A wafer manufacturing device for a solar battery cell and a wafer manufacturing method using the same

A solar cell and manufacturing device technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as difficulty in increasing solar power generation efficiency and increase in operating hours, so as to improve power generation efficiency, reduce popularization costs, and minimize manufacturing costs effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in further detail based on the drawings.

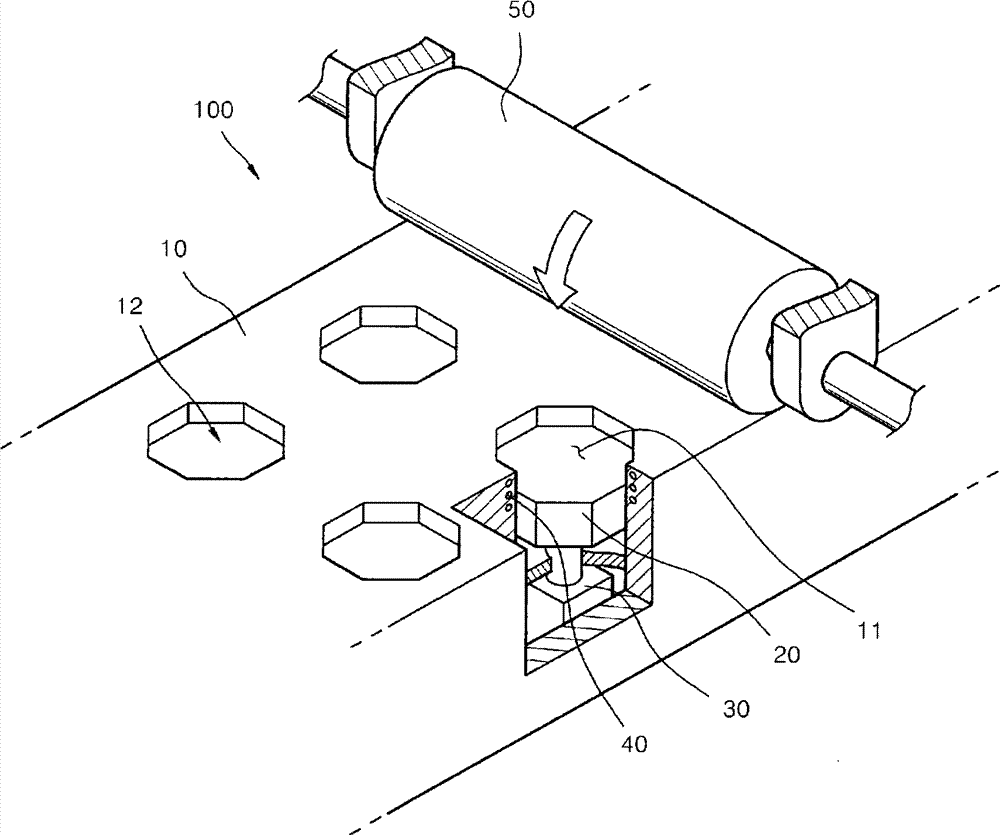

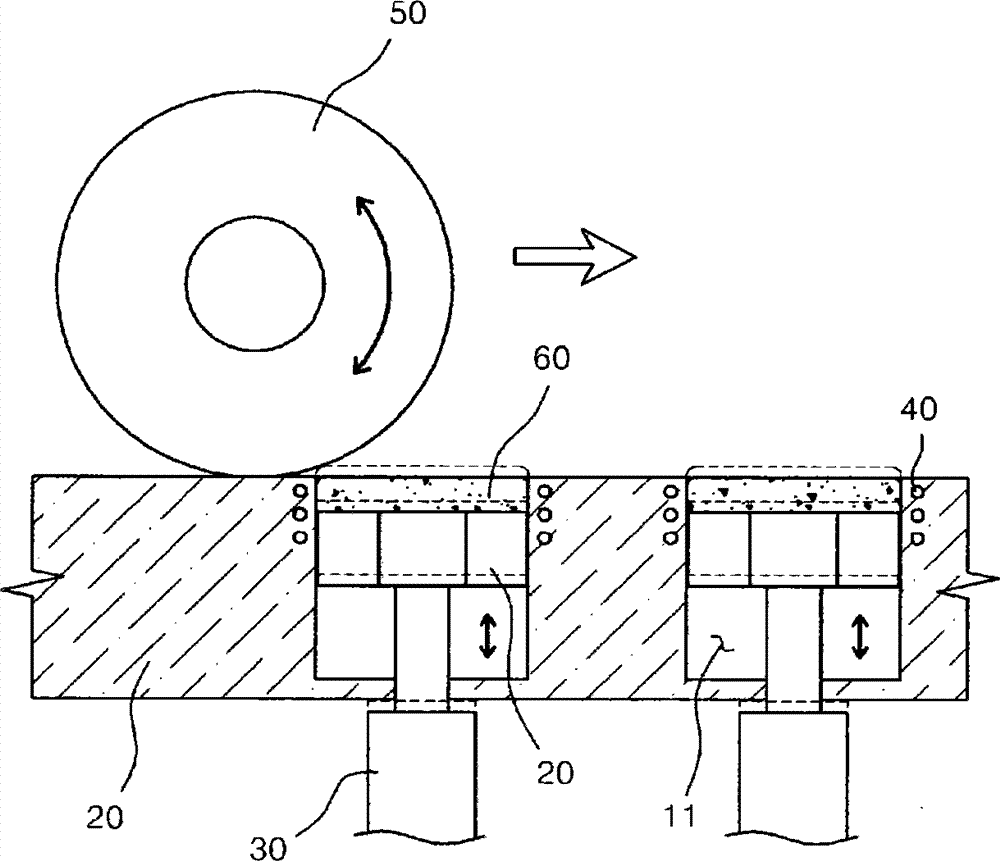

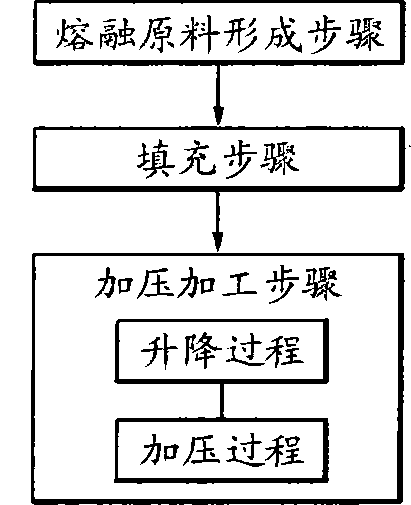

[0022] refer to figure 1 and figure 2 A solar cell wafer manufacturing apparatus 100 (hereinafter referred to as “wafer manufacturing apparatus”) of the present invention includes a mold 10 , a lifting member 20 , a driver 30 , a heater 40 , and a pressurizing device.

[0023] The mold 10 is formed with a casting mold 12 corresponding to the wafer shape of the solar cell unit on the upper surface, and the cross section of the wafer in this embodiment is hexagonal, so a hexagonal filling groove is formed from the upper surface of the mold 10 to the bottom 11. The lifting member 20 is provided in the filling tank 11 so as to be able to move up and down freely, thereby forming a filling space filled with the molten wafer raw material 60 , that is, a mold 12 .

[0024] Inside the mold 10 is provided an installation space where the driver 30 for raising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com