Daily-use double-layer ceramic bowl and preparation method thereof

A ceramic bowl and double-layer technology, applied in the field of ceramic material products, can solve the problems of not meeting the requirements of people's quality life, single modeling and decoration methods, large firing shrinkage, etc., and achieve simple and easy preparation method and firing range The effect of wide and high temperature deformation difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The bowl body is made of alumina ceramics, and the outer surface of the bowl body is covered with a glaze layer. The glaze weight composition of the glaze layer contains: 70% of silicon dioxide, 16% of aluminum oxide, 0.5% of calcium oxide, 4% of magnesium oxide, and 6% potassium, 1.5% sodium oxide and 2% titanium oxide, plus 20% fused silica, the glaze thickness is controlled at 0.6-1mm.

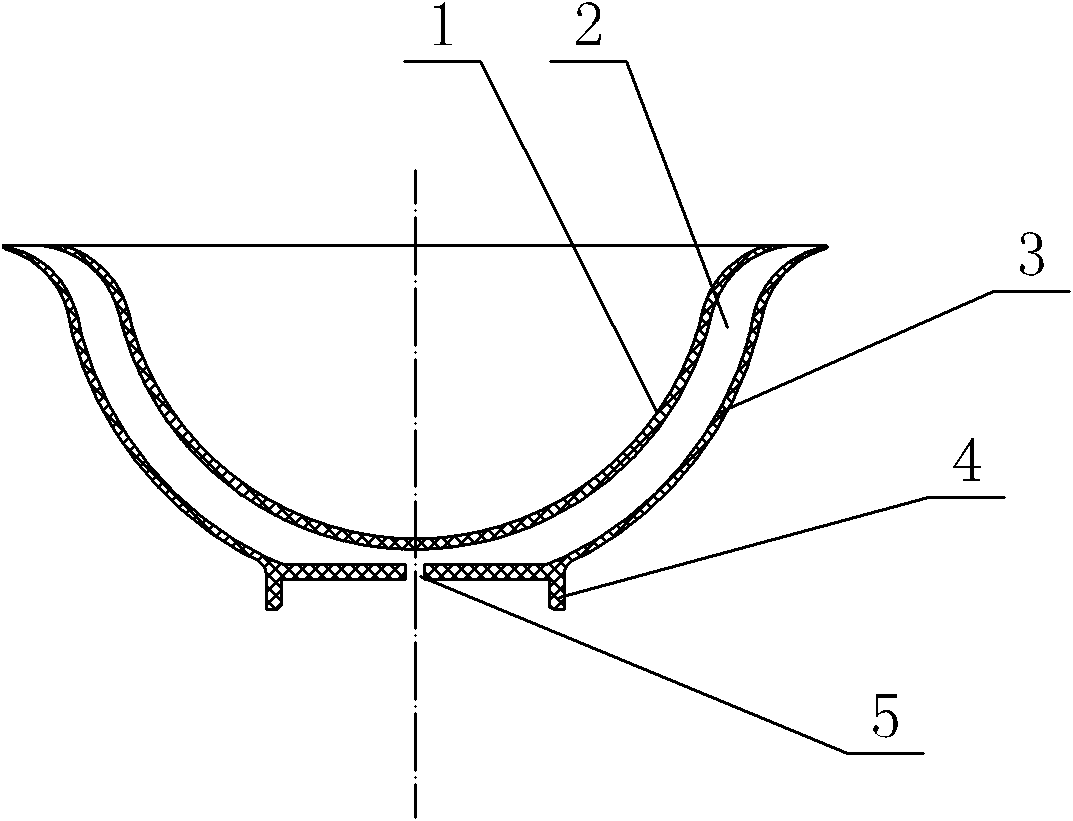

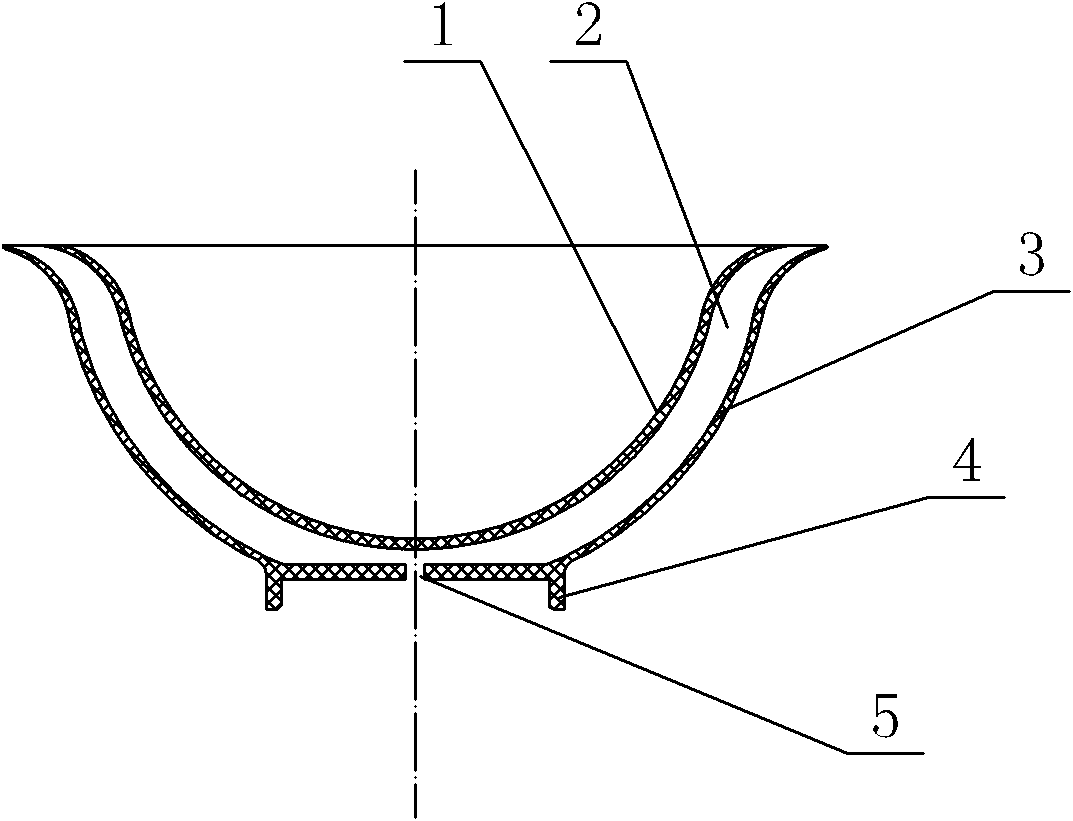

[0028] The molding adopts a grouting molding method, and the outer bottom (the outer bottom and the annular support foot 4) is formed separately, and then the outer bottom is combined with the bowl body by bonding.

[0029] Firing: bisque firing temperature 1520--1550°C, holding time: 2.5 hours;

[0030] The glaze firing temperature is 1300--1280°C, and the holding time is 2 hours.

[0031] Product performance parameters:

[0032] Bending strength 4000MPa Bulk density 3.85g / cm 3

[0033] Fracture toughness 4.00MPa.M 1 / 2 , hardness 14.52GPa

[0034] Glaze Whiteness: 85%; Transpa...

Embodiment 2

[0036] The bowl body is made of zirconia ceramics, and the outer surface of the bowl body is covered with a glaze layer, in which the glaze weight composition of the glaze layer contains: 62-75% of silicon dioxide, 15% of alumina, 1% of calcium oxide, and 5% of magnesium oxide , 7% potassium oxide, 1.7% sodium oxide and 1.3% titanium oxide, plus 15% fused silica, and the glaze thickness is controlled at 0.5-0.8mm.

[0037] The molding adopts a grouting molding method, and the outer bottom (the outer bottom and the annular support foot 4) is formed separately, and then the outer bottom is combined with the bowl body by bonding.

[0038] Firing: bisque firing temperature 1500--1530 ℃, holding time: 2.5 hours;

[0039] The glaze firing temperature is 1200--1280°C, and the holding time is 1.5 hours.

[0040] Product performance parameters:

[0041] Bending strength 4000MPa Bulk density 3.80g / cm 3

[0042] Fracture toughness 4.10MPa.M 1 / 2 , hardness 14.51GPa

[0043] Glaze Wh...

Embodiment 3

[0045] The bowl body is made of quartz ceramics, and the outer surface of the bowl body is covered with a glaze layer. The glaze weight composition of the glaze layer contains: silicon dioxide 69%, aluminum oxide 16%, calcium oxide 0.6%, magnesium oxide 4.4%, potassium oxide 6%, 1.5% sodium oxide and 2.5% titanium oxide, plus 25% fused silica, the glaze thickness is controlled at 0.1-1.5mm.

[0046] The molding adopts a grouting molding method, and the outer bottom (the outer bottom and the annular support foot 4) is formed separately, and then the outer bottom is combined with the bowl body by bonding.

[0047] Firing: bisque firing temperature 1500--1540 ℃, holding time: 1.5 hours;

[0048] Glaze firing temperature 1350--1380 ℃, holding time: 2 hours.

[0049] Product performance parameters:

[0050] Bending strength 4000MPa Bulk density 3.82g / cm 3

[0051] Fracture toughness 4.05MPa.M 1 / 2 , hardness 14.52GPa

[0052] Glaze Whiteness: 86%; Transparency: 2.16%; Glaze Glos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com