Limiting mandrel for mandrel pipe mill and manufacturing method thereof

A technique for limiting mandrels and manufacturing methods, which is applied in metal rolling, manufacturing tools, metal rolling, etc., and can solve problems such as heavy weight, uneven wear of rolls, and uneven wall thickness on the upper and lower sides of steel pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

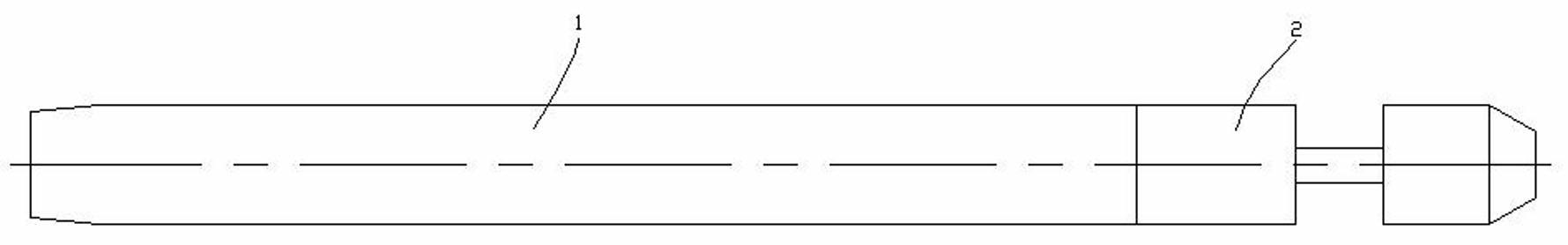

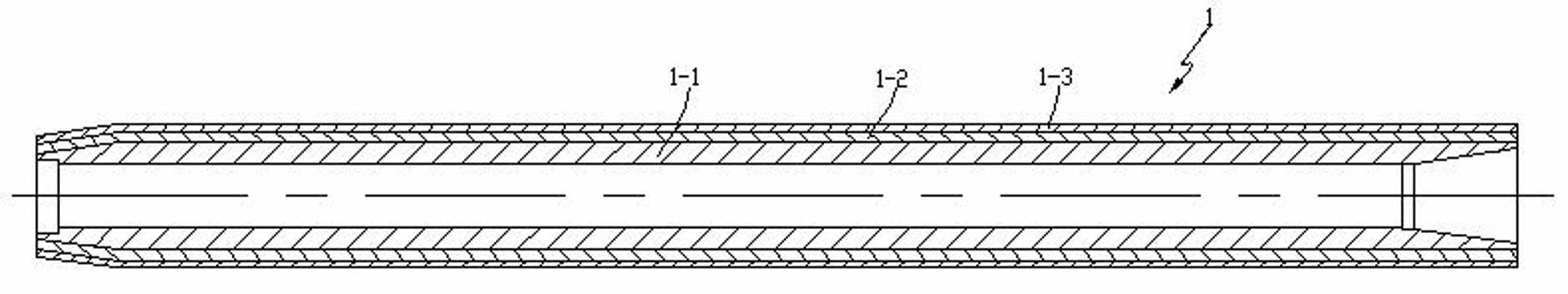

[0021] see figure 1 , 2 A stop mandrel for a continuous rolling mill is shown, including a rolling working section 1 and a tail section 2 threaded with the rolling working section 1. The rolling working section 1 consists of a cylindrical base body 1- 1 and a surfacing layer 1-2 fixedly bonded to the outer wall of the cylindrical substrate 1-1 and a chrome-plated layer 1-3 located on the surface of the surfacing layer 1-2; the cylindrical substrate 1-1 Low-alloy steel is used; the material used in the surfacing layer 1-2, its components are calculated by weight percentage, consisting of C 0.30-0.45%, Si 0.7-1.2%, Mn≤0.60%, Cr 4.5-5.5 %, V 0.8~1.2%, Mo 1.0~1.75%, Ni≤0.25%, P≤0.03%, S≤0.03% and the balance Fe.

[0022] In the present invention, the low-alloy steel used for the cylindrical base 1-1 and the material used for the tail section 2 are preferably 42CrMo.

[0023] In the present invention, the manufacturing method of the stopper mandrel for continuous rolling mill in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com