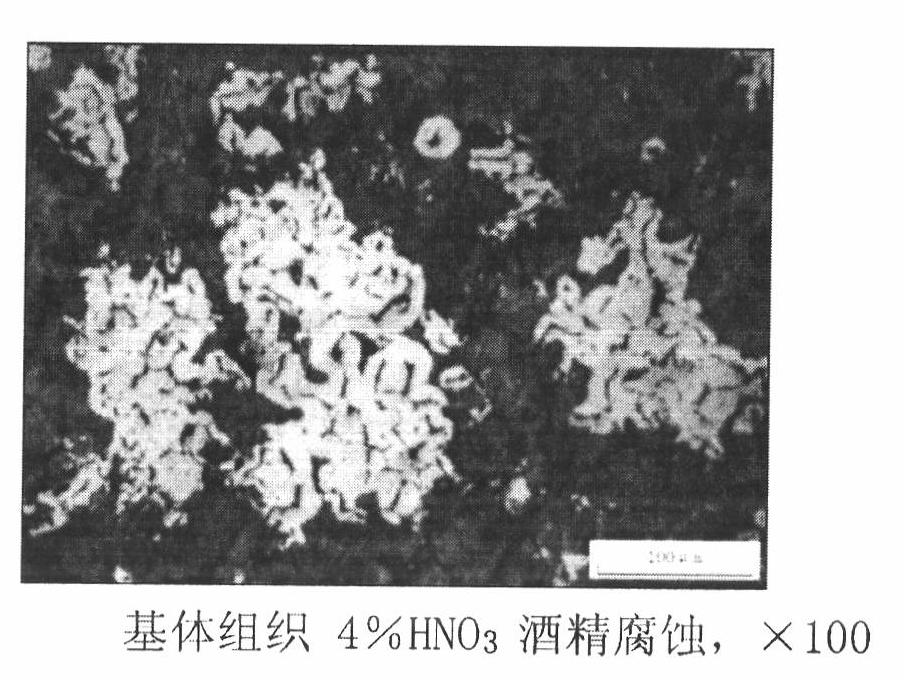

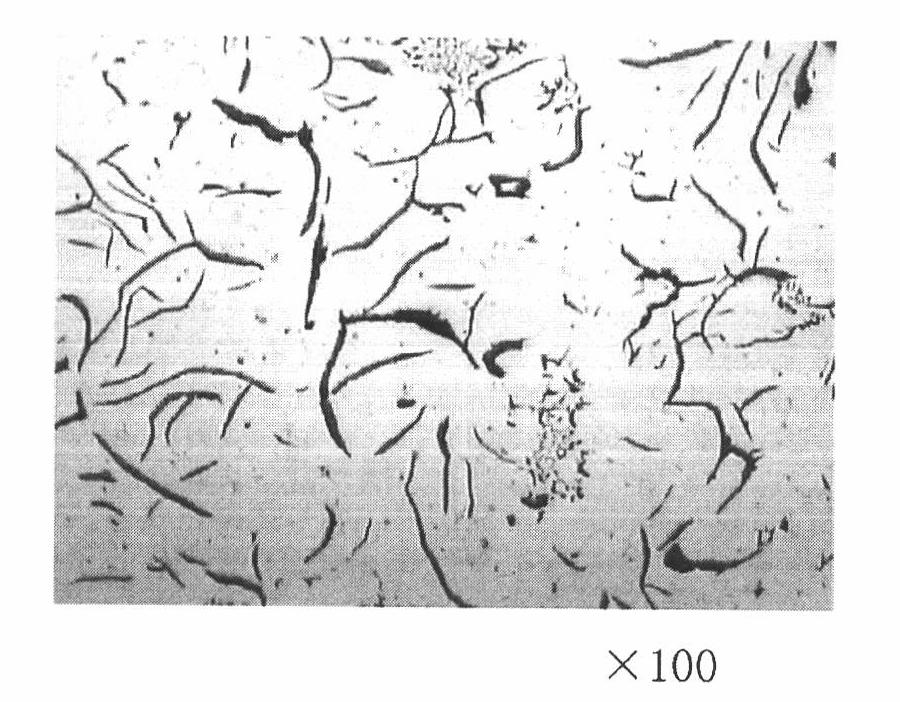

[0030] refer to Figure 1a and Figure 1b , it can be seen that the graphite form of vanadium-titanium vermicular graphite cast iron according to the present invention is mostly worm-like, and the graphite form of vanadium-titanium vermicular graphite cast iron in a among Fig. 1 is 90% vermicular graphite and 10% spherical graphite, Figure 1b The medium matrix structure is 70% pearlite; the composition of the vanadium-titanium compacted graphite cast iron according to the present invention is shown in Table 1, and the performance of the brake drum prepared by using the vanadium-titanium compacted graphite cast iron of the present invention is shown in Table 2.

[0031] The composition of various cast irons in table 1 comparative examples 1-3 and embodiment 1

[0032]

[0033] Performance of brake drum products prepared by various cast irons in Table 2 Comparative Examples 1-3 and Example 1

[0034]

[0035] It can be known from the above Table 2 that the various performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com