Ionic lead-acid cell repair protection solution

A lead-acid battery, repair fluid technology, applied in the direction of secondary battery repair/maintenance, etc., to achieve the effect of prolonging life, improving bonding force, and reducing self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

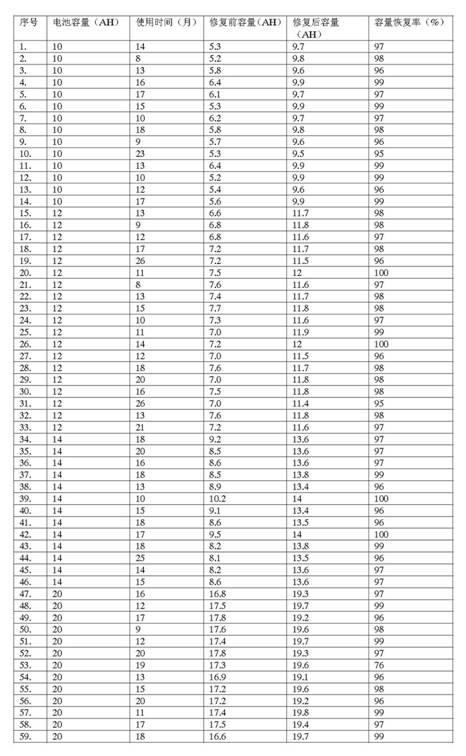

Embodiment 1

[0036] Ionic lead-acid battery protection repair solution, containing 3 parts of sodium sulfate, 5 parts of magnesium sulfate, 5 parts of wood powder, 0.05 parts of barium sulfate, 0.01 part of manganese dioxide, 1.5 parts of antimony potassium tartrate, 1 part of stannous sulfate, 2 parts of ascorbic acid , 1000 parts of pure water.

Embodiment 2

[0038] Ionic lead-acid battery protection repair solution, containing 5 parts of potassium sulfate, 15 parts of zinc sulfate, 5 parts of humic acid, 0.05 parts of strontium sulfate, 0.03 parts of manganese dioxide, 2 parts of tartaric acid, 0.5 parts of stannous sulfate, 0.5 parts of ascorbic acid, water 900 copies.

Embodiment 3

[0040] Ionic lead-acid battery protection repair solution, containing 4 parts of potassium sulfate, 10 parts of zinc sulfate, 3 parts of wood powder, 0.02 parts of strontium sulfate, 0.02 parts of manganese dioxide, 1.75 parts of antimony potassium tartrate, 0.75 parts of stannous sulfate, 1.5 parts of ascorbic acid , 950 parts of water.

[0041] The preparation method of repair liquid described in embodiment 1-3 is: 1. get sodium sulfate earlier and be dissolved in 1000 parts of water, form diluent; 2. get magnesium sulfate, barium sulfate, stannous sulfate, antimony potassium tartrate, wood powder, manganese dioxide Add it to the diluent in turn, heat and stir, and form a mixed solution after all the substances are dissolved; ③ After the above mixed solution is stable for 1 hour, add ascorbic acid to form the battery repair solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com