Special fertilizer for rice leaf surfaces and application thereof

A special fertilizer and foliar technology, applied in the field of rice foliar fertilizer, can solve the problems of shortage, deterioration of rural ecological environment, and decline of soil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

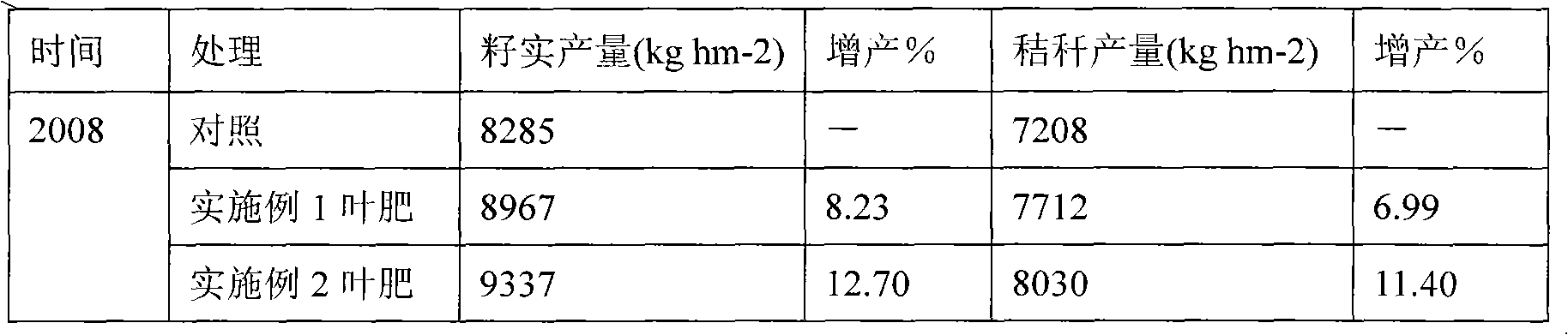

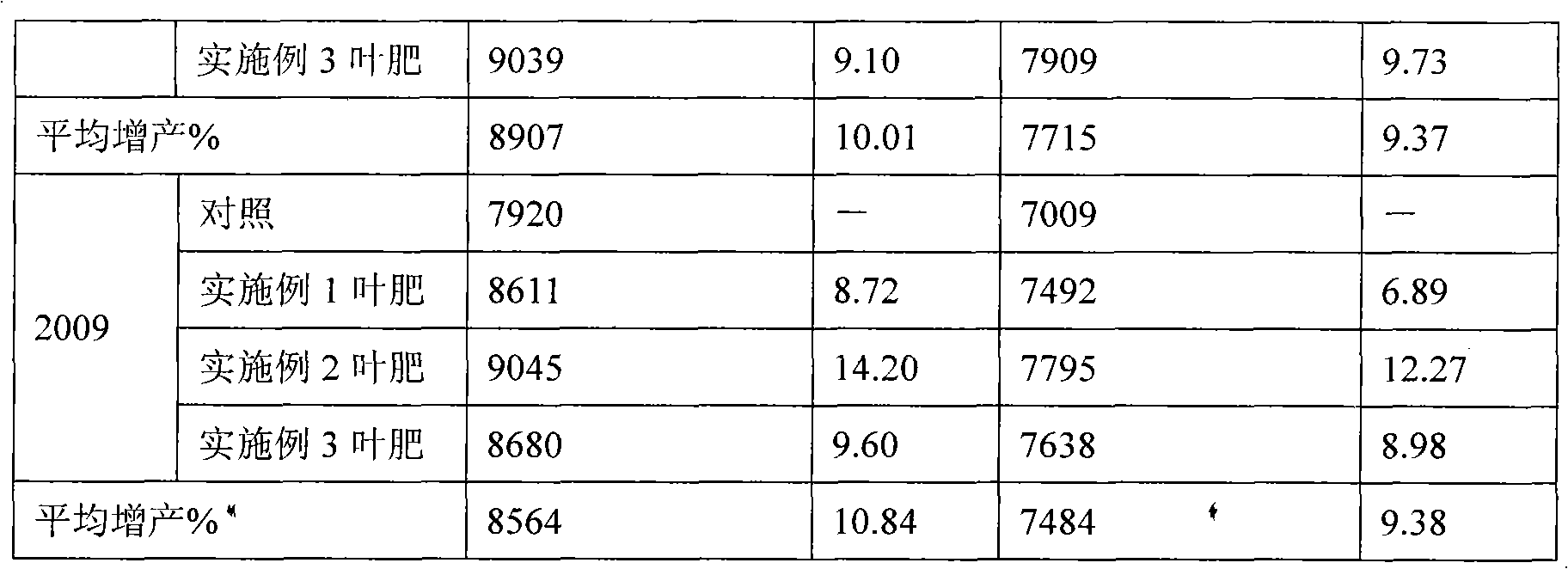

Examples

Embodiment 1

[0014] Each material composition in every 1000 milliliters of foliar fertilizers of table 1 embodiment 1

[0015] Substance name

[0016] Get 160 milliliters of 15.0% calcium magnesium aqueous solution (with calcium nitrate and magnesium nitrate as raw material, be mixed with the mass concentration of calcium and magnesium element as 7.5% aqueous solution) and 150 milliliters of 5% trace element solution (with ferric sulfate, sulfuric acid Copper, zinc sulfate, ammonium molybdate, manganese sulfate are raw materials, after the mass concentration of iron, copper, zinc, molybdenum, manganese element is 1% be mixed with) mixed, add 150 milliliters of complexing agent solutions of 20% and 250 ml of 50% related amino acid mother liquor, stirred for 10-15 minutes, then added 100 ml of 30% chitosan solution, stirred for another 10-15 minutes, added 100 ml of 3.0% surfactant (Tween 20), then added water 90 mL to make a total volume of 1000 mL and stir for 10-15 minutes. The...

Embodiment 2

[0018] Each material composition in every 1000 milliliters of foliar fertilizers of table 2 embodiment 2

[0019] Substance name

[0020] Get 100 milliliters of 15.0% calcium and magnesium aqueous solution (with calcium nitrate and magnesium nitrate as raw material, be mixed with the mass concentration of calcium and magnesium element as 7.5% aqueous solution) and 100 milliliters of 5% trace element solution (with ferric sulfate, sulfuric acid Copper, zinc sulfate, ammonium molybdate, manganese sulfate are raw materials, after the mass concentration of iron, copper, zinc, molybdenum, manganese element is 1% be mixed with) mixing, add 125 milliliters of complexing agent solutions of 20% and 150 ml of 50% related amino acid mother liquor, stirred for 10-15 minutes, then added 70 ml of 30% chitosan solution, stirred for another 10-15 minutes, added 100 ml of 3.0% surfactant (Tween 80), then added water 355 ml to make a total volume of 1000 ml and stir for 10-15 minutes....

Embodiment 3

[0022] Each material composition in every 1000 milliliters of foliar fertilizers of table 3 embodiment 3

[0023] Substance name

[0024] Complexing agent EDTA

[0025] Get 200 milliliters of 15.0% calcium and magnesium aqueous solution (with calcium nitrate and magnesium nitrate as raw material, be mixed with the mass concentration of calcium and magnesium as 7.5% aqueous solution) and 200 milliliters of 5% trace element solution (with ferric sulfate, copper sulfate , zinc sulfate, ammonium molybdate, and manganese sulfate are raw materials, and the mass concentration of iron, copper, zinc, molybdenum, and manganese elements is 1% to be mixed with an aqueous solution) After mixing, add 140 milliliters of complexing agent solutions of 25% and 50 % related amino acid mother liquor 240 milliliters, stirred 10-15 minutes, then added 120 milliliters of chitosan solutions of 30%, stirred again 10-15 minutes, added 100 milliliters (Tween 20) of surfactants of 3.0%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com