Method and device for absorbing waste chlorine generated in lithium production process by utilizing iron powder

A production process, chlorine gas technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as environmental pollution around chlorine water, economic losses, waste of chlorine resources, etc., achieve economical improvement, solve environmental pollution, The effect of saving chlorine resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

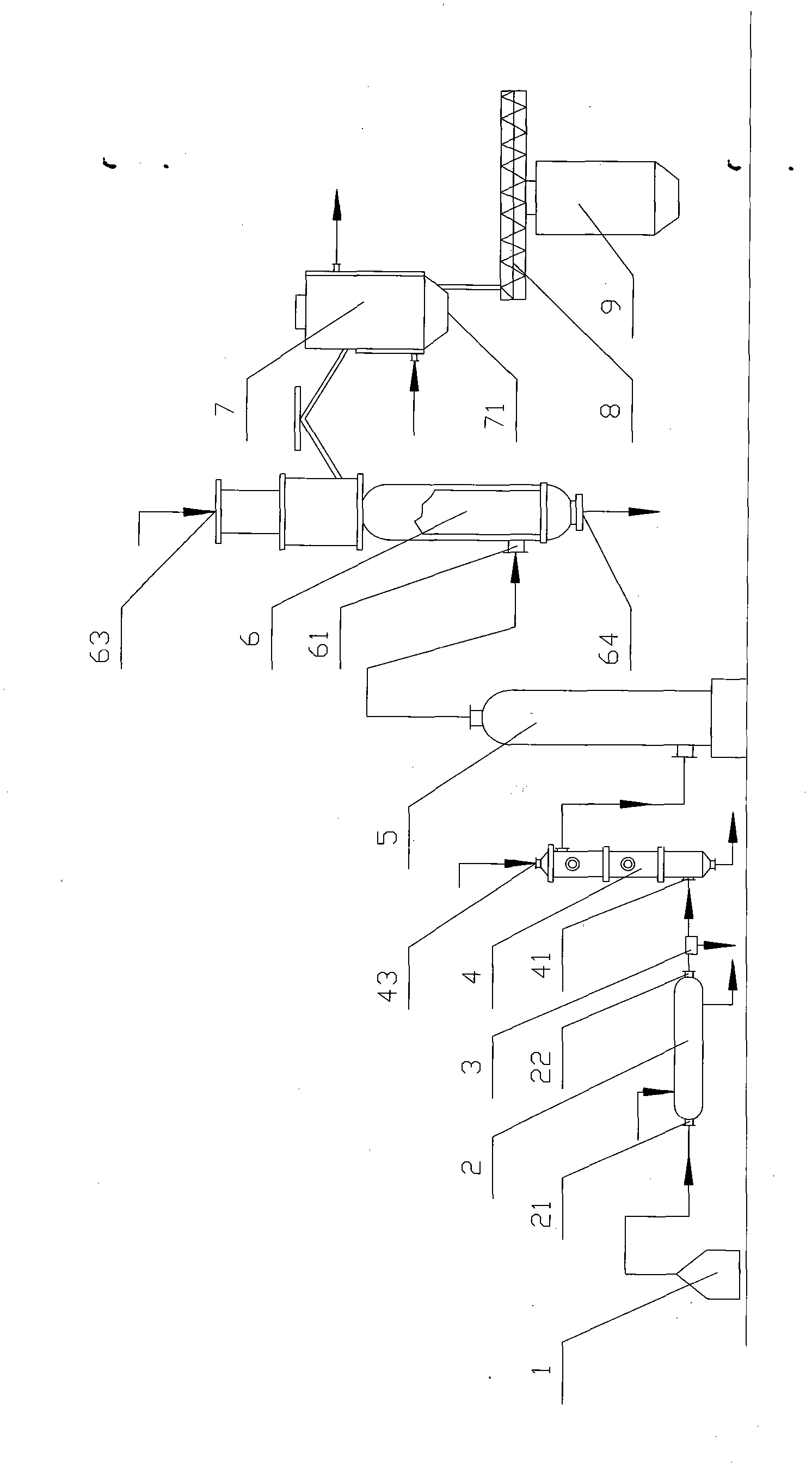

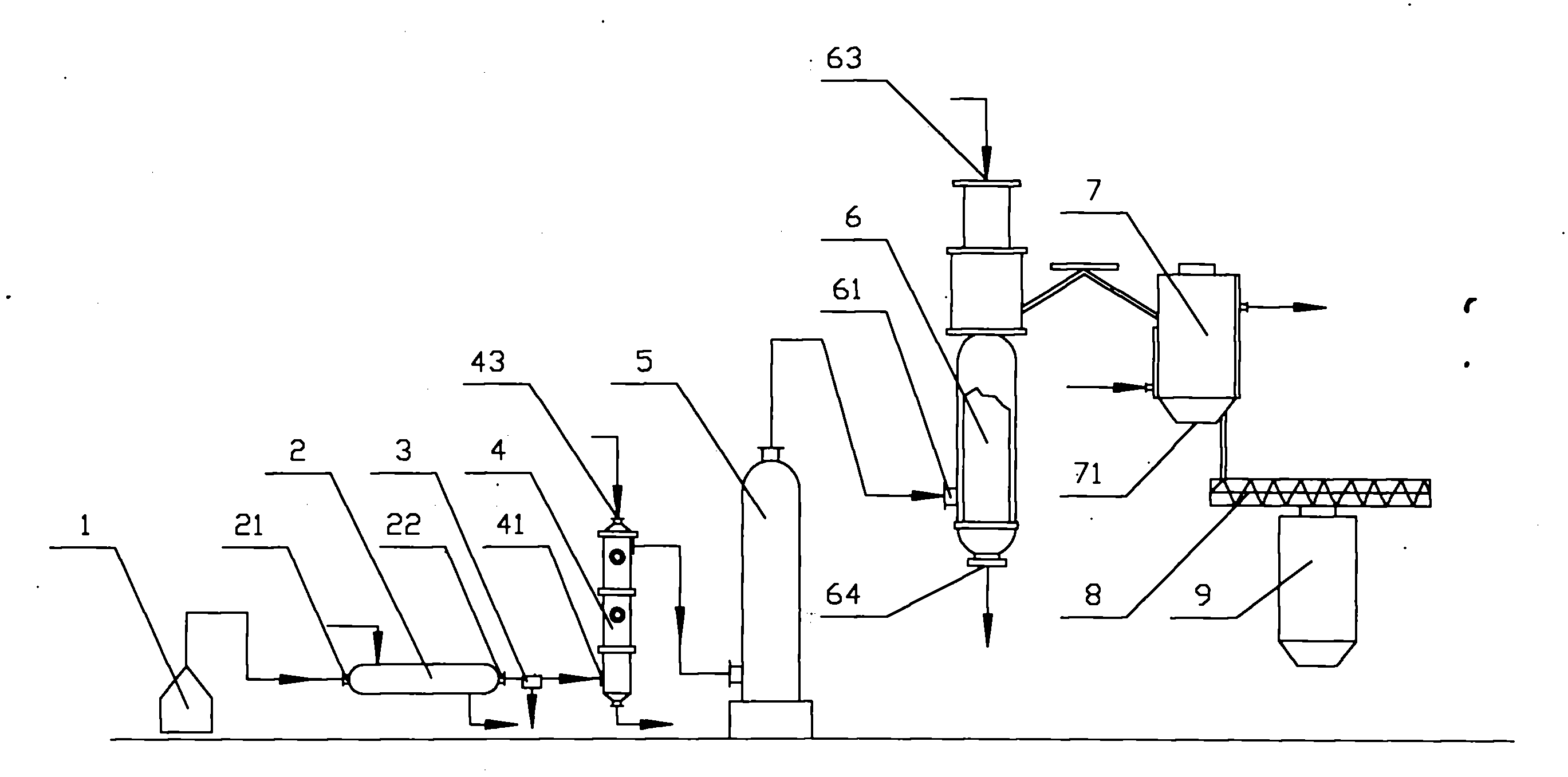

[0021] like figure 1 As shown, the present invention provides a method for utilizing iron powder to absorb waste chlorine gas produced in the lithium production process and a device thereof, wherein the method for utilizing iron powder to absorb waste chlorine gas produced in the lithium production process includes the following steps:

[0022] 1) For the collection of waste chlorine gas, in a fully sealed electrolytic cell, a collector is connected to the upper end of the anode of the electrolytic cell, and the negative pressure is 1*10 -2 Lead the waste chlorine gas out of the tank;

[0023] 2) cooling the waste chlorine gas to 15°, condensing and separating part of the water therein;

[0024] 3) using concentrated sulfuric acid to further dry the cooled chlorine;

[0025] 4) Feed the waste chlorine gas into the chlorination furnace and react with iron powder to generate gaseous ferric chloride;

[0026] 5) cooling the gaseous ferric chloride to obtain ferric chloride cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com